Crack defect quantification method and device based on magnetic flux leakage space integration

A space integration and defect technology, applied in the direction of material magnetic variables, etc., can solve the problems of crack magnetic flux leakage signal leakage and loss of effective signal, etc., and achieve the effect of high quantification efficiency, clear theoretical model, and simple calculation formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

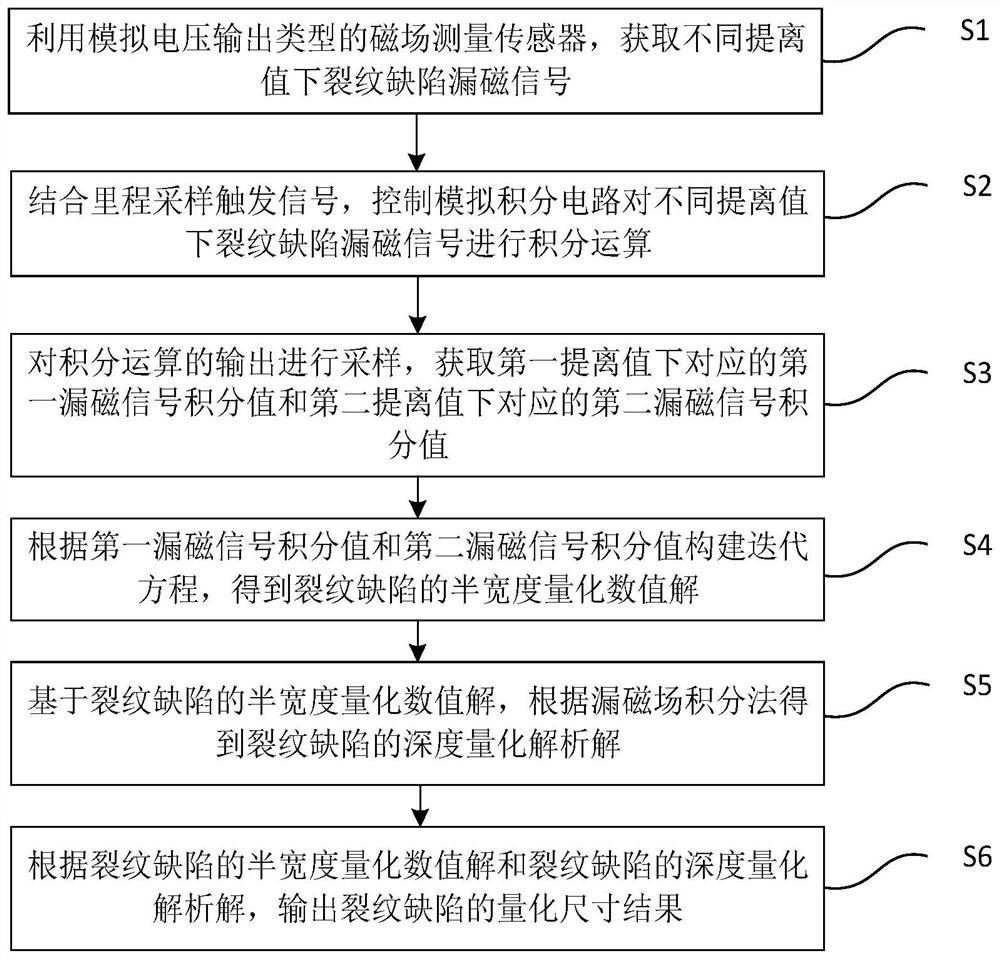

[0042] figure 1 It is a flow chart of a crack defect quantification method based on magnetic flux leakage spatial integration according to an embodiment of the present invention.

[0043] like figure 1 As shown, the method includes but is not limited to the following steps:

[0044] In step S1, the magnetic field measurement sensor of the analog voltage output type is used to obtain the magnetic flux leakage signal of the crack defect under different lift-off values.

[0045] Specifically, in this embodiment, the magnetic field measurement sensor of the analog voltage output type is used to obtain the magnetic flux leakage signal of the crack defect under different lift-off values; Under the lift-off value, the magnetic leakage signal of crack defect is the horizontal component B of the leakage magnetic field x , where the horizontal direction is the magnetization direction of the measured material; the vertical direction is the direction perpendicular to the magnetization,...

Embodiment 2

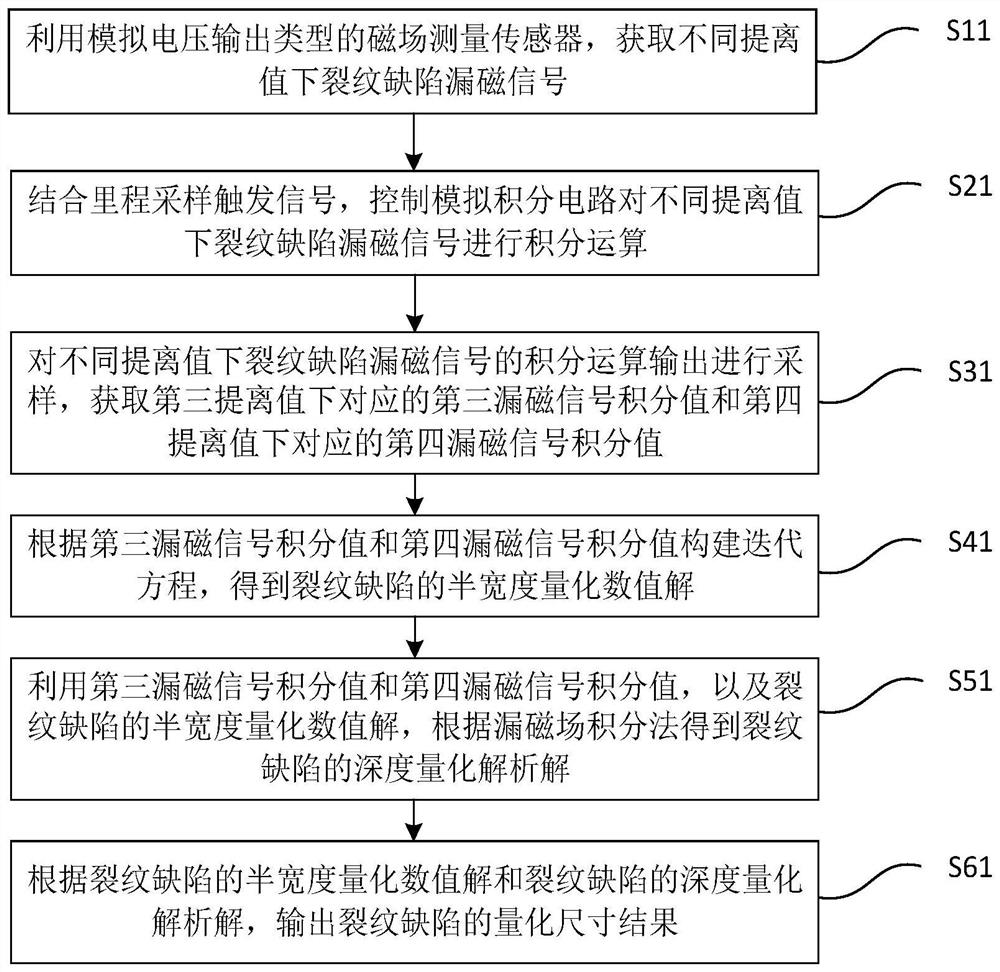

[0070] figure 2 is a flowchart according to a second embodiment of the present invention.

[0071] like figure 2 As shown, the crack defect quantification method based on the spatial integration of magnetic flux leakage provided in this embodiment includes but is not limited to the following steps:

[0072] In step S11, a magnetic field measurement sensor of an analog voltage output type is used to obtain the magnetic flux leakage signal of the crack defect under different lift-off values.

[0073] Step S21, combined with the mileage sampling trigger signal, the analog integration circuit is controlled to perform integration operation on the magnetic flux leakage signal of the crack defect under different lift-off values.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com