Automatic wheat flour bagging machine

A bagging machine and wheat flour technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inability to carry out assembly line operations, low production efficiency, and low degree of automation, and achieve the goal of avoiding equipment contamination and moving structures Jamming, reduced labor costs, excellent anti-blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the specific embodiments and the accompanying drawings. It should be noted that the embodiments of the present invention and the features in the embodiments may be combined with each other under the condition of no conflict.

[0032] It is understood that these descriptions are exemplary only and are not intended to limit the scope of the invention.

[0033] The following describes an automatic bagging machine for wheat flour provided by some embodiments of the present invention with reference to the accompanying drawings.

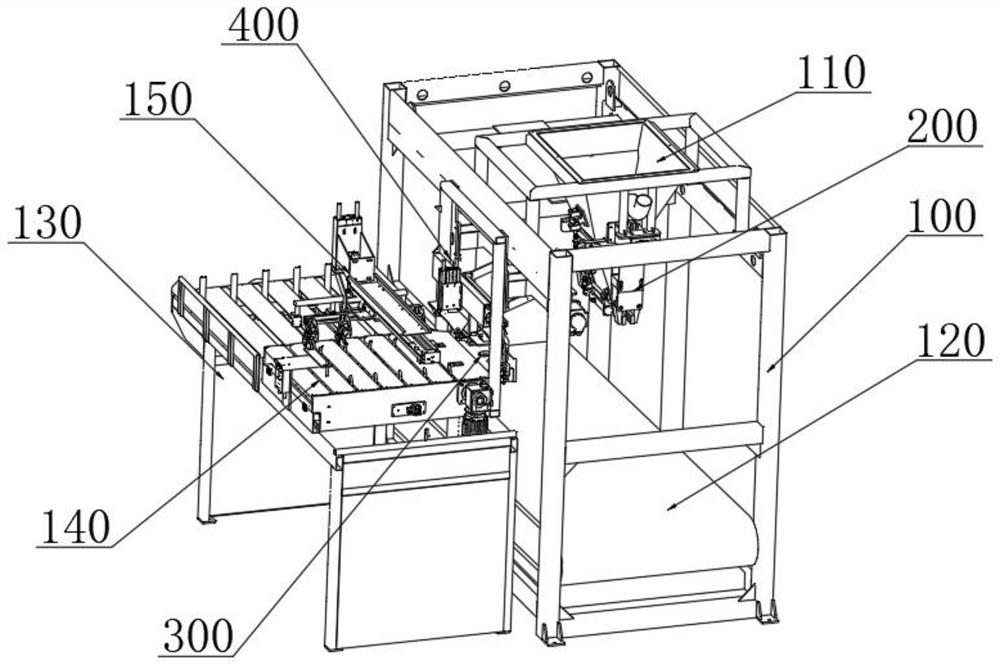

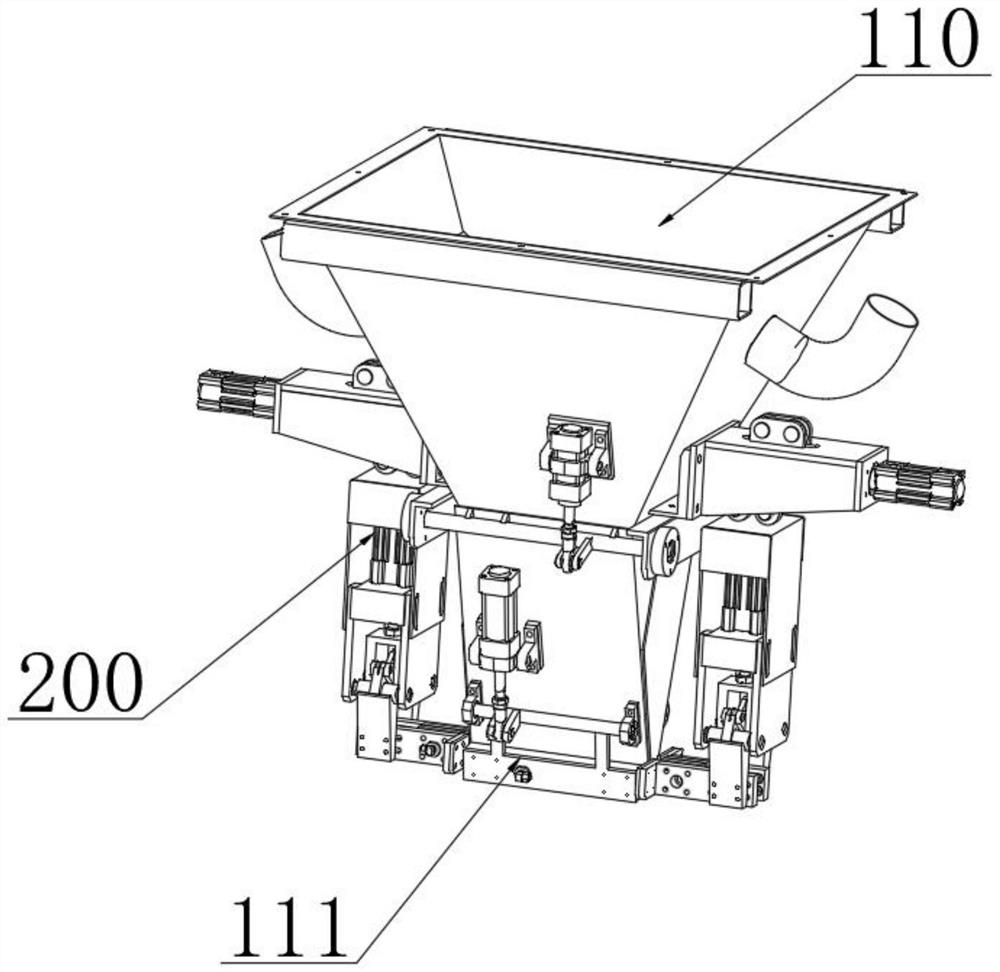

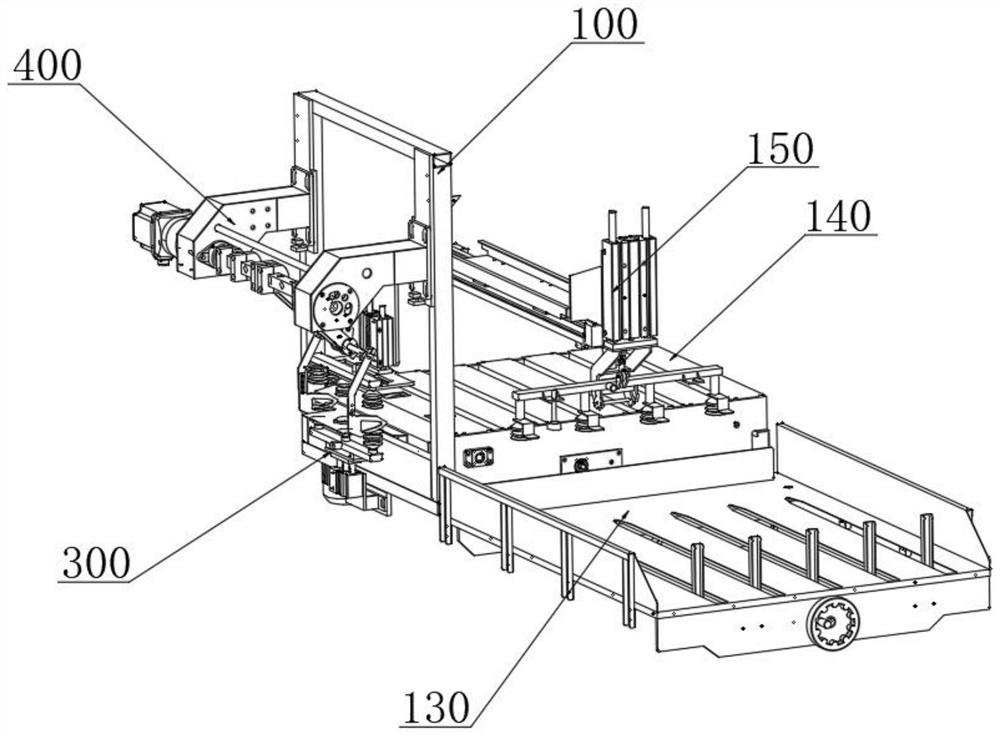

[0034] combine Figure 1-8As shown, an automatic bagging machine for wheat flour provided by the present invention includes: a fixed frame body 100, a pneumatic bag support mechanism 200 fixed on the surface of the fixed frame body 100, a suction cup bag opening mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com