Material belt and film separation equipment of chip mounter feeder and application of material belt and film separation equipment

A technology of feeder and placement machine, which is applied to the unsealing, packaging, cutting and unsealing of objects, etc. It can solve the problems of wasting more electronic components, occupying a large area, and extending the leader film when the tape is separated, so as to ensure communication Real-time, low cost, and the effect of avoiding electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

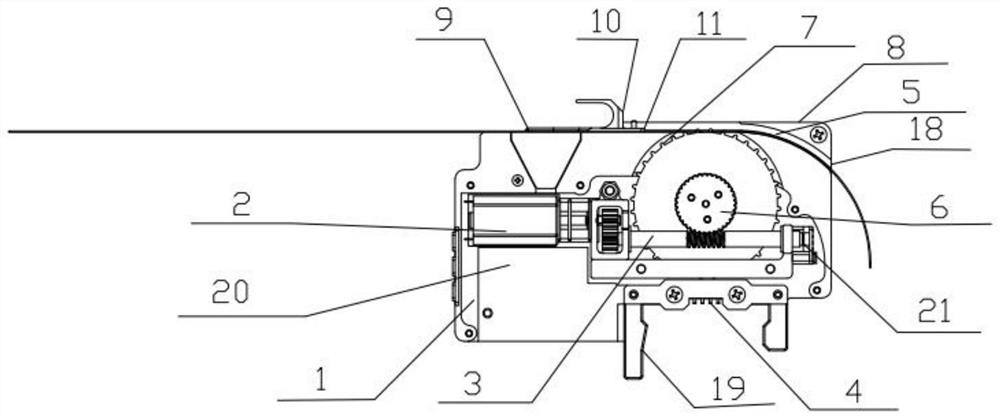

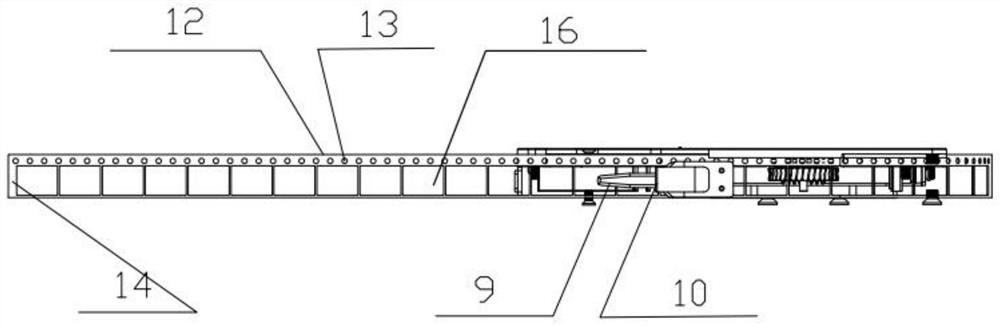

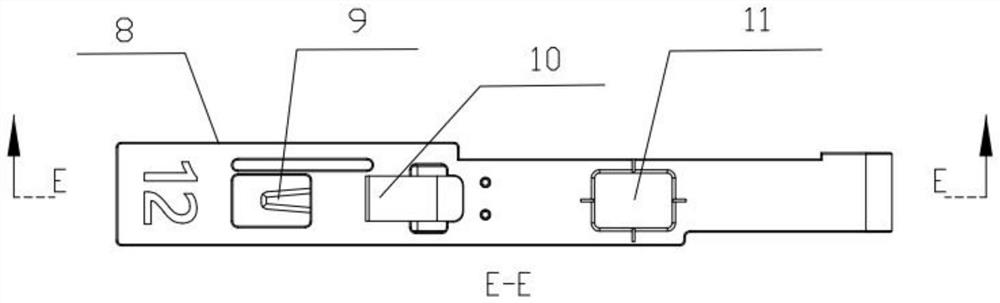

[0036] like figure 1 , Figure 8As shown, when in use, when the length of the braid is greater than 10cm, the braid 12 enters the guide rail 5 from the feeding port 17, starts the power mechanism 2, the driving tooth 7 on the driving wheel 6 and the braid on the braid 12. The hole 13 is engaged, the power mechanism 2 drives the drive wheel 6 to rotate through the transmission shaft, and at the same time, the drive tooth 7 drives the braid hole 13 to move forward, thereby driving the braid 12 to move into the guide rail 5, through the film pressing plate 15 and the cutting tool. Under the action of 9, the material film 16 is cut, and the cut fully enclosed film 16 is guided by the material tape film return guide 10, so that the braid 12 exposes the electronic components; Suck it away and stick it on the PCB. At this time, the fully enclosed film 16 is turned backward along the tape film return guide 10, and the braid 12 is discharged out of the feeder through the discharge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com