Wastewater treatment equipment for degrading metallic compounds

A metal compound and wastewater treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve high purification efficiency, increase available resources, and avoid secondary pollution

Inactive Publication Date: 2022-06-10

SHANDONG WEITIAN FINE CHEM TECH CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, in the existing wastewater treatment of metal compounds, flocculants are added to react with metal wastewater to produce flocculent precipitates. After a period of wastewater treatment, when the flocs reach The saturated state will affect the subsequent sewage treatment, which will lead to incomplete sewage treatment. This requires the equipment to be shut down to deal with the flocculent sediment after filtration, and then manually removed from the filter tank, which is a waste of time and the process is extremely cumbersome.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

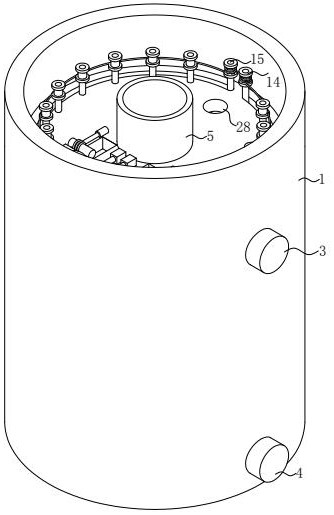

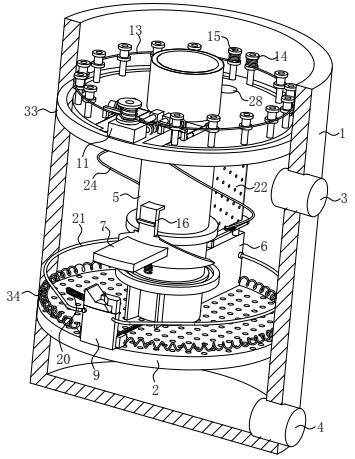

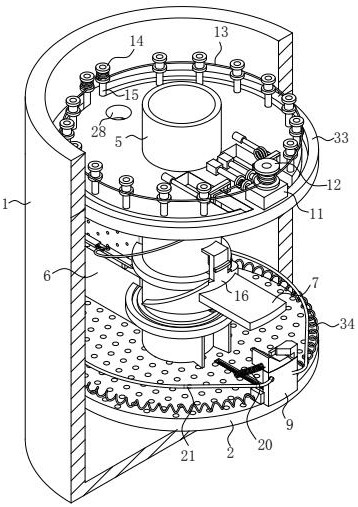

The invention discloses wastewater treatment equipment for degrading metallic compounds, which comprises a barrel, the lower end of the barrel is fixedly connected with a water leakage plate, the upper end of the barrel is fixedly connected with a water inlet end, the lower end of the barrel is fixedly connected with a water outlet end, and the interior of the barrel is fixedly connected with a discharge column. A material collecting assembly is arranged on the outer side of the discharging column, and a driving assembly is arranged on the material collecting assembly. Water is injected into the barrel through the water inlet end to react with a flocculating agent in the barrel to form flocculent precipitates, the conveying driving assembly can drive the conveying assembly to convey the precipitates sinking on the water leakage plate into the discharging column, and the flocculent precipitates in sewage can be conveyed to the outside of the barrel through the discharging column. The barrel can continuously treat sewage, flocculent precipitates do not need to be manually treated, and the sewage treatment efficiency is improved.

Description

technical field [0001] The invention relates to waste water treatment, in particular to waste water treatment equipment for degrading metal compounds. Background technique [0002] In industrial production, sewage containing metal ions is very common, and this sewage containing metal ions cannot be discharged directly to the outside, if it is discharged, it will cause serious pollution. Therefore, further treatment is required for such sewage containing metal ions Then it can be discharged or reused. At present, the sewage in industrial production mainly contains metal ions such as calcium, chromium, cadmium, nickel, copper, zinc, gold, silver, etc. The existing treatment method is to pass the sewage through a chemical reaction tank to react Finally, the precipitate of the metal ion compound is removed, and then the treated water is obtained. [0003] At present, in the existing wastewater treatment of metal compounds, flocculants are added to react with metal wastewater to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F9/04C02F1/00C02F1/52

CPCC02F1/001C02F1/5281C02F2303/14

Inventor 刘玉强刘玉真刘乾李章波

Owner SHANDONG WEITIAN FINE CHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com