Ultrasonic detector for pipeline flaw detection

An ultrasonic and detector technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., to achieve the effect of improving the effect, improving efficiency and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

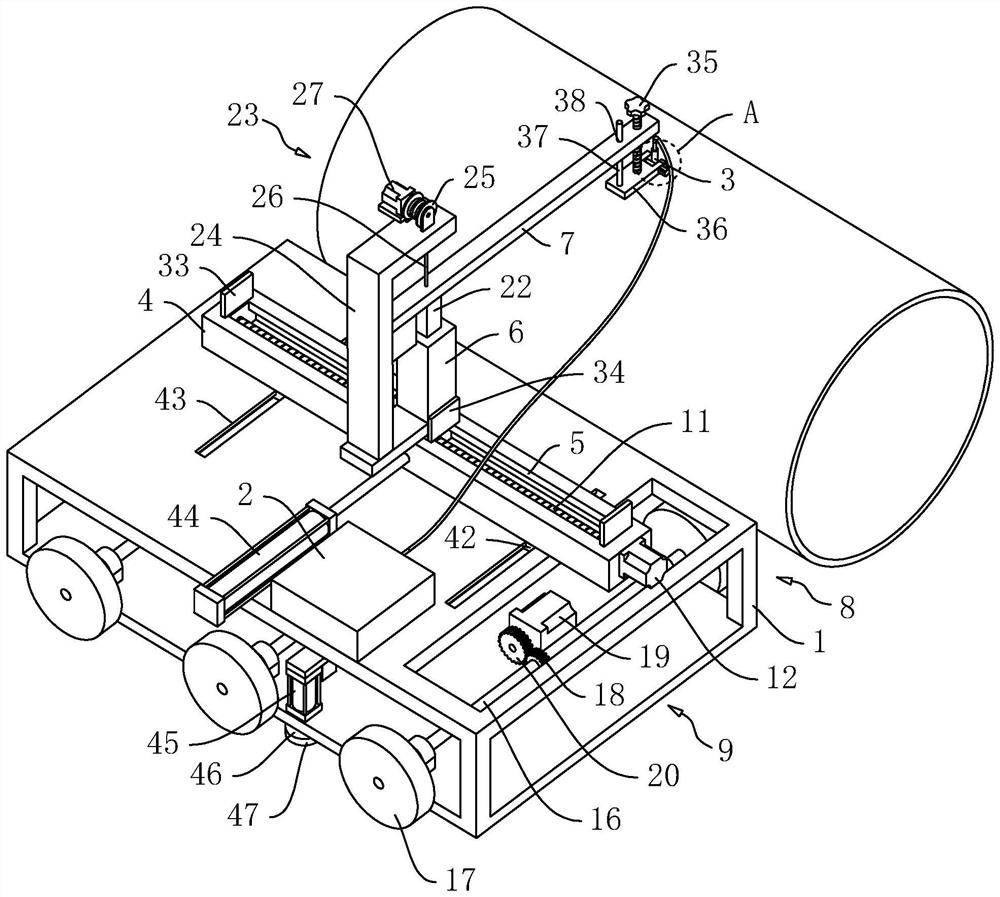

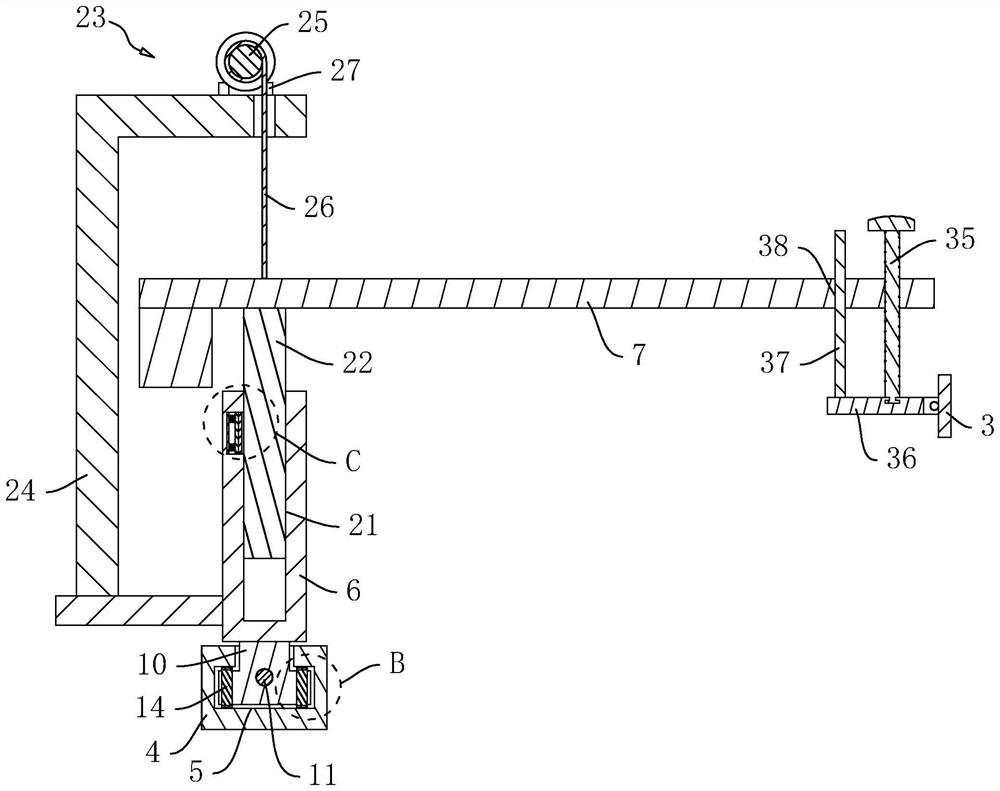

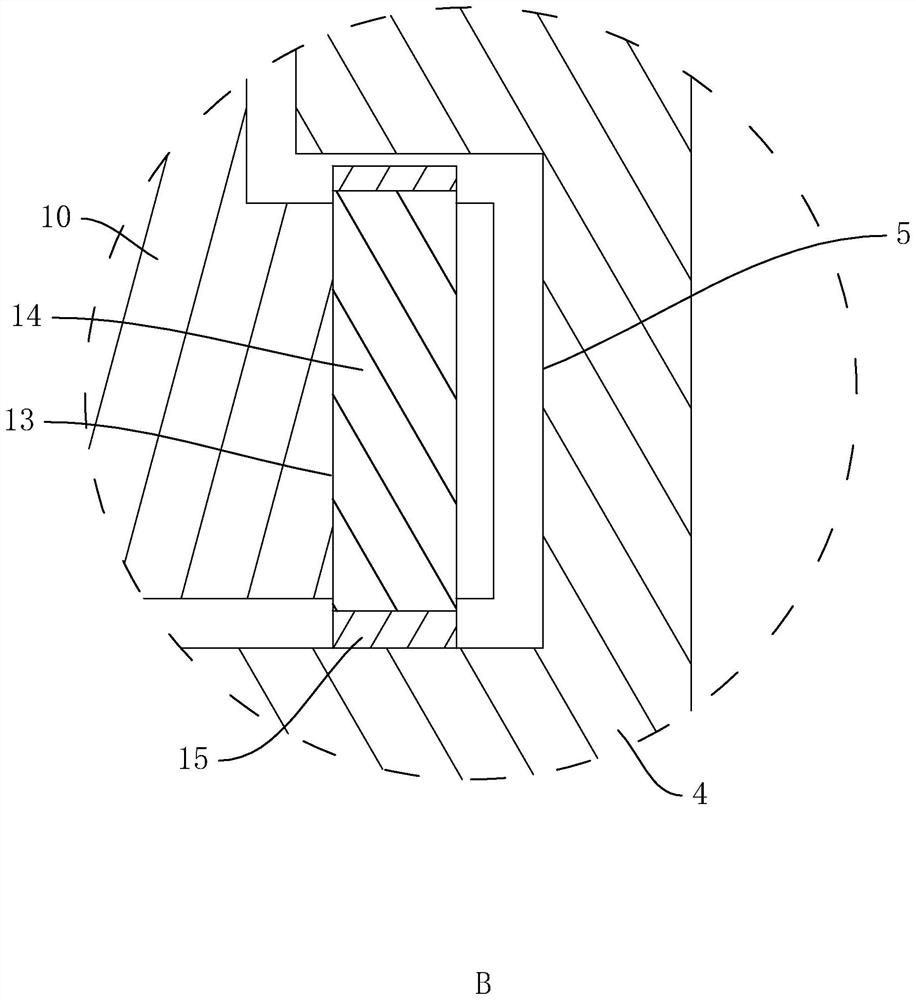

[0035] like figure 1 As shown, the ultrasonic detector for pipeline flaw detection includes a support frame 1 and a detection host 2 arranged on the support frame 1. The detection host 2 is connected with a detection head 3 through a detection line, and the support frame 1 is fixedly connected with a device along its own length. The fixed block 4, the fixed block 4 is provided with a T-shaped first chute 5 along its own length direction, the first chute 5 is slidingly connected with a detection block 6, and the detection block 6 is connected with an extension plate 7, and the detection head 3 is connected on the extension board 7.

[0036] like figure 1 As shown, a detection assembly 8 for driving the detection block 6 to slide along the first chute 5 and a drive assembly 9 for driving the support frame 1 to move are respectively provided on the support frame 1 . Therefore, when the pipeline needs to be detected, the staff can first move the support frame 1 to the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com