Crack measuring device for hydraulic ring geological survey based on 3D scanning

A geological survey and measuring device technology, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve problems such as hidden dangers, high safety, and device movement, so as to avoid collision damage, improve safety, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

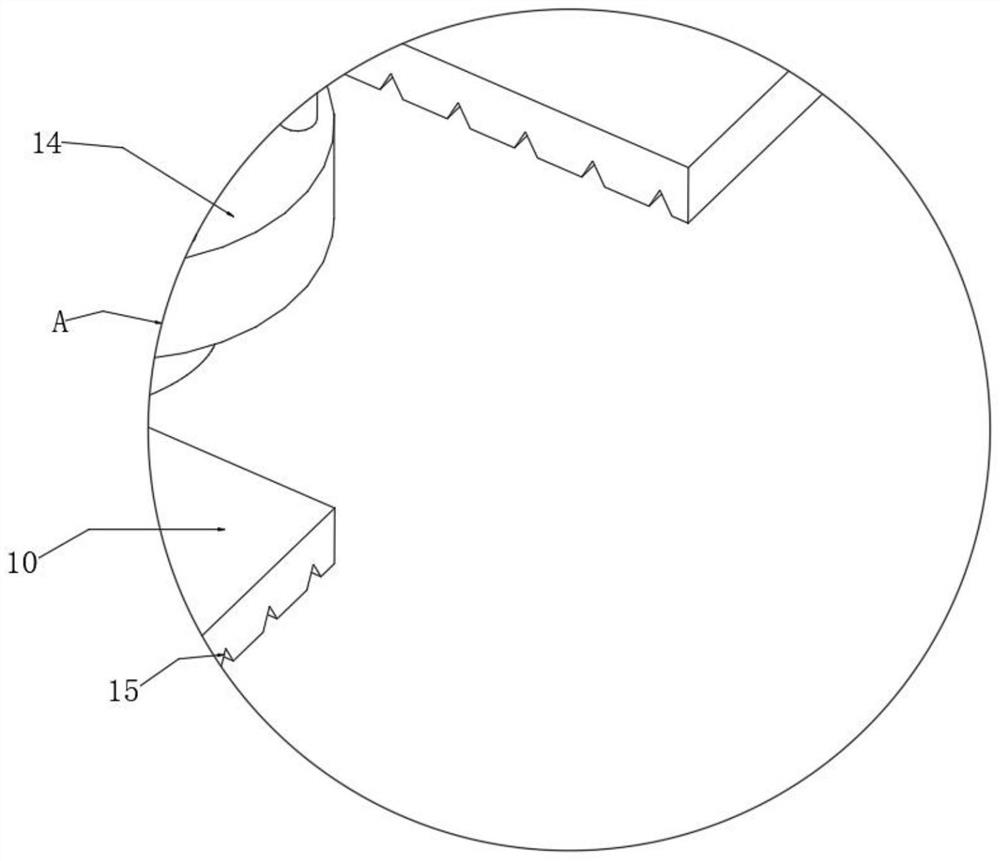

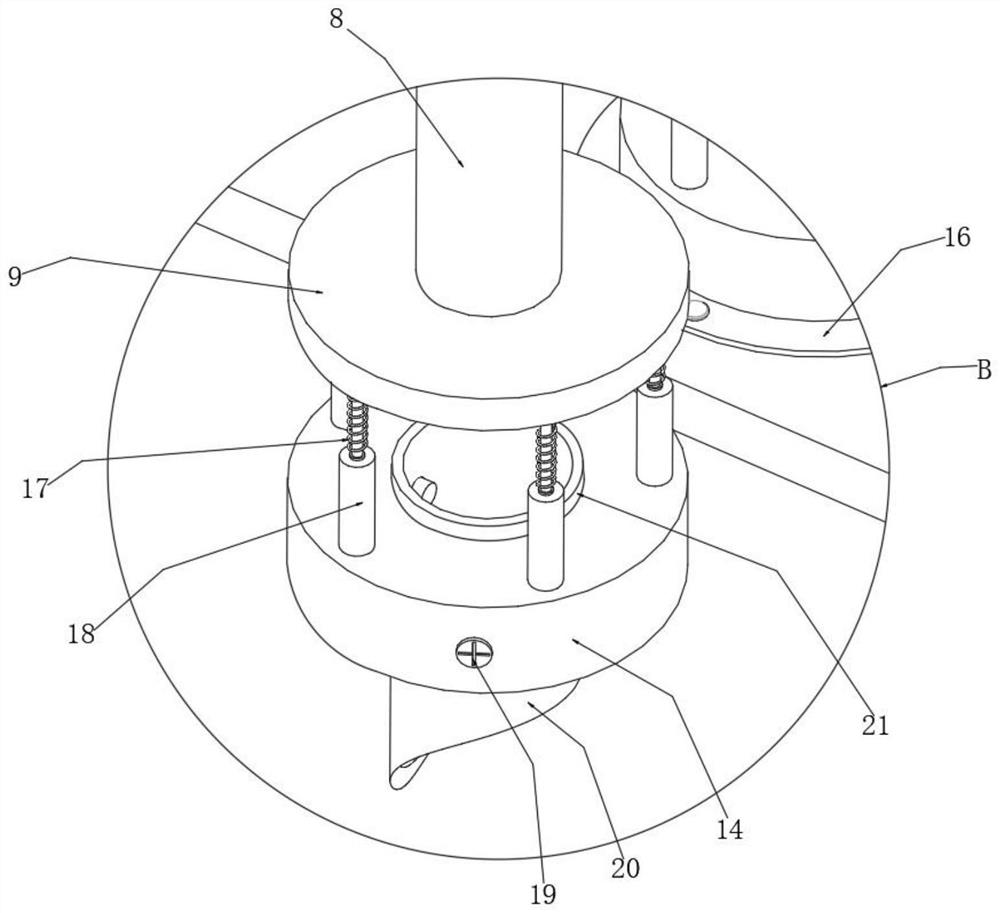

[0035] like Figure 1 to Figure 8 As shown, the embodiment of the present invention provides a 3D scanning-based crack measurement device for hydraulic ring geological survey, including a support plate 1, the cross section of the support plate 1 is an inverse L shape, and the top outer wall of the support plate 1 is provided with a concave Slot 3, the inner walls of both sides of the groove 3 are rotatably connected with a rotating column 2, the circumferential outer wall of the rotating column 2 is fixedly connected with a top plate 7, the bottom outer wall of the top plate 7 is provided with a positioning assembly, and the top of the support plate 1 is provided with a top plate for driving the top plate. 7 rotating pulling assembly, the bottom outer wall of the top plate 7 is provided with a driving assembly, one side of the driving assembly is fixedly connected with a fixing plate 45, the bottom of the fixing plate 45 is fixed with the first electric push rod 22, and the out...

Embodiment 2

[0054] like Figure 9 As shown, the embodiment of the present invention provides a 3D scanning-based fracture measuring device for hydraulic ring geological survey. Compared with Embodiment 1, the present embodiment further includes another connecting frame 25 fixedly connected to one side of a sprayer 51, The sprayer 51 is located on one side of the first detection rod 11 .

[0055] Working principle: The sprayer 51 arranged on one side of the first detection rod 11 can spray powder when the first detection rod 11 collides with the inner wall of the crack, so that traces can be left on the side of the cross rod 13, which is convenient for the staff The subsequent detection of the crack depth prevents the staff from being unable to obtain an accurate crack depth when the first detection rod 11 is recovered.

[0056]To sum up, with the help of the above technical solutions of the present invention, when the worker needs to measure the crack, the device can be moved to the area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com