Wastewater treatment system for bypass sludge discharge

A wastewater treatment system and sludge technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, adsorbed water/sewage treatment, etc., can solve the problem that the adsorption effect of activated sludge is not utilized, and reach the surface The effect of load reduction, reduction of sludge volume and improvement of sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

Specific examples:

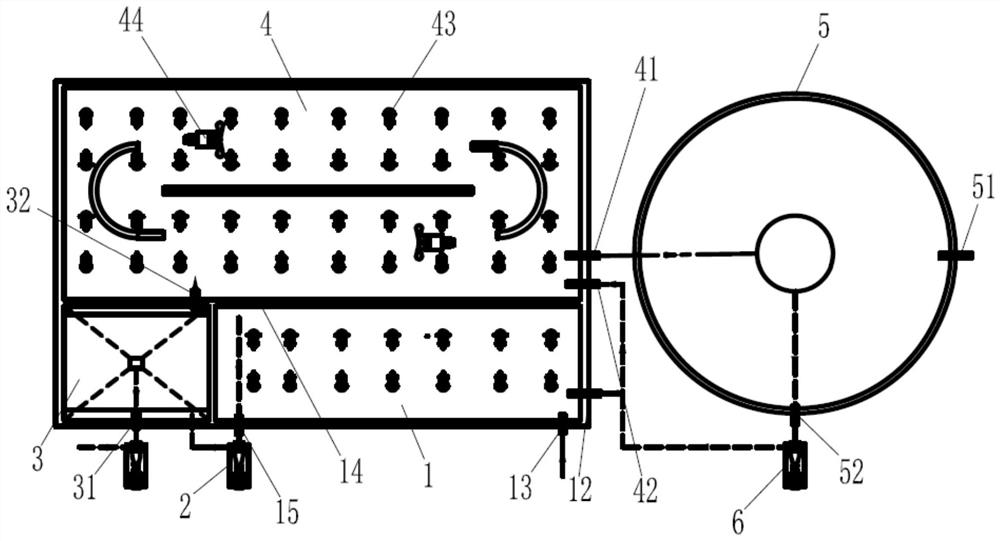

[0026] In this embodiment, the mud-water separator adopts a combination of plate and frame filter press after sedimentation. refer to figure 1 : A printing and dyeing enterprise in Hebei, the wastewater volume is 1500m3 / day, the wastewater COD is 1500~2000mg / L, and the wastewater COD after pretreatment is 1000~1200mg / L. After the pretreatment, the waste water is subjected to subsequent aerobic biochemical treatment through the wastewater aerobic treatment process and system of the bypass sludge discharge BSDP of the present invention. The adsorption reaction tank 1 is 14 meters long, 4.5 meters wide, and 5.0 meters deep; the delayed aeration tank 4 is 20 meters long, 8.5 meters wide, and 5.0 meters deep; the sludge discharge sedimentation tank 3 is 20 meters long, 8.5 meters wide, and deep 5.5 meters; the reflux sedimentation tank 5 adopts a radial flow sedimentation tank with a diameter of 12 meters and a depth of 4.5 meters; the sludge return pump 6 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com