Liquid metal phase change microcapsule and preparation method thereof

A technology of liquid metal phase and liquid metal, which is applied in the field of liquid metal phase change microcapsules and its preparation, can solve the problems of small melting enthalpy, low heat exchange rate of microcapsules, and low thermal conductivity, so as to achieve stable melting point and prevent liquid state Metal leakage, the effect of simple operation of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

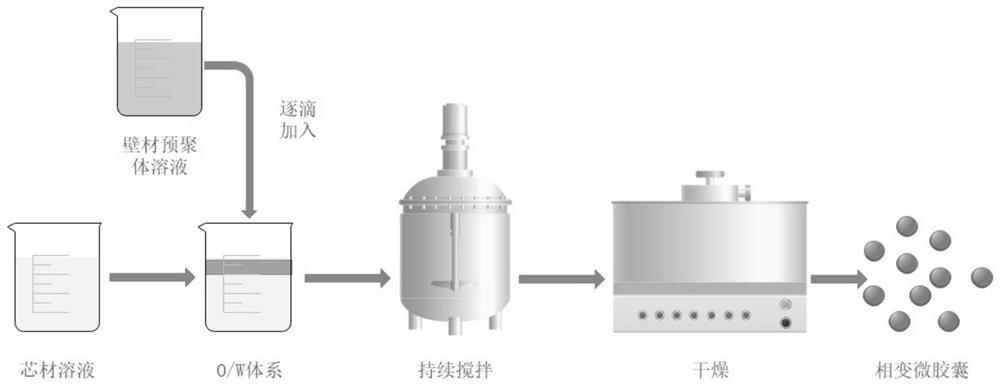

Method used

Image

Examples

preparation example Construction

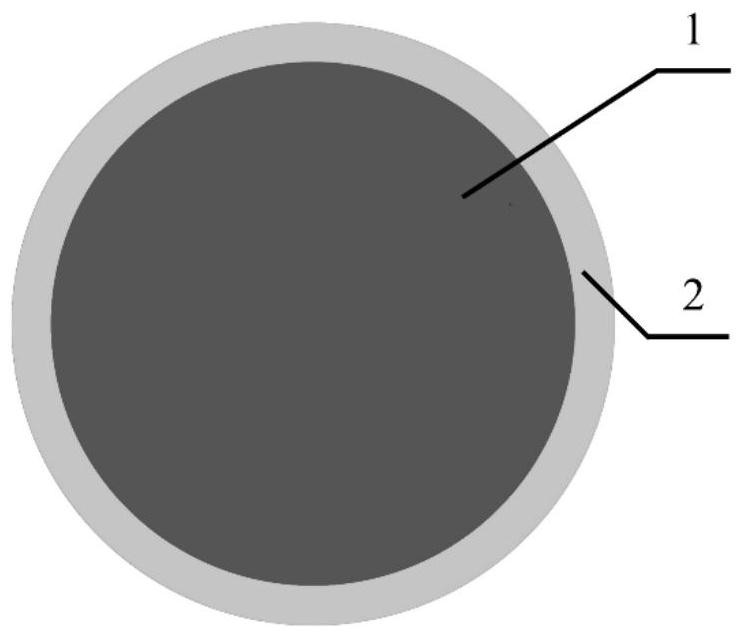

[0086] like figure 1 Shown is the liquid metal phase change microcapsule prepared by the preparation method of the present invention, the microcapsule is the obtained structure prepared by adopting the sol-gel method, using the liquid metal as the core material and the non-metal oxide as the wall material, including: A phase transition core 1 and a casing 2 surrounding the phase transition core, the phase transition core is a liquid metal core, and the casing is a non-metal oxide layer; the liquid metal is bismuth indium tin alloy, bismuth indium alloy or gallium Indium-tin alloy; the non-metal oxide is silicon dioxide or titanium dioxide.

[0087] A PVP non-metallic layer can also be arranged between the phase transition core and the outer shell, wherein the PVP non-metallic layer is arranged around the liquid metal core, and the non-metal oxide layer is arranged around the PVP non-metallic layer.

[0088] like Image 6 Shown is the DSC curve of the liquid metal phase chang...

Embodiment 1

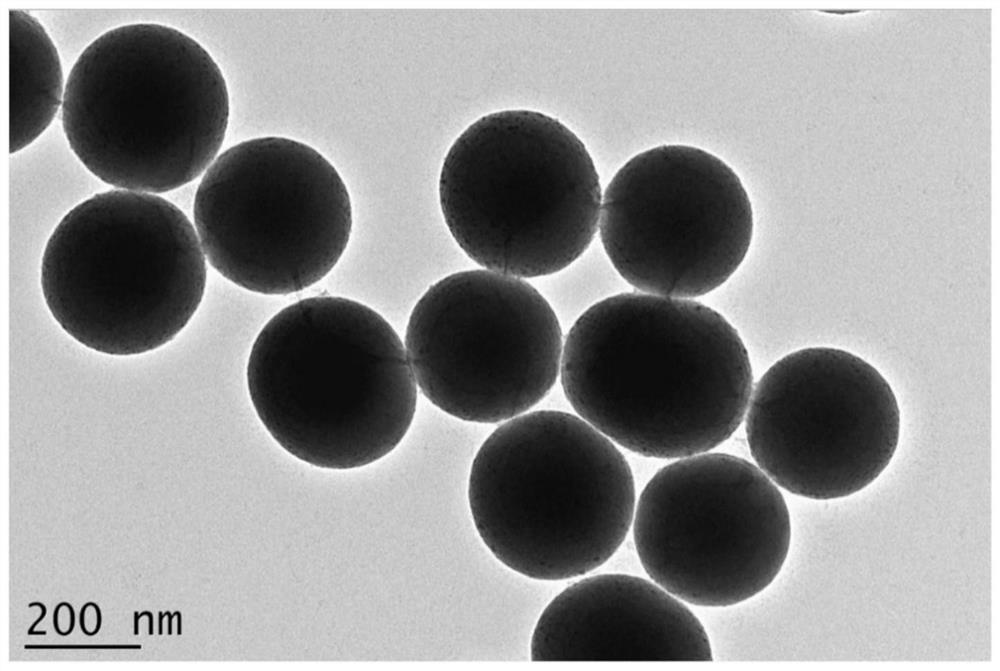

[0090] This example provides an inorganic non-metallic shell liquid metal phase change microcapsule, the structure of which includes a gallium indium tin liquid metal core and a silicon dioxide non-metallic layer, wherein the silicon dioxide non-metallic layer surrounds the gallium indium tin liquid metal core setup, its corresponding TEM image as image 3 shown. The specific preparation steps include:

[0091] S1. Preparation of core material solution: Select gallium indium tin alloy as the core material, mix 10 g of the core material with 25 ml of ethylene glycol, and use a homogenizer to homogenize to obtain a uniform solution of gallium indium tin liquid metal core. Mix 0.8 g of sodium dodecyl sulfate (SDS) solution (5% by mass) with the above homogeneous solution, and place it in a magnetic stirrer to stir at 300 rpm for 20 minutes, and then place it again. Ultrasonic dispersion in an ultrasonic cleaner for 20 minutes. A gallium indium tin core material solution is obt...

Embodiment 2

[0096] This embodiment provides another inorganic non-metallic shell liquid metal phase change microcapsule, the structure of which includes a bismuth indium tin metal core and a silicon dioxide non-metallic layer, wherein the silicon dioxide non-metallic layer surrounds the bismuth indium tin metal core , and its corresponding SEM image as Figure 4 As shown, the specific preparation steps include:

[0097] S1. Preparation of core material solution: prepare 10 g of bismuth indium tin alloy microspheres, put them in 3wt% APTMS-ethanol solution, and add 300 rpm magnetic stirring at room temperature for 24 hours. The bismuth indium tin alloy microspheres treated with APTMS-ethanol solution The ball was placed in a 40°C oven for drying, taken out, put into 25ml of deionized water, added a water bath, maintained at a constant temperature of 40°C, weighed 0.2g of sodium dodecyl sulfate (SDS) solution, and then used a magnetic stirrer. Stir at 300 rpm for 20 minutes, and then place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com