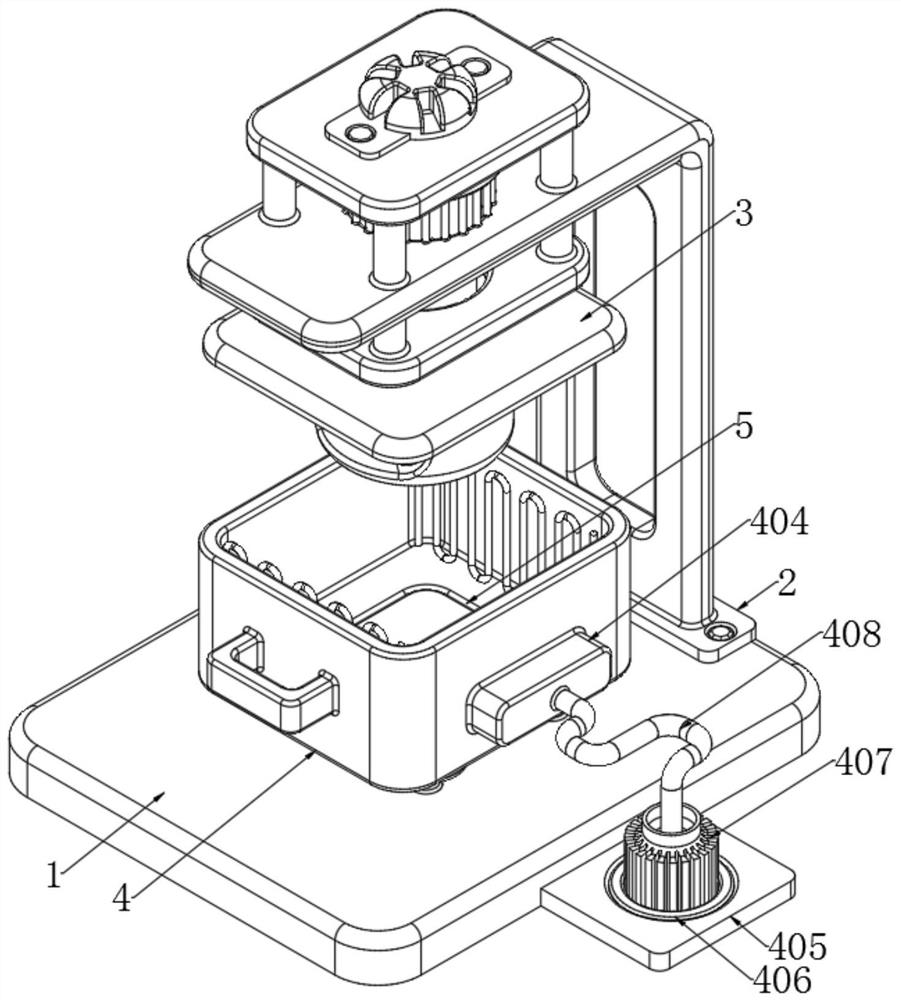

Pneumatic control device of large vacuum pressurization casting equipment and using method of pneumatic control device

A casting equipment and vacuum technology, which can reduce the difficulty, shorten the demoulding time, and accelerate the cooling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

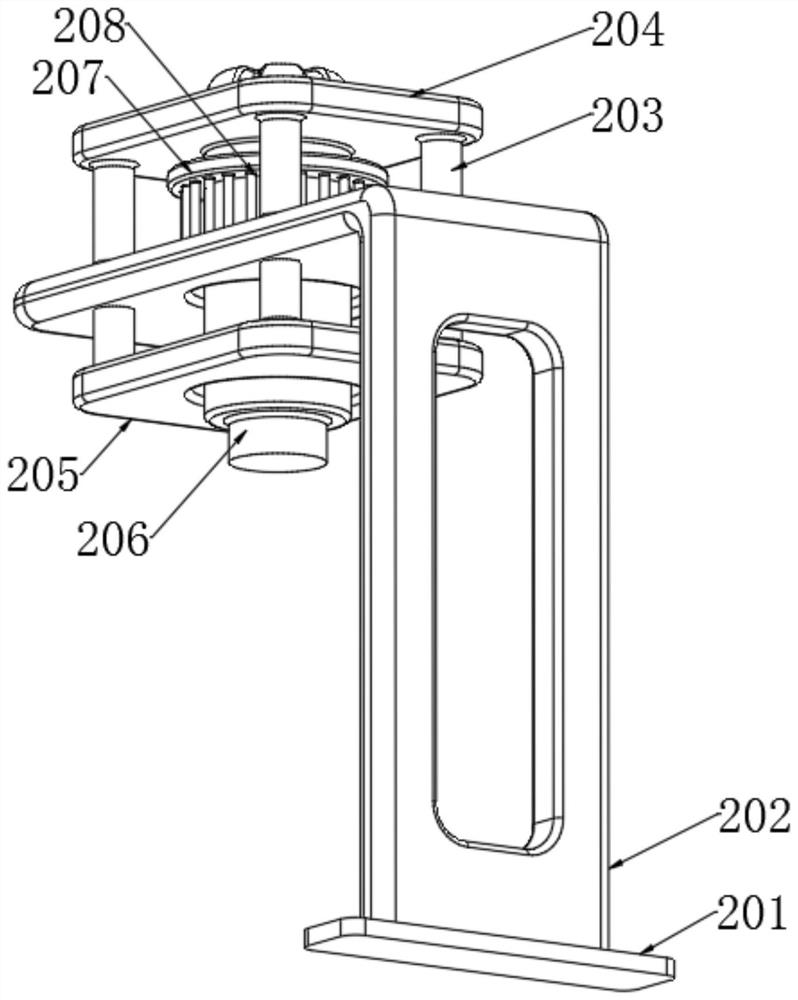

Method used

Image

Examples

Embodiment Construction

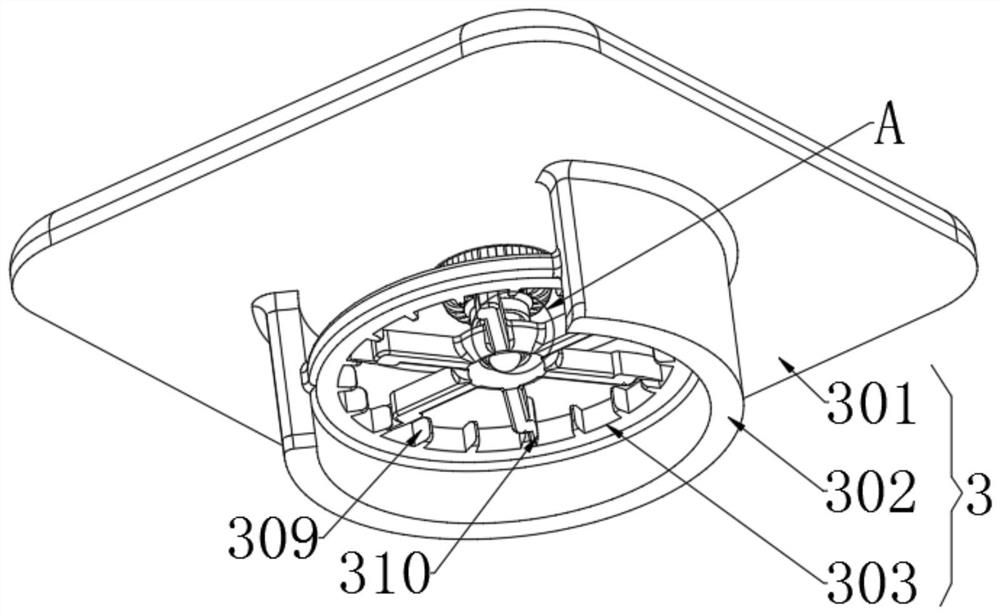

[0036] Step 3: Start the servo motor 304 to drive the metal shrapnel 310 on the connecting plate 308 to rotate at high speed in the casting head 302, and continuously collide with the surface of the buckle 309, so that the surface of the casting head 302 produces a higher vibration effect, and At the same time, the vibration effect on the surface of the casting head 302 will continue to diffuse into the liquid material, increasing the flow rate of the liquid material and squeezing the air bubbles in the liquid material.

[0037] Step 4: After the casting mold arrives for a period of time, start the refrigeration unit 407, and the refrigeration airflow generated during its work will be transported through multiple pipes and conducted into the condensation pipe 402, and at the same time, the cold air generated on the surface of the condensation pipe 402 will continue to dissipate To the receiving casing 401, a lower temperature environment is created for the liquid material in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com