An energy-saving four-cylinder indirect thermoforming hydraulic press control system

A technology of control system and hydraulic press, which is applied in the field of hydraulic press control system and thermoforming hydraulic press control system. It can solve the problems of slow pressure gradient process, affecting the tensile quality of workpieces, and large heat loss of workpieces in air cooling, so as to achieve precise control of pressure and speed. , Shorten the pressure process, reduce the effect of air-cooled heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

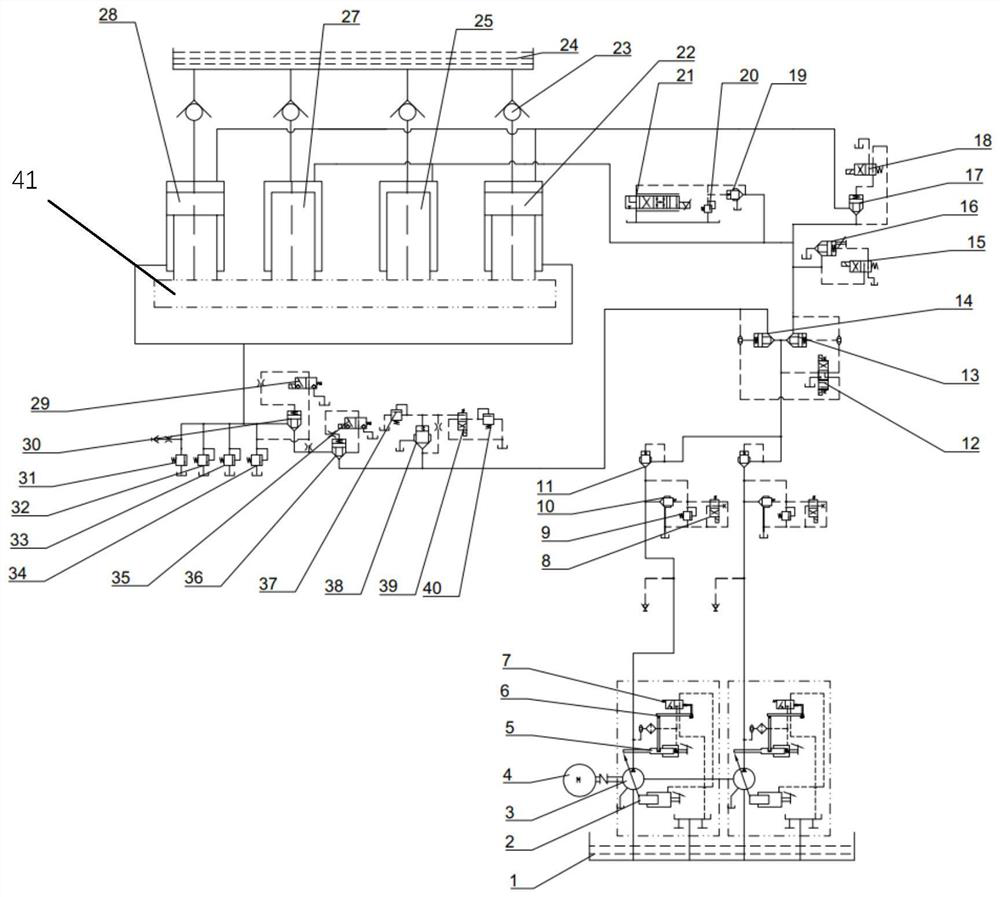

[0040] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

[0041] Such as figure 1 As shown, the present invention includes a plurality of pump direct drive state pressure control units, a plurality of multi-pump confluence control units, a cylinder direction switching unit, a suppression level control unit, a return control unit, a relief valve parallel control unit and a four-column press cylinder unit ;

[0042] Multiple pump direct drive state pressure control units are respectively connected with multiple multi-pump confluence control units, the oil outflow of multiple multi-pump confluence control units is merged into one oil circuit and then communicated with the oil cylinder direction switching unit, and the oil cylinder direction switching unit is respectively connected with The process main oil circuit is connected with the return main oil circuit, and the process main oil circuit is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com