Shading gasket glue formed in situ based on UV delayed curing and preparation method thereof

An in-situ, gasket technology, applied in the direction of adhesives, non-polymer organic compound adhesives, adhesive types, etc., can solve the problems of small molecular weight of the initiator, reduced curing effect, easy loss, etc. Loss, improve stability, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

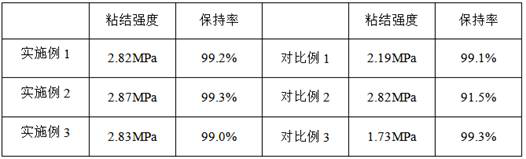

Examples

Embodiment 1

[0028] A light-shielding gasket formed in situ based on UV delayed curing, in parts by weight, mainly comprising: 30 parts of resin, 2 parts of active monomer, 5 parts of discoloration assistant, 1 part of photoinitiator and 1 part of octa-epoxy base octasilsesquioxane.

[0029] A preparation method of a light-shielding gasket glue formed in-situ based on UV delayed curing, the preparation method of the light-shielding gasket glue formed in-situ based on UV delayed curing mainly comprises the following preparation steps:

[0030] (1) Mix p-aminothiophenol, potassium hydroxide, 4-chlorobenzophenone in a mass ratio, toluene and N-methylpyrrolidone in a mass ratio of 5:2:8:60:20 and mix them evenly at 10°C. , stir at 300r / min for 30min, heat up to 120°C and hold for 4h, continue to heat up to 160°C and hold for 4h, cool to room temperature and filter to remove solid impurities to obtain a filtrate. The mass fraction of 38% hydrochloric acid and ice-water mixture is 1: 6. Mix eve...

Embodiment 2

[0035] A light-shielding gasket formed in situ based on UV delayed curing, in parts by weight, mainly comprising: 40 parts of resin, 3 parts of active monomer, 6.5 parts of discoloration assistant, 1.5 parts of photoinitiator and 2 parts of octa-epoxy base octasilsesquioxane.

[0036] A preparation method of a light-shielding gasket glue formed in-situ based on UV delayed curing, the preparation method of the light-shielding gasket glue formed in-situ based on UV delayed curing mainly comprises the following preparation steps:

[0037] (1) Mix p-aminothiophenol, potassium hydroxide, 4-chlorobenzophenone in a mass ratio, toluene and N-methylpyrrolidone in a mass ratio of 5:2.5:8.5:65:25. , stir at 400r / min for 25min, heat up to 125°C and hold for 3.5h, continue to heat up to 165°C and hold for 3.5h, cool to room temperature and filter to remove solid impurities to obtain a filtrate, the mass fraction of 37% hydrochloric acid and ice-water mixture by mass ratio 1:7 mix and conf...

Embodiment 3

[0042] A light-shielding gasket formed in situ based on UV delayed curing, in parts by weight, mainly comprising: 50 parts of resin, 4 parts of active monomer, 8 parts of discoloration assistant, 2 parts of photoinitiator and 3 parts of octa-epoxy base octasilsesquioxane.

[0043] A preparation method of a light-shielding gasket glue formed in-situ based on UV delayed curing, the preparation method of the light-shielding gasket glue formed in-situ based on UV delayed curing mainly comprises the following preparation steps:

[0044] (1) Mix p-aminothiophenol, potassium hydroxide, 4-chlorobenzophenone in a mass ratio, toluene and N-methylpyrrolidone in a mass ratio of 5:3:9:70:30 and mix them evenly at 30°C. , stir at 500r / min for 20min, heat up to 130°C and hold for 3h, continue to heat up to 170°C and hold for 3h, cool to room temperature and filter to remove solid impurities to obtain a filtrate. The mass fraction of 36% hydrochloric acid and ice-water mixture is 1: 8 Mix an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com