An expandable packer and method of using the same

A packer and expansion technology, applied in sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve the problem of limited ability of packer to withstand pressure difference, seal failure, and packer loss of seal and other problems, to achieve the effect of improving sealing and stability, improving the ability to withstand pressure difference, and strong ability to withstand pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0040]It should be explained that the structure, proportion, and sizes attached to the figures attached to this manual are only used to cooperate with the content revealed in the instructions to understand and read from those who are familiar with this technology. The limited conditions, the modification of any structure, the change of the proportion relationship, or the adjustment of the size, without affecting the effects of the present invention and the purpose that can be achieved, should Within range.

[0041] At the same time, the terms cited in this description such as "up", "down", "left", "right", "middle" and "one" are only for easy narratives, not used to limit this. The scope of the invention can be implemented, and the change or adjustment of its relative relationships. Under the content of no substantial changes, it is also regarded as the category of the present invention.

Embodiment 1

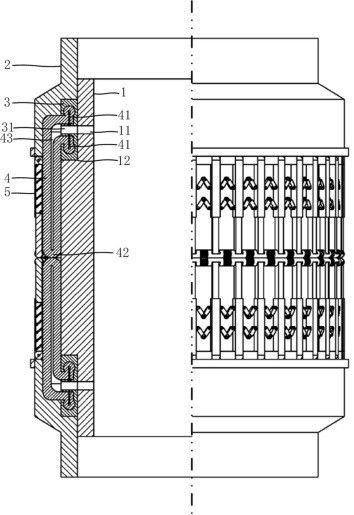

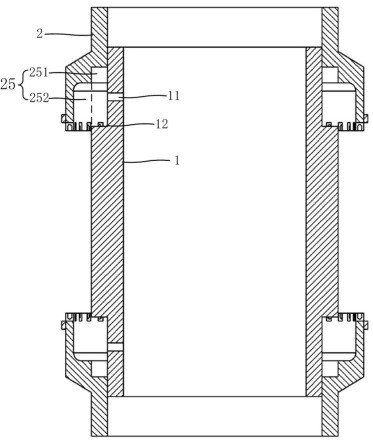

[0043] Bind figure 1 To attach image 3 , This embodiment provides an expansion septor, including Central Pipe 1, which is connected to connecting connectors 2 at both ends of the central pipe 1. Inside the ring -shaped space 25 is fixed with a sealing ring 3 that is fitted with the outer wall of the center pipe 1. The ring of the ring, and the sealing liquid storage cavity 43 is together with the sealing ring 3. The center pipe 1 has the first hole 11 on the center pipe 1. The sealing ring 3 is provided with the first -pass hole 11 and the second pass hole 31 of the storage liquid cavity 43.

[0044] In the above -mentioned technical scheme, the inner ring wall of the sealing ring 3 is preferably set up two sealing ring slots 312, and the two sealing ring slots 312 are located on the upper and lower sides of the second and second pores 31, respectively. In the circle, the O -type sealing ring is closely replaced by the central pipe 1, thereby further improving the seal between the...

Embodiment 2

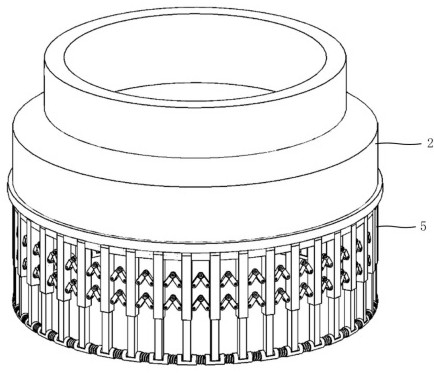

[0054] Bind figure 1 To attach Figure 10 , This embodiment provides an expansion septor. On the basis of embodiment 1, a support structure of rubber tube 4 is added. This supporting structure can not only limit the axial expansion level of the rubber cylinder 4, increase the sedentary septum The sealing stability of the device in the high -voltage difference can also promote the rowing efficiency of the rubber cylinder 4 during unblocking and achieve rapid unblocking. The specific technical solution is as follows,

[0055] like Figure 4 As well as Figure 5 and Image 6 Show, the connection head 2 round hinge multiple of multiple support rods 5, the hinge is equipped with twist spring 24, the twist spring 24 connects the connection head 2 at the other end, and the other end is connected to the support rod 5. The supporting rod 5 is close to the part of the ring -shaped space 25 in the tapem 4, and the expansion of the rubber cylinder 4 can be rotated from the vertical state to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com