Biomass gas purifier and gasification purification device

A technology of biomass gas and purification device, which is applied in the direction of combustible gas purification, combustible gas purification/transformation, catalytic conversion gas purification of impurities, etc., to achieve the effect of reducing cost, reasonable and compact structure design, and solving difficult treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

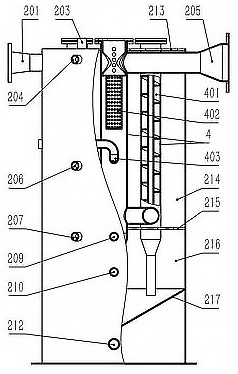

[0033] The upper part of the cooling chamber 214 is provided with a water replenishment port 204, the middle and lower part is provided with a cooling chamber liquid level port 206, and the top is equipped with a breathing valve 203; through the cooling chamber water replenishment port 204 and the cooling chamber liquid level port 206, an automatic water replenishment valve 202 can be installed to realize Automatic replenishment of cooling chamber 214.

[0034] The tar collection chamber 216 is located at the lower part of the purifier, and its lower part is in the shape of an inverted cone (the bottom plate is a conical plate 217, which is easy for liquid to flow out), and the end of the conical shape is a liquid outlet 212; during the working process, the gas is purified by the gas purification group 4 The resulting tar mixture will enter the tar collection chamber 216 through the bottom of the pipeline, and the tar mixture in the tar collection chamber 216 will liquid-seal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com