Method for producing battery cell

A battery cell, single cell technology, applied in the direction of manufacturing tools, secondary batteries, battery assembly machines, etc., to achieve the effects of increasing power, reducing ohmic heat loss, and increasing current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

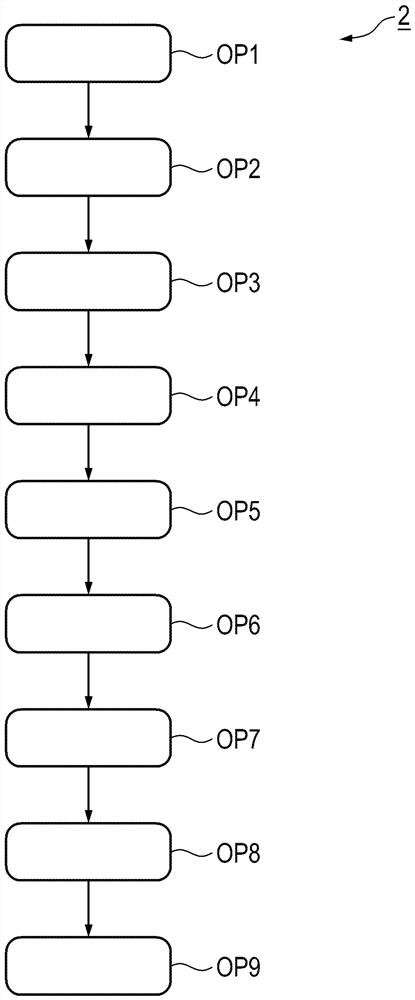

[0042] As an alternative to the method step OP1 described above, it is conceivable, for example, to clean the current conductors 8 , 10 by means of a plasma.

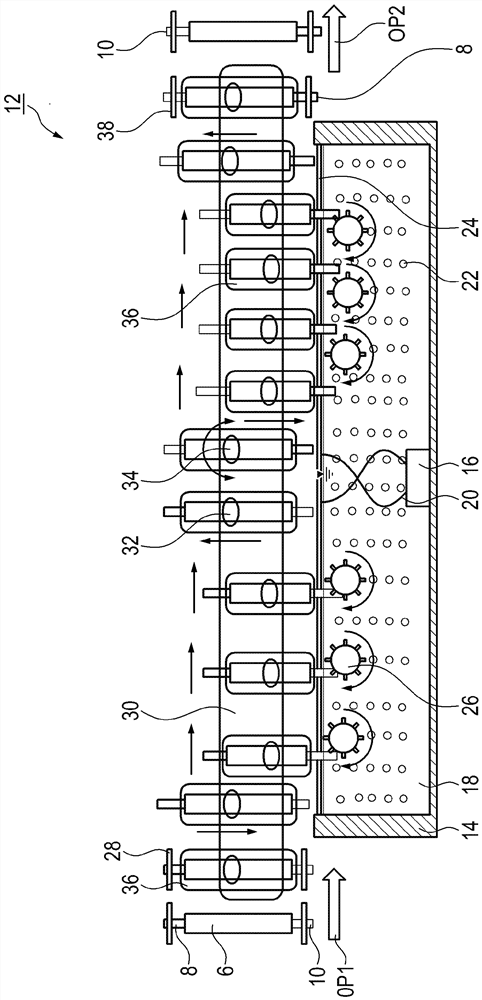

[0043] Once the surface has been cleaned, it is preheated in method step OP2 by induction or resistance heating under an inert nitrogen atmosphere ( Figure 4 ). For example, in the case of resistive heating, two energizable plungers are pressed onto the current conductors 8 , 10 . The plunger here is in particular made of graphite, titanium or tungsten.

[0044] In the case of the copper anode of the current conductor 10 , it is preheated, for example, up to 600° C. In the case of the aluminum cathode of the current conductor 8 , preheating is carried out up to 300° C., for example. For this purpose, the device has a heating chamber as housing 40 . The heating chamber 40 has a gas 42 inside it.

[0045] The inert gas 42 is designed as nitrogen, for example, and is introduced into the heating chamber 40 at an exces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com