Plate forming device for fire exit door

A sheet metal forming and fire door technology, which is applied in the direction of grinding driving device, grinding slide plate, grinding machine tool parts, etc., can solve the scratches of staff and users, reduce the promotion and use of equipment, and reduce the quality of fire door forming and other problems to achieve the effect of reducing scratches, improving grinding quality and improving safety

Inactive Publication Date: 2022-06-10

江苏久泰消防设备有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the production process of fire doors, it is necessary to stamp the plates with holes of different sizes and shapes, and then carry out the traction forming process. However, there are burrs on the edges of the punched holes, which will not only affect the subsequent production operations, but also reduce excessive burrs. The quality of equipment for forming fire doors will also reduce the service life of the equipment, and the burrs will easily cause scratches to the staff and users after the finished product, thereby reducing the promotion and use of the equipment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

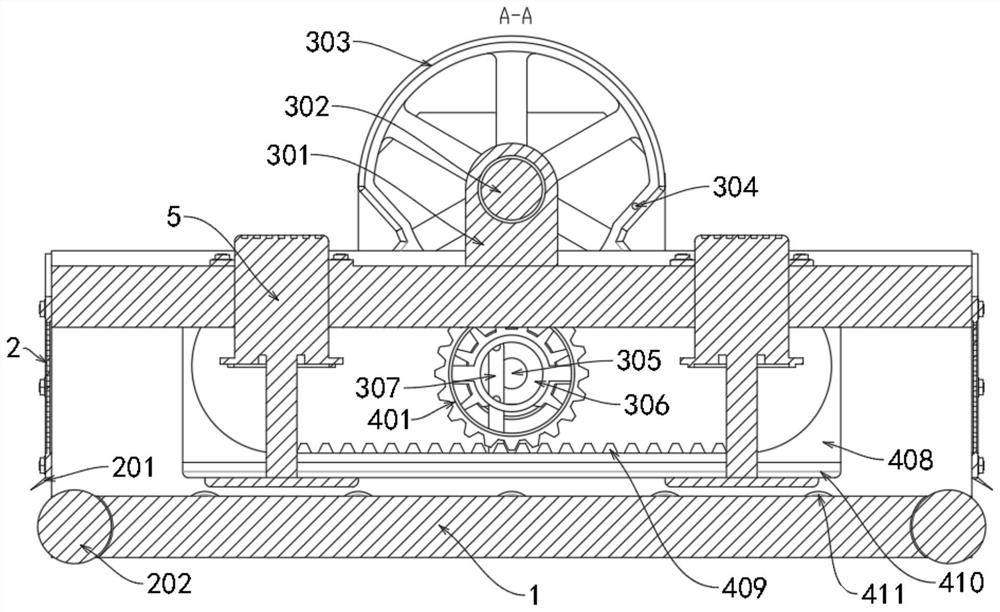

[0036] Under the action of the roller 202, the friction of the fire door plate during the pulling process can be reduced, thereby improving the fire door.

Embodiment 2

Embodiment 3

[0042] During operation, the intermittent second gear 401 can be rotated counterclockwise under the rotation of the first gear 306,

[0046] Under the action of the rotation of the first gear 306, the intermittent second gear 401 can be rotated counterclockwise, because the second

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

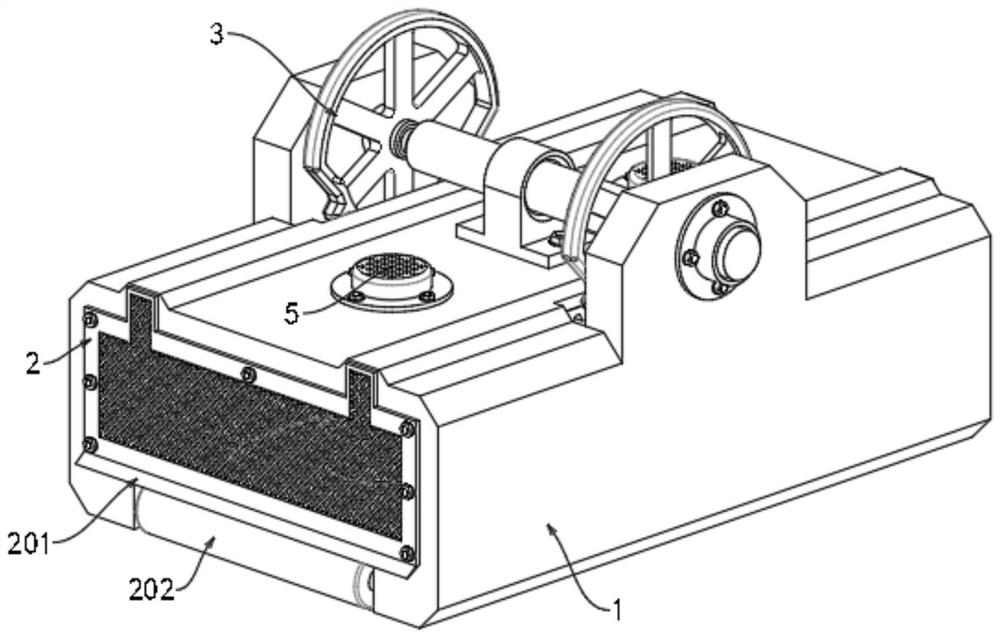

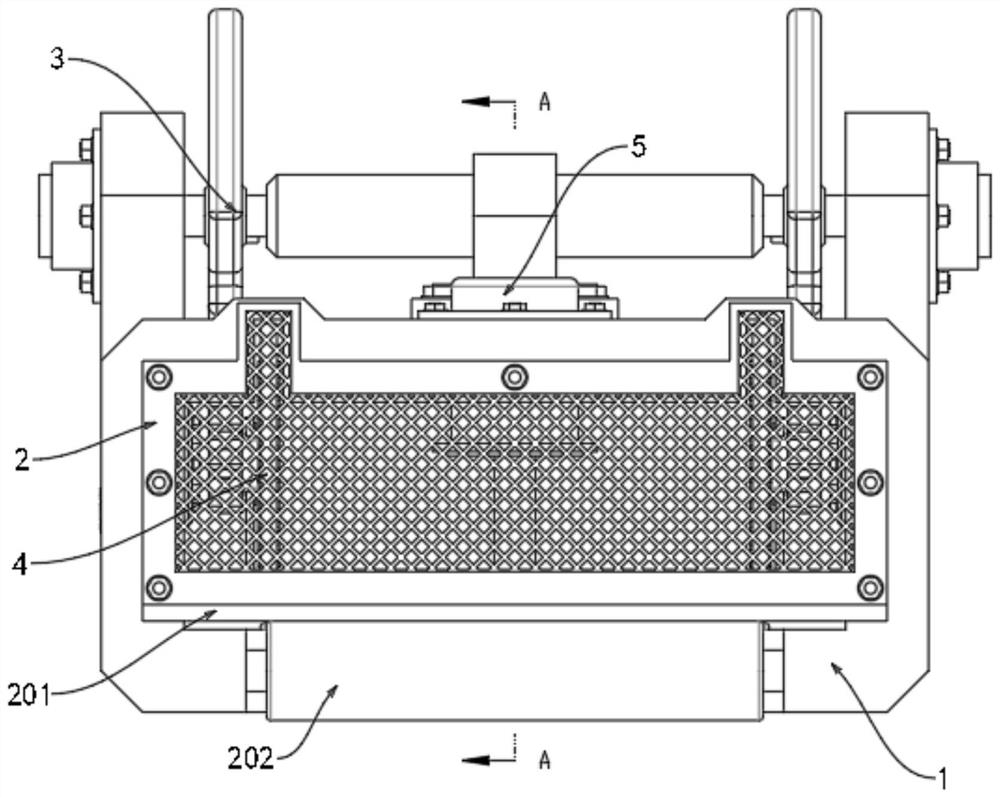

The plate forming device of the fire exit door comprises a workbench, the outer wall of the workbench is fixedly connected with a blocking net through bolts, the bottom of the blocking net is fixedly connected with a scraping strip, the portion, close to the bottom of the scraping strip, of the outer side of the workbench is rotationally connected with rolling wheels, and a transmission mechanism is arranged on the inner wall of the workbench; a traction mechanism is arranged in the workbench, the outer wall of the transmission mechanism is fixedly connected with the outer wall of the traction mechanism, and a grinding device is fixedly connected to the top of the workbench. When the fire exit door plate is conveyed, some holes and burrs machined on the surface of the plate can be polished, so that scratches of production workers caused by the burrs are reduced, meanwhile, the quality of the fire exit door plate is improved, scratches of customers caused by the burrs can be reduced when the fire exit door plate is used by users, and the safety of the equipment in the using process is improved.

Description

A kind of plate forming device for fire door technical field [0001] The present invention relates to the technical field of fire doors, in particular to a plate forming device for fire doors. Background technique [0002] In the production process of the fire door, it is necessary to punch holes of different sizes and shapes on the plate, and then draw them. forming process, but there are burrs on the edges of the punched holes, which will not only affect the subsequent production operations, but also have too many burrs. The burrs will reduce the quality of the equipment for the fire door molding, and will also reduce the service life of the equipment, and the burrs are easy to Risk of scratches to staff and users, thereby reducing the promotion and use of equipment. [0003] To this end, a plate forming device for a fire door is proposed. SUMMARY OF THE INVENTION The object of the present invention is to provide a kind of sheet metal forming device of fire door, in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B9/02B24B41/04B24B47/12B24B41/00B24B47/00B24B41/02B08B1/02

CPCB24B9/002B24B9/02B24B41/04B24B47/12B24B41/005B24B47/00B24B41/02B08B1/20B08B1/165

Inventor 陆卫斌

Owner 江苏久泰消防设备有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com