Cells for wound lithium batteries and wound lithium batteries

A lithium battery, wound-type technology, applied in the direction of alkaline battery electrodes, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of complex assembly operations, poor heat dissipation performance of batteries and high-rate discharge performance, and achieve easy installation , high yield and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

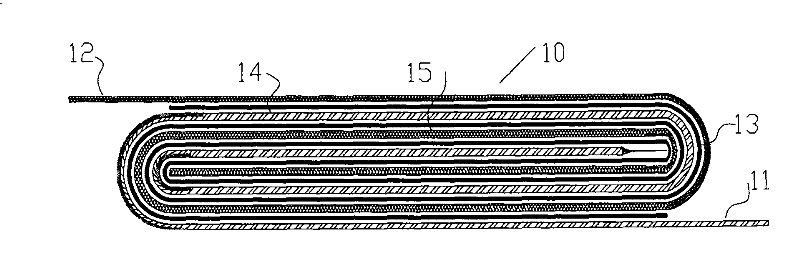

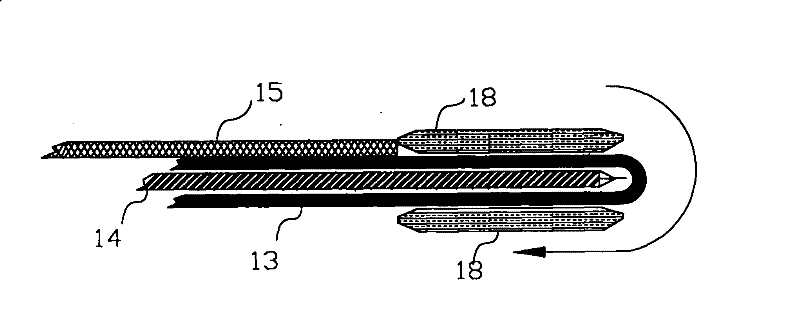

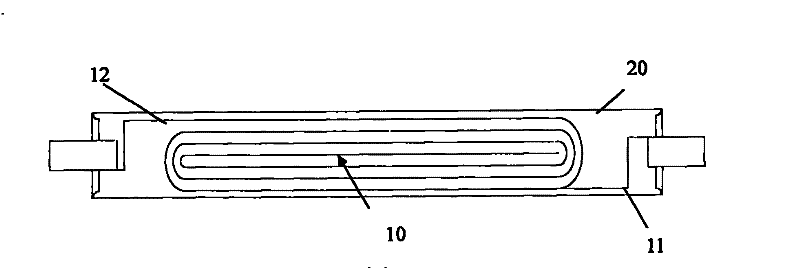

[0020] figure 1 Shown is the structure of the cell according to the present invention. The cell 10 includes a positive electrode sheet 14 , a negative electrode sheet 15 , a separator 13 , a positive electrode tab 11 and a negative electrode tab 12 . Wherein, both the pole piece and the separator are strip-shaped, and the positive and negative electrode pieces are formed by coating the positive and negative current collectors with polar dressings. , Negative electrode sheets are wound together to form the battery core, the tab is connected to the end of the winding of the pole sheet, and the tab is the part of the end of the current collector that is not coated with a polar coating, that is, the current collector Therefore, the lug is a current collector lug, which is integrated with the pole piece. Specifically, the winding end of the positive electrode sheet 14 integrally forms a positive electrode ear 11, and the winding end of the negative electrode sheet 15 integrally fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com