Pressing machine for latticed reinforcing ribs of paperboard

A rib and grid-like technology, which is applied in the field of grid-like rib presses, can solve the problems of slow pressing speed and achieve the effect of fast pressing speed and good compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

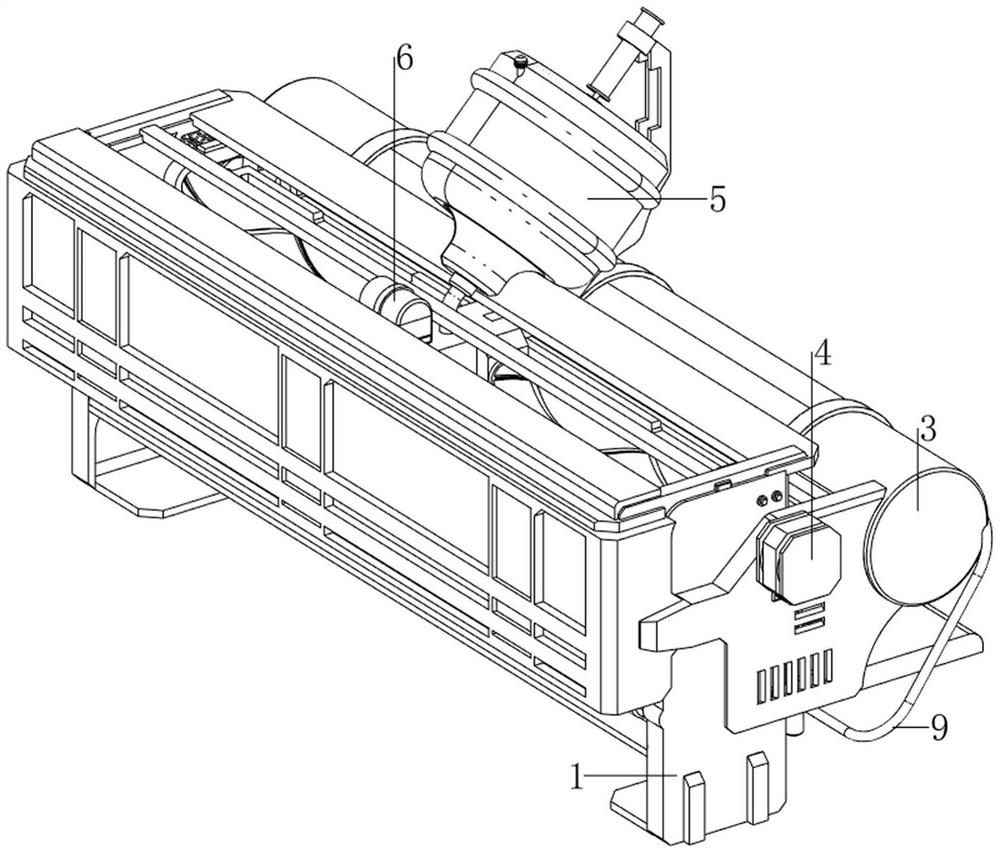

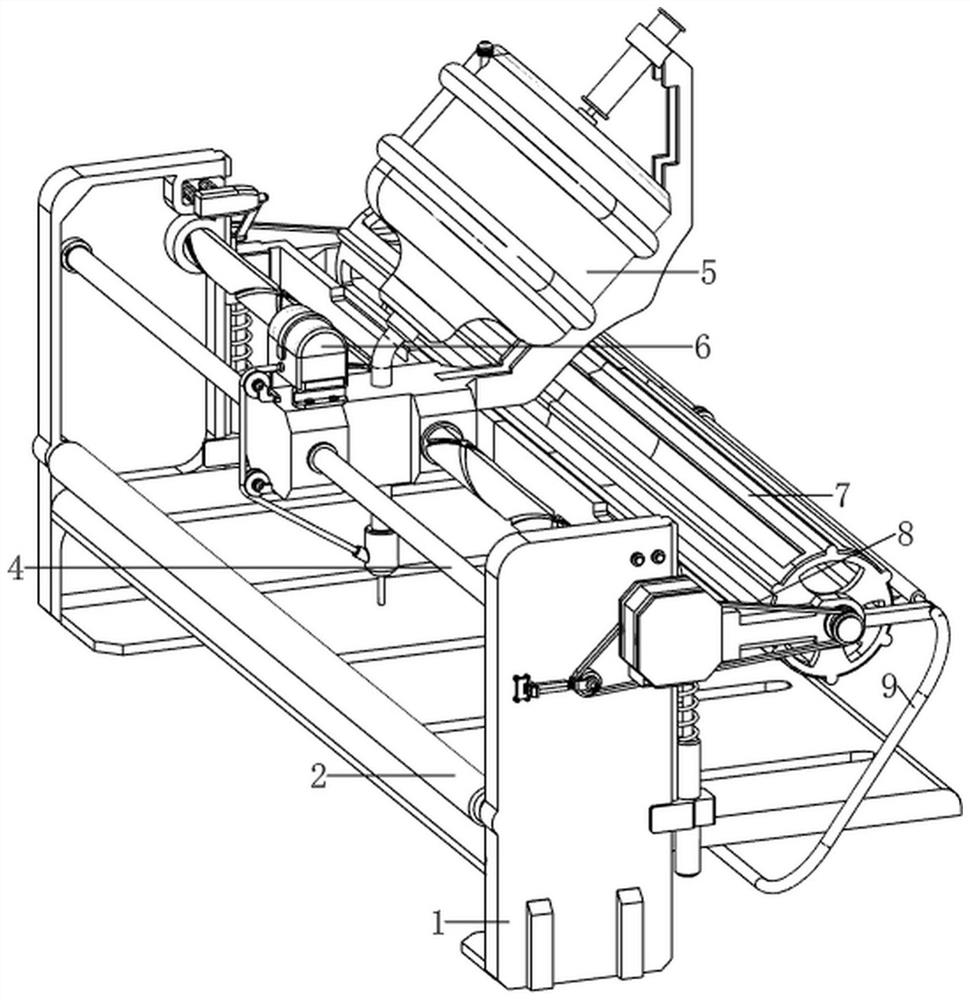

[0076] A grid-like reinforcing rib press for cardboard, reference now Figure 1-2 , including a bracket 1, a limit wheel 2, a protective casing 3, a moving mechanism 4, a gluing mechanism 5 and a compaction mechanism 7, a limit wheel 2 is rotated on the lower left side of the bracket 1, and the upper side of the bracket 1 is welded There is a protective casing 3 , a moving mechanism 4 is connected between the protective casing 3 and the bracket 1 , the moving mechanism 4 is provided with a gluing mechanism 5 , and the bracket 1 is provided with a compacting mechanism 7 .

[0077] Reference now figure 1 and image 3 , the moving mechanism 4 includes a motor frame 41, a servo motor 42, a twist rod 43, a guide rod 44 and a first moving frame 45, the front side of the protective casing 3 is connected to the upper side of the motor frame 41, and the inner side of the motor frame 41 is fixed by bolts There is a servo motor 42, the output shaft of the servo motor 42 is connected wi...

Embodiment 2

[0084] On the basis of Example 1, now refer to figure 1 , figure 2 and Figure 7 , also includes a thread-embedding mechanism 6, the thread-embedding mechanism 6 includes a cable box 61, a first guide wheel 62, a first fixed frame 63 and a fiber line 64, and the upper, front, rear, and left sides of the first movable frame 45 are fixed by bolts. A first fixed frame 63 is connected, a wire box 61 is arranged between the two first fixed frames 63, a through hole 65 is opened on the lower side of the left part of the wire box 61, and the upper and lower sides of the first movable frame 45 are rotatably provided on the left side. In the first guide wheel 62, the fiber line 64 is placed in the wire box 61. The fiber line 64 passes through the wire box 61 and goes around the left side of the two first guide wheels 62 in turn to connect with the nozzle 53.

[0085] Reference now figure 2 , Figure 12 , Figure 13 and Figure 14 , also includes a rotating mechanism 8, the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com