Converter trunnion area furnace lining erosion part maintenance method and use method after maintenance

A furnace lining erosion and trunnion technology is applied in the field of converter furnace condition maintenance technology, which can solve the problems affecting the maintenance effect of the furnace lining erosion part in the trunnion area of the converter, the high frequency of gunning operations, and the easy falling off of furnace repair bricks, so as to avoid the furnace machine. Matching contradictions, safe and reliable cost, and the effect of reducing the frequency of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

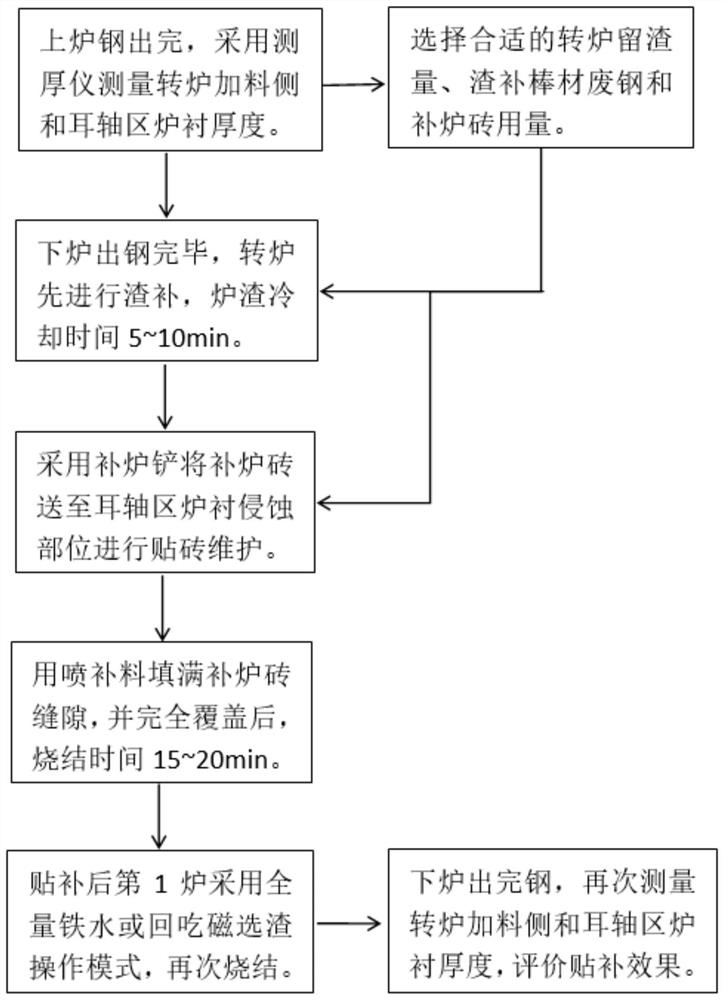

[0049] like figure 1 As shown, in this embodiment, a method for maintaining the eroded part of the furnace lining in the trunnion area of the converter and a method for using it after maintenance, specifically:

[0050] (1) 1 furnace of steel before tiling and maintenance, the steel tapping is completed, the steel tapping volume is 68.2t, after the converter is normally splashed with slag to protect the furnace, the slag in the furnace is cleaned. Use a laser thickness gauge to measure the lining thickness of the converter feeding side and the left and right trunnion areas. The measured lining thicknesses of the converter feeding side, left trunnion area and right trunnion area are respectively: 497mm, 538mm and 530mm, that is, the standard value of 650mm for the new lining In comparison, 153mm, 112mm and 120mm were eaten respectively.

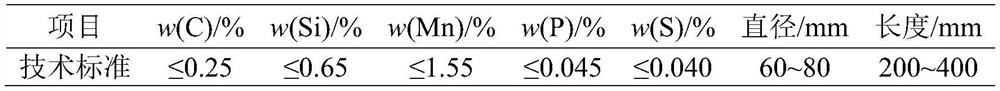

[0051] (2) Put 3.5t of clean bar scrap into the slag replenishment hopper, control the amount of slag remaining in the subsidized furnace ...

Embodiment 2

[0059] like figure 1 As shown, in this embodiment, a method for maintaining the eroded part of the furnace lining in the trunnion area of the converter and a method for using it after maintenance, specifically:

[0060] (1) 1 furnace of steel before tiling and maintenance, the steel tapping is completed, the steel tapping volume is 68.1t, and the slag in the furnace is cleaned after the converter is normally splashed with slag to protect the furnace. Use a laser thickness gauge to measure the lining thickness of the converter feeding side and the left and right trunnion areas. The measured lining thicknesses of the converter feeding side, left trunnion area and right trunnion area are: 499mm, 438mm and 396mm respectively, that is, the standard value of 650mm for the new lining In comparison, 151mm, 212mm and 254mm were eaten respectively.

[0061] (2) Put 3.6t of clean bar steel scrap into the slag replenishment hopper, control the amount of slag remaining in the subsidized...

Embodiment 3

[0069] like figure 1 As shown, in this embodiment, a method for maintaining the eroded part of the furnace lining in the trunnion area of the converter and a method for using it after maintenance, specifically:

[0070] (1) 1 furnace of steel before tiling and maintenance, the steel tapping is completed, and the steel tapping volume is 68.6t. Use a laser thickness gauge to measure the lining thickness of the converter feeding side and the left and right trunnion areas. The measured lining thicknesses of the converter feeding side, left trunnion area and right trunnion area are respectively: 429mm, 418mm and 405mm, that is, the standard value of 650mm for the new lining In comparison, 221mm, 232mm and 245mm were eaten respectively.

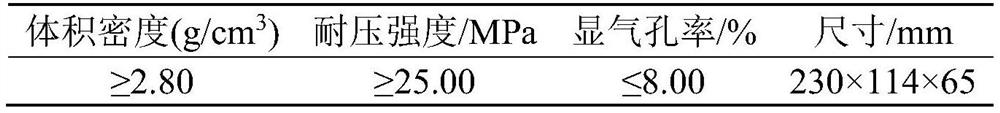

[0071] (2) Add 4.5t of clean bar scrap steel into the slag replenishment hopper, control the amount of slag remaining in the subsidized furnace converter at 5.4t, prepare 30 repair bricks, and the weight of repair bricks is 10kg / block.

[0072]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com