A battery production and assembly system for new energy vehicles

A new energy vehicle, production and assembly technology, applied in the direction of assembling battery machine, secondary battery manufacturing, final product manufacturing, etc., can solve the problems of battery detachment, complicated operation, hidden safety hazards, etc., and achieves low electrical resistance and electrical conductivity. Good, close contact effect of external stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purposes, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments will be clearly and completely described below with reference to the drawings in the embodiments of the present invention, and the following embodiments are used to illustrate the present invention .

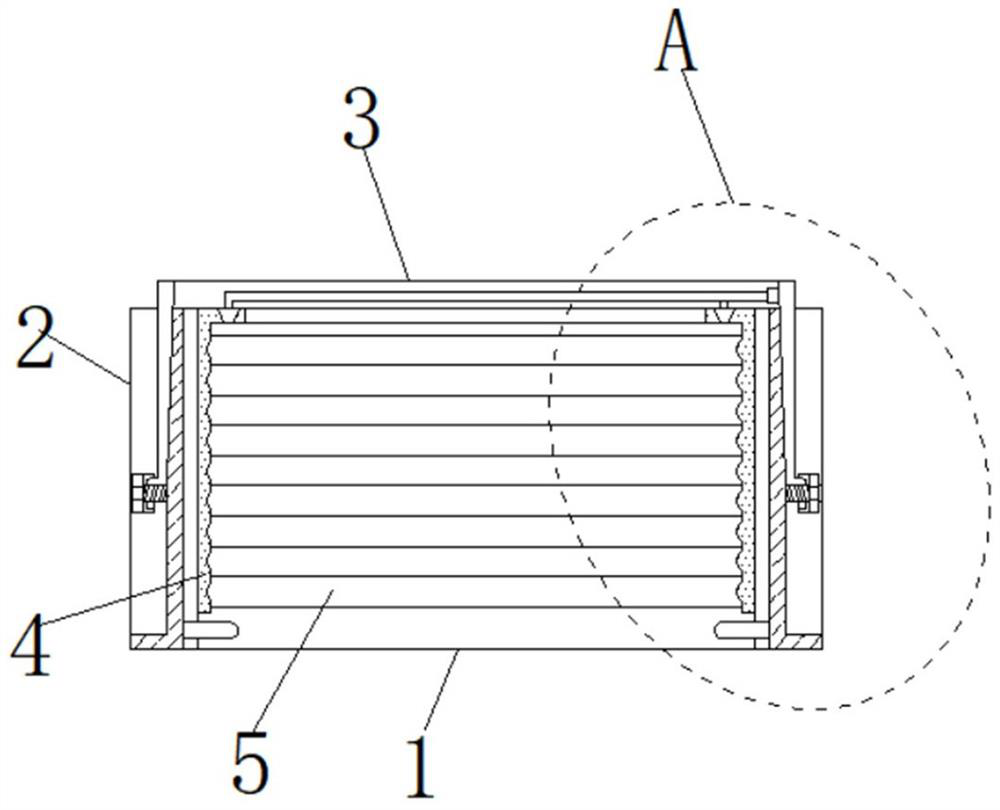

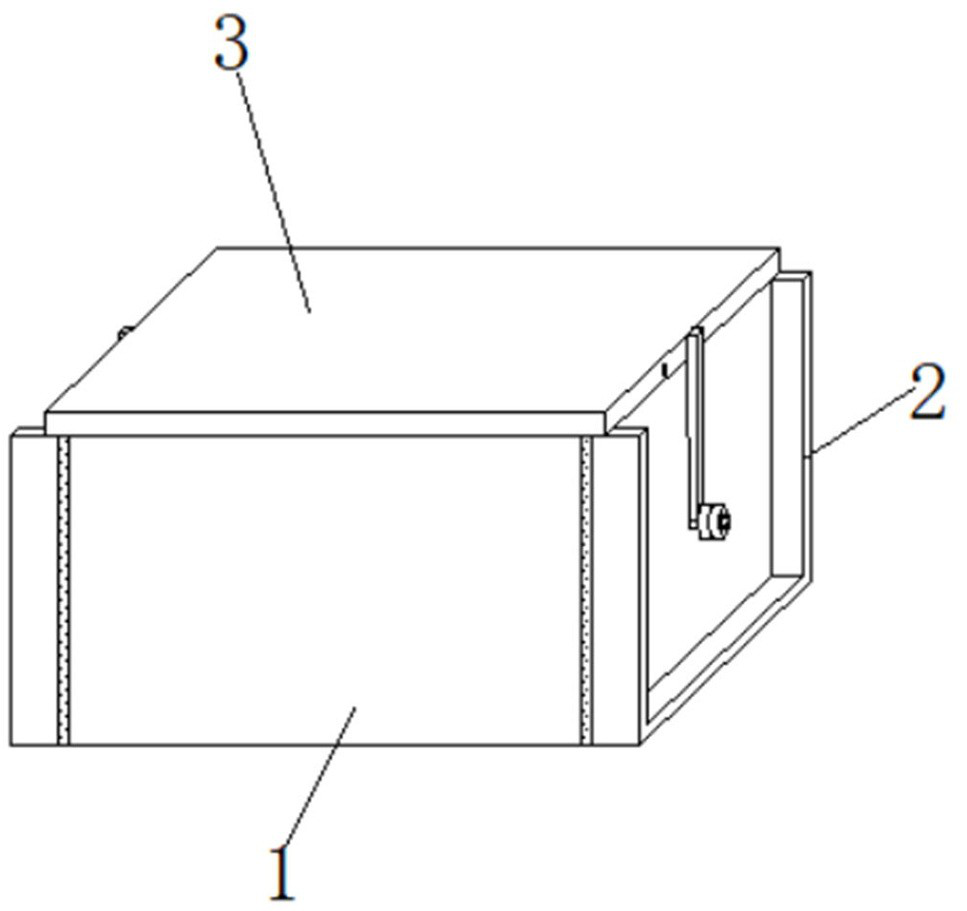

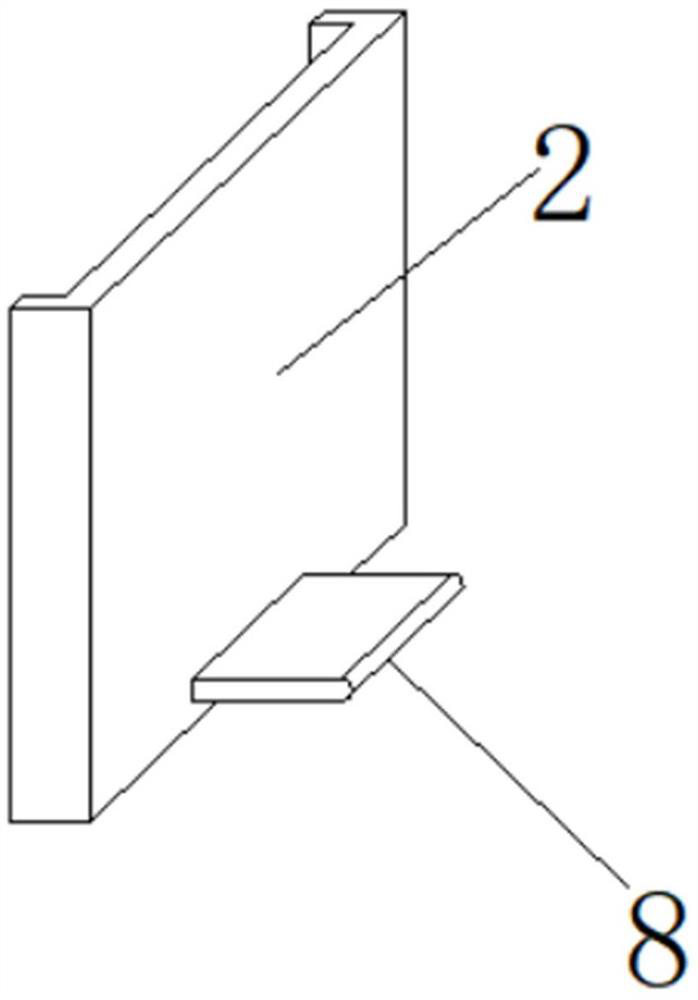

[0025] like Figure 1 to Figure 3 As shown in the figure, a battery production and assembly system for a new energy vehicle includes a battery box 1, a splint 2 is provided on both sides of the battery box 1, a top cover 3 is located on the upper part of the battery box 1, and the middle of both sides of the top cover 3 is provided There are extruding rods 12 , and threaded screw rods 10 are fixed in the middle of the opposite sides of the two splints 2 .

[0026] like Figure 1 to Figure 6 As shown, in the specific embodiment, the lower part of the opposite side of the two splints 2 is vertically fixed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com