Method for forming inner cavity of high-temperature alloy hollow guide vane

A high-temperature alloy, hollow-guided technology, applied to casting molding equipment, cores, molds, etc., can solve problems such as uneven wall thickness, recrystallization restrictions, etc., to reduce production costs, reduce recrystallization tendency, and easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

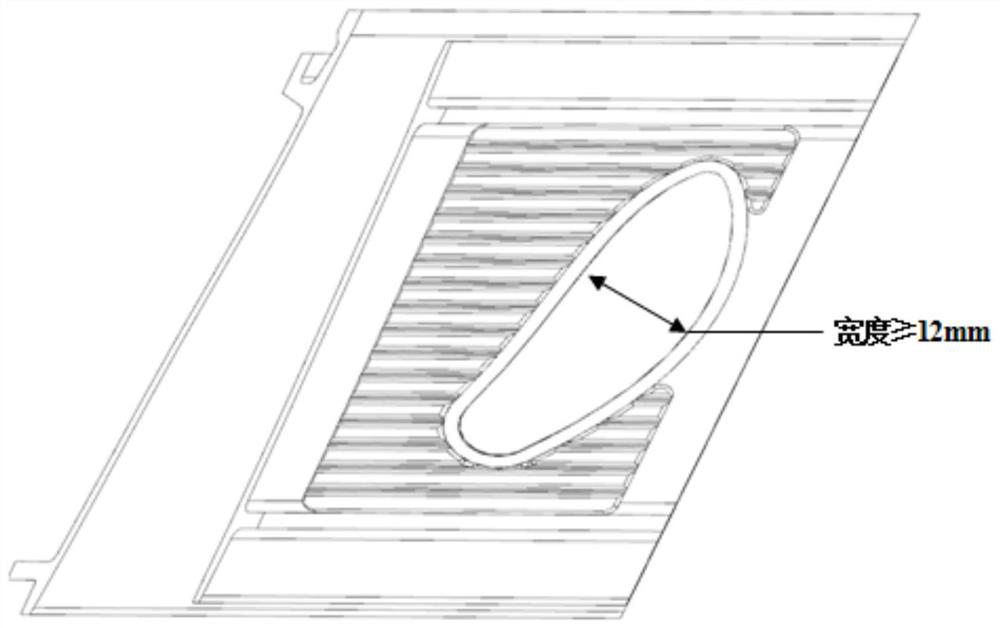

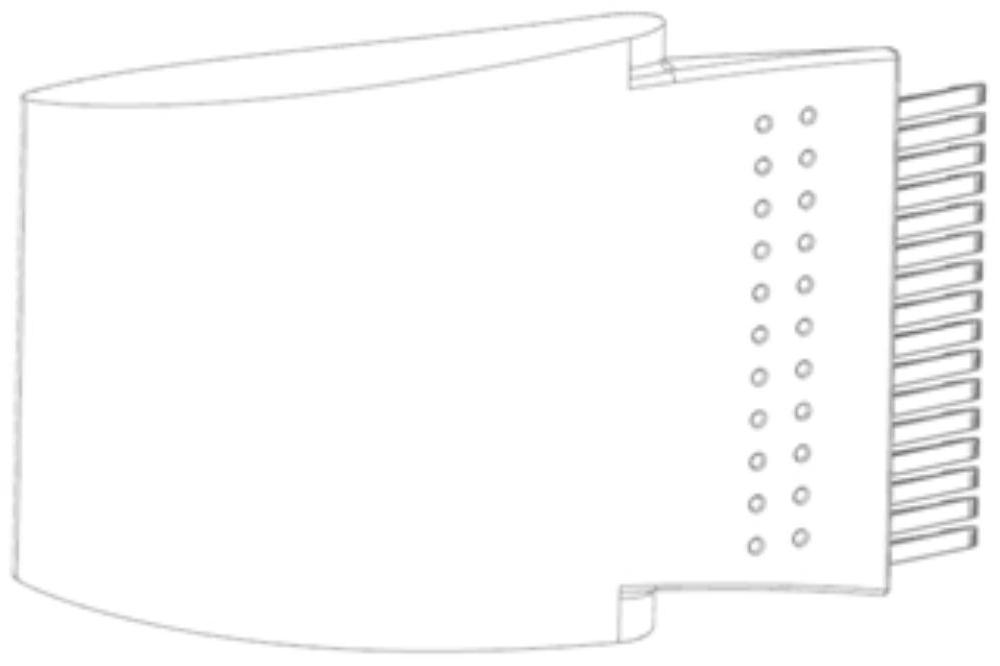

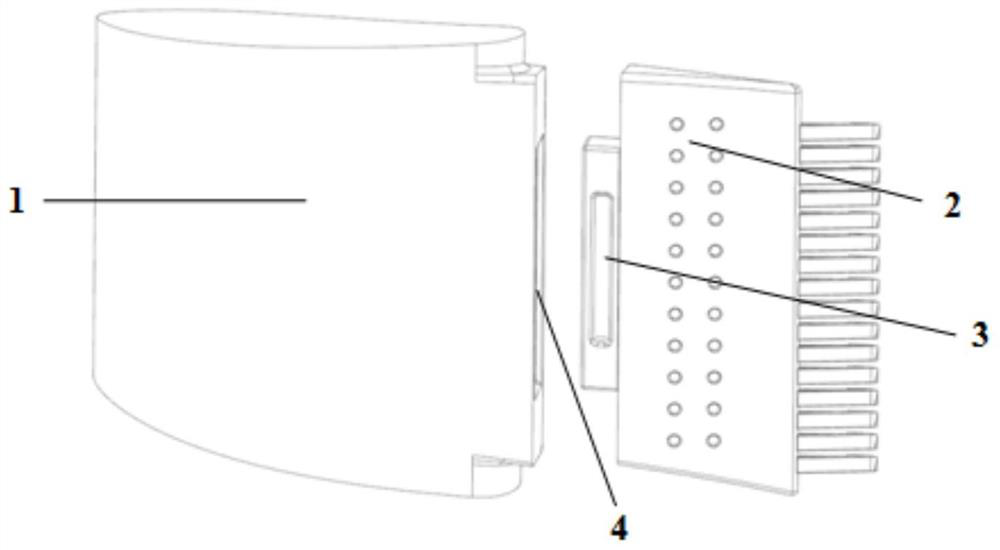

[0027] This embodiment is a case of preparing an equiaxed superalloy hollow guide vane by combining a water-soluble core and a ceramic core. The size of this blade is large: 305mm long, 260mm wide, and 185mm high. Using a single ceramic core to prepare castings is prone to cracks, eccentric cores, leaky cores, out of tolerance wall thickness and core-shell shrinkage differences resulting in inclusions and other defects. Measure the core channel of the inner cavity of the blade, the width is 43mm, the inner cavity structure of the intake side can be formed by the shell, and the inner cavity of the exhaust side is smaller in size and formed by the core. When designing the mold, the overall core is divided into two parts: the exhaust side and the intake side. The mold is designed. The core mold, the ceramic core and the water-soluble core are provided with a combined structure, and the ceramic core is provided with a fixed end positioning structure. When preparing the inner cav...

Embodiment 2

[0030] This embodiment is a case of preparing a single crystal superalloy hollow guide vane by combining a water-soluble core and a ceramic core. The size of this blade is large: the length is 180mm, the width is 115mm, and the height is 95mm. Using a single ceramic core to prepare a casting is prone to cracks, eccentric cores, leaky cores, out of tolerance wall thickness and core-shell shrinkage differences. and other defects. Measure the core channel of the inner cavity of the blade, the width is 32mm, the inner cavity structure of the intake side can be formed by the shell, and the inner cavity of the exhaust side is smaller in size and formed by the core. When designing the mold, the overall core is divided into two parts: the exhaust side and the intake side. The mold is designed. The core mold, the ceramic core and the water-soluble core are provided with a combined structure, and the ceramic core is provided with a fixed end positioning structure. When preparing the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com