Integrated assembly unit for accessories of refrigeration equipment for cold chain

A refrigeration equipment, integrated technology, applied in the direction of welding equipment, metal processing equipment, gas flame welding equipment, etc., can solve the problems of copper tube thermal deformation, cumbersome assembly process, copper tube wear, etc., to avoid copper tube deformation, ensure The effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

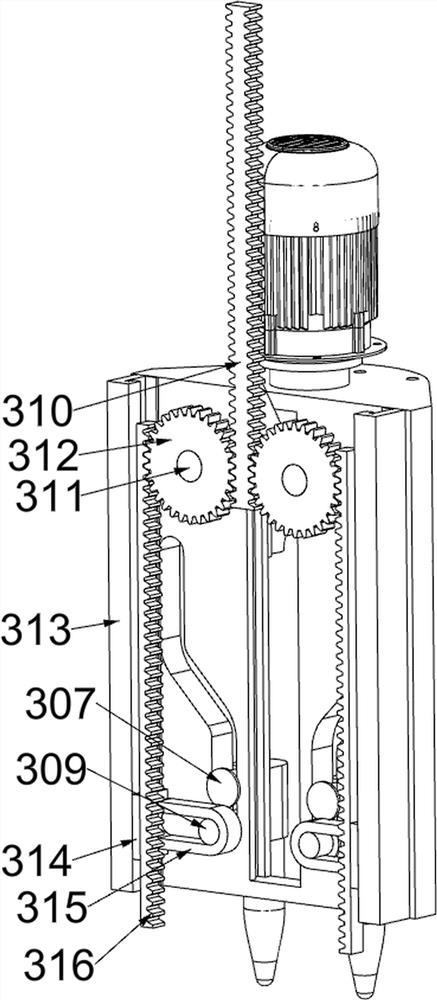

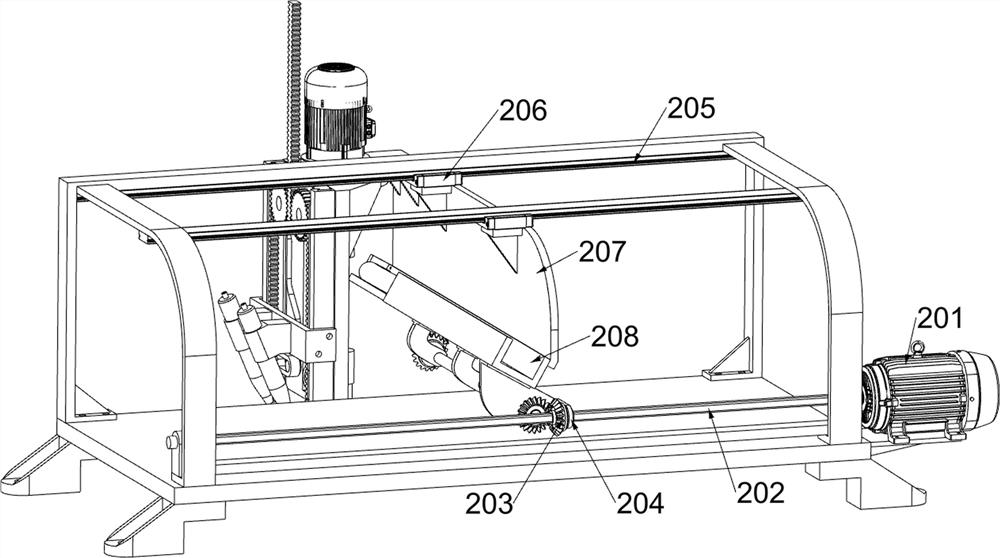

[0032] An integrated assembly unit of refrigeration equipment accessories for cold chain, such as Figure 1-10 As shown, it includes a mounting seat 1, a fixing plate 2, a supporting frame 3, a supporting folding plate 4, an automatic feeding unit and a flare welding unit; the mounting seat 1 is provided with four, and the upper sides of the four mounting seats 1 are fixed together A fixed plate 2 is connected; a support frame 3 is fixedly connected to the upper front part of the fixed plate 2; ; The upper rear of the fixed plate 2 is connected with an automatic feeding unit; the automatic feeding unit is connected with the support frame 3; the automatic feeding unit is connected with the support folding plate 4; the automatic feeding unit is connected with a flare welding unit.

Embodiment 2

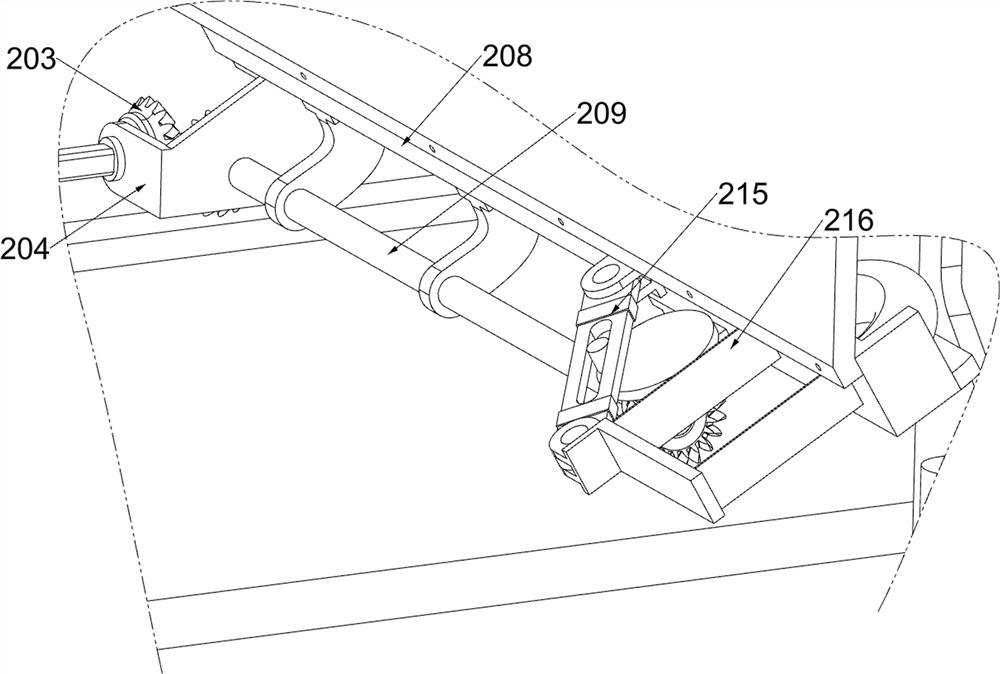

[0034] On the basis of Example 1, as Figure 1-10As shown, the automatic feeding unit includes a first motor 201, a spline shaft 202, a first bevel gear 203, a connecting frame 204, a first electric sliding rail 205, a first electric sliding block 206, a mounting plate 207, a U-shaped infeed The material rack 208, the first rotating shaft 209, the second bevel gear 210, the third bevel gear 211 and the feeding assembly; the upper rear part of the fixing plate 2 is bolted with the first motor 201; the upper rear part of the fixing plate 2 is rotated through the bracket A spline shaft 202 is connected; a first bevel gear 203 is fixedly connected to the shaft sleeve of the spline shaft 202; a first electric slide rail 205 is bolted on the inner and upper side of the support frame 3; Another first electric sliding rail 205 is connected with a common bolt; a first electric sliding block 206 is slidably connected to each of the two first electric sliding rails 205; a mounting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com