Method for inducing calcium carbonate precipitation by combining plant urease with urease inhibitor

A urease inhibitor, calcium carbonate technology, applied in chemical instruments and methods, soil protection, fertilizer mixtures, etc., can solve the problems of large bacterial activity, difficult cultivation, instability, etc., to achieve slow reaction rate, good mechanical properties, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

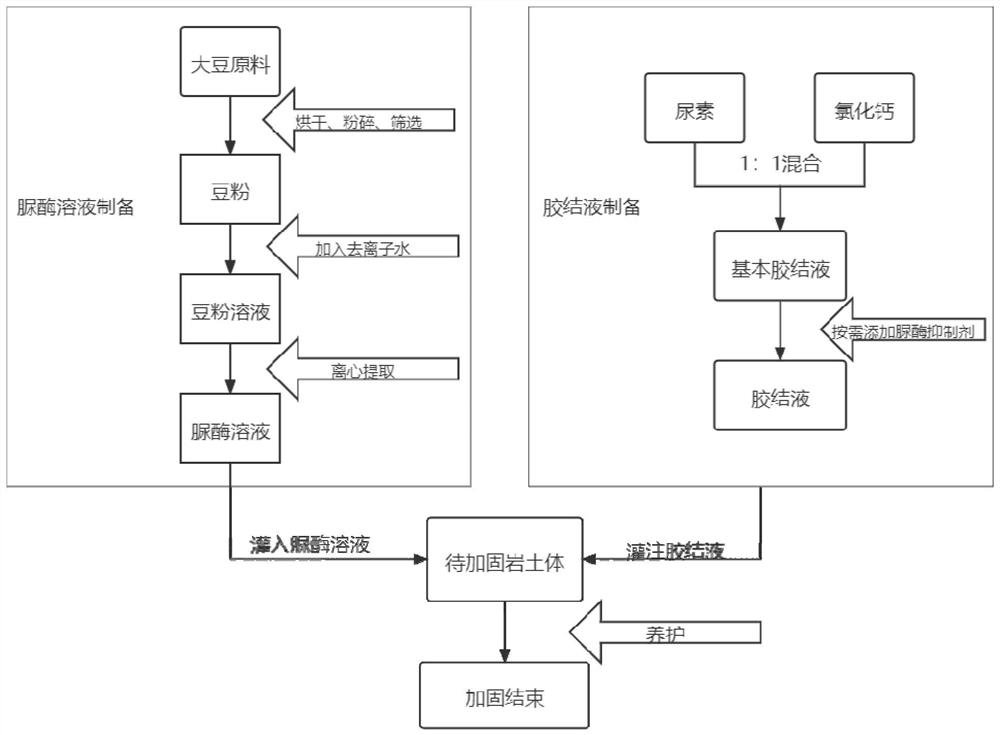

[0041] 1. Extract plant urease. Soybeans were dried in an oven at 40°C for 6 hours. After crushing, the soybean flour was sieved with a 100-mesh steel sieve. The soybean flour was mixed with deionized water to prepare a soybean flour solution with a mass concentration of 50 g / L. Stir the soy flour solution evenly, filter it through gauze into a beaker, and after standing for 2 to 3 hours, take the supernatant of the beaker and place it in a centrifuge tube at 3000 r / min and 4°C for 15 minutes, and take the supernatant from the centrifuge tube. The solution was stored at 4°C.

[0042] 2. Make the cementitious liquid. Calcium chloride and urea were mixed with analytical reagent in a ratio of 1:1, the mass concentration of the solution was 0.25mol / L, and the urease inhibitor n-butyl thiophosphoric triamide or NBPT was added, accounting for 1% of the total solution volume.

[0043] 3. Grouting reinforcement. Using a peristaltic pump, the urease solution and the cementing soluti...

Embodiment 2

[0045]1. Extract plant urease. Soybeans were dried in an oven at 40°C for 6 hours. After crushing, the soybean flour was sieved with a 100-mesh steel sieve. The soybean flour was mixed with deionized water to prepare a soybean flour solution with a mass concentration of 60 g / L. Stir the soy flour solution evenly, filter it through gauze into a beaker, and after standing for 2 to 3 hours, take the supernatant of the beaker, put it in a centrifuge tube and centrifuge it at 3000 r / min and 4°C for 15 minutes. The solution was stored at 4°C.

[0046] 2. Make cementation solution. Calcium chloride and urea were mixed with analytical reagents in a ratio of 1:1, the mass concentration of the solution was 0.25 mol / L, and the urease inhibitor n-butyl thiophosphoric triamide (NBPT) was added, accounting for 1% of the total solution volume.

[0047] 3. Grouting reinforcement. Use a peristaltic pump to pour the urease solution and the cementitious solution into the sand in turn, and cur...

Embodiment 3

[0049] 1. Extract plant urease. The soybeans were dried in an oven at 40°C for 6 hours. After crushing, the soybean powder was sieved with a 100-mesh steel sieve. The soybean powder was mixed with deionized water to prepare a soybean powder solution with a mass concentration of 50 g / L. Stir the soy flour solution evenly, filter it through gauze into a beaker, and after standing for 2 to 3 hours, take the supernatant of the beaker, put it in a centrifuge tube and centrifuge it at 3000 r / min and 4°C for 15 minutes. The solution was stored at 4°C.

[0050] 2. Make cementation solution. Calcium chloride and urea were mixed with analytical pure reagent in a ratio of 1:1, the mass concentration of the solution was 0.7 mol / L, and the urease inhibitor n-butyl thiophosphoric triamide or NBPT was added, accounting for 0.1% of the total solution volume.

[0051] 3. Grouting reinforcement. Utilize peristaltic pump to pour urease solution and cementitious liquid into the pores of rock m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com