Machining device for gearbox of electric vehicle

A processing device and gearbox technology, which is applied in metal processing equipment, used abrasive processing devices, manufacturing tools, etc., can solve the problems of unsatisfactory cleaning and treatment of waste gearboxes and affecting the processing effect of waste gearboxes, etc. Achieve the effect of improving cleaning processing effect, improving processing efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

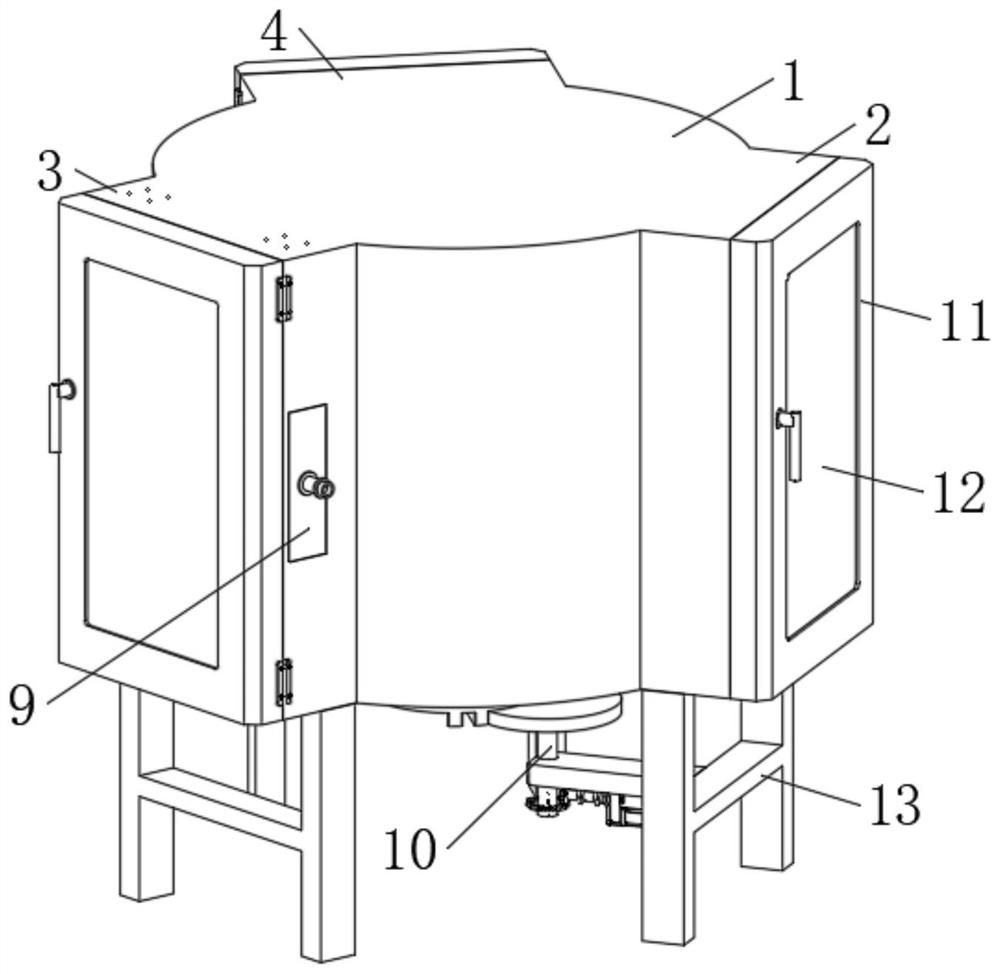

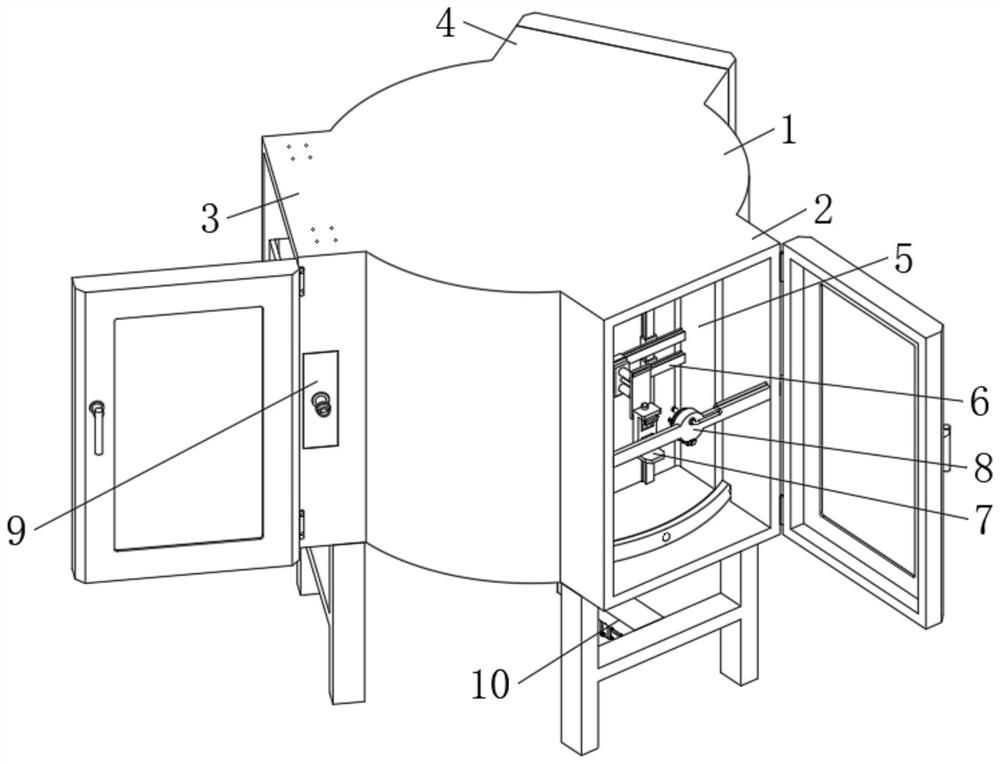

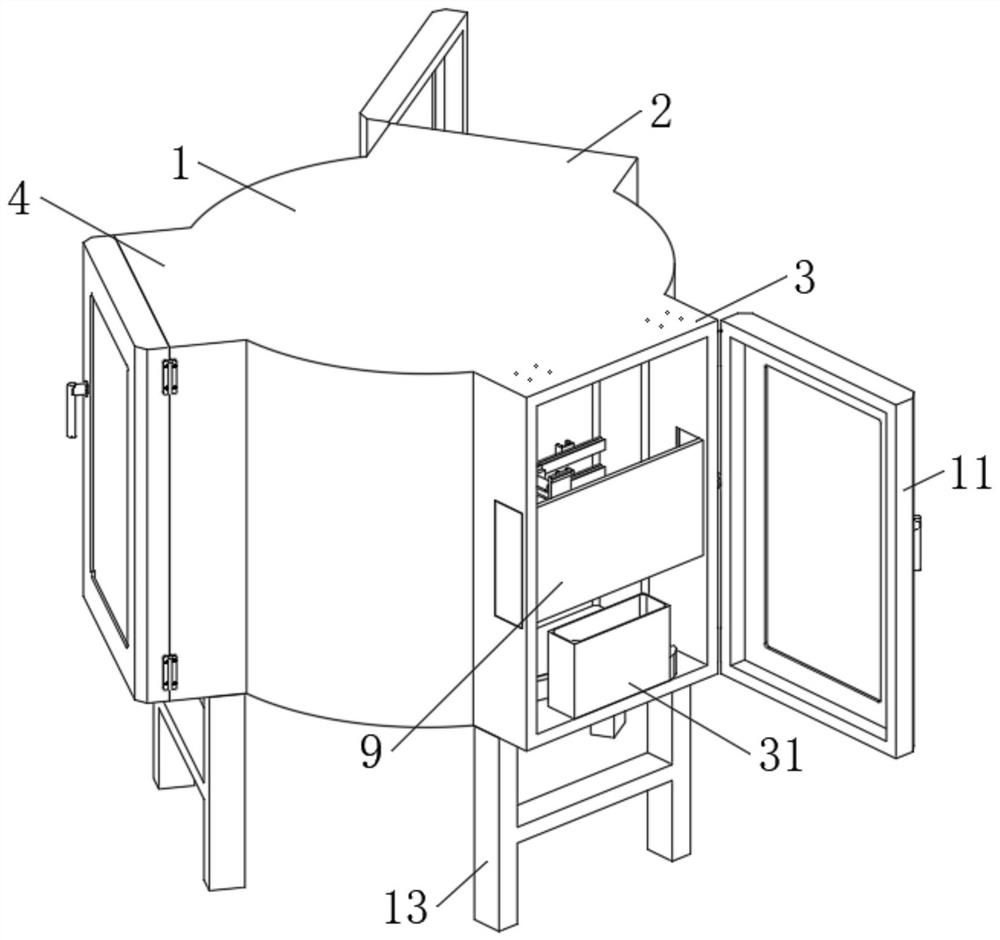

[0033] Example: as Figure 1-11As shown, the present invention provides an electric vehicle gearbox processing device, including a device outer frame 1, and the outer side of the device outer frame 1 is integrally formed with a first chamber 2, a second chamber 3 and a third chamber 4. The first chamber 2 , The second warehouse 3 and the third warehouse 4 have the same structure and are distributed in a circular array. A conversion table 5 is provided in the outer frame 1 of the device, and an adjustment assembly 6 is provided on the conversion table 5. The cleaning component 8, the middle part of the second warehouse 3 is fixedly clamped with a drying component 9, the bottom end of the outer frame 1 of the device is provided with a driving component 10 used in conjunction with the conversion table 5, the first warehouse 2, the second warehouse 3 and the first A sealing door frame 11 is installed on the side of the three warehouses 4 away from the outer frame 1 of the device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com