Processing device and method for determining winding temperature calculation model

A technology of computing models and processing devices, applied in the field of model parameter adjustment, can solve problems such as difficulty in properly detecting winding temperature, and achieve the effect of accurate temperature estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

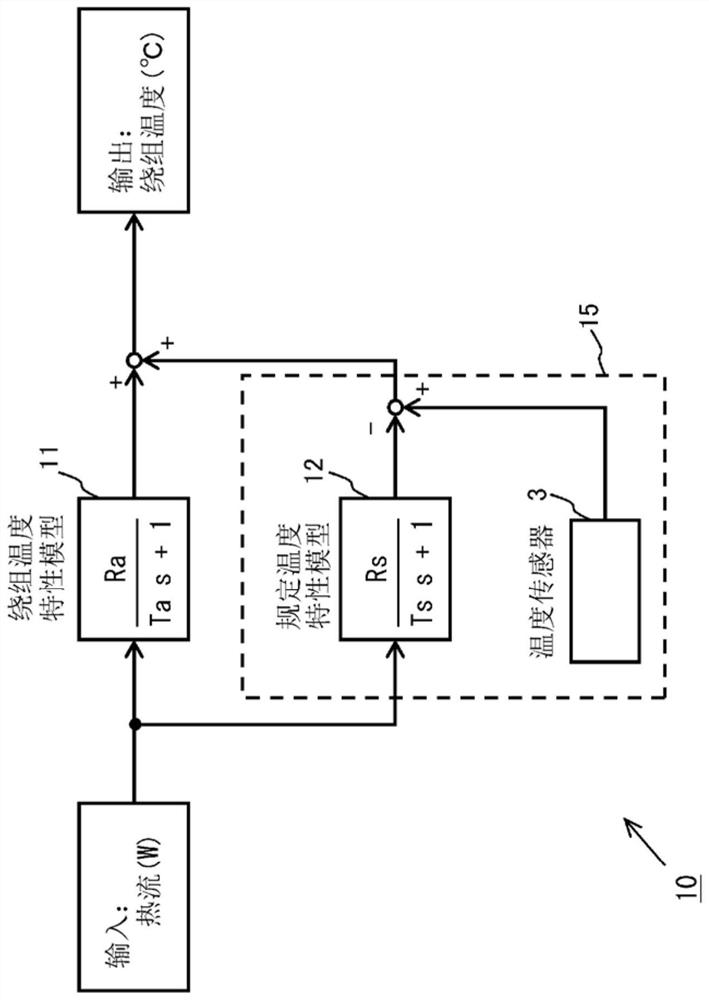

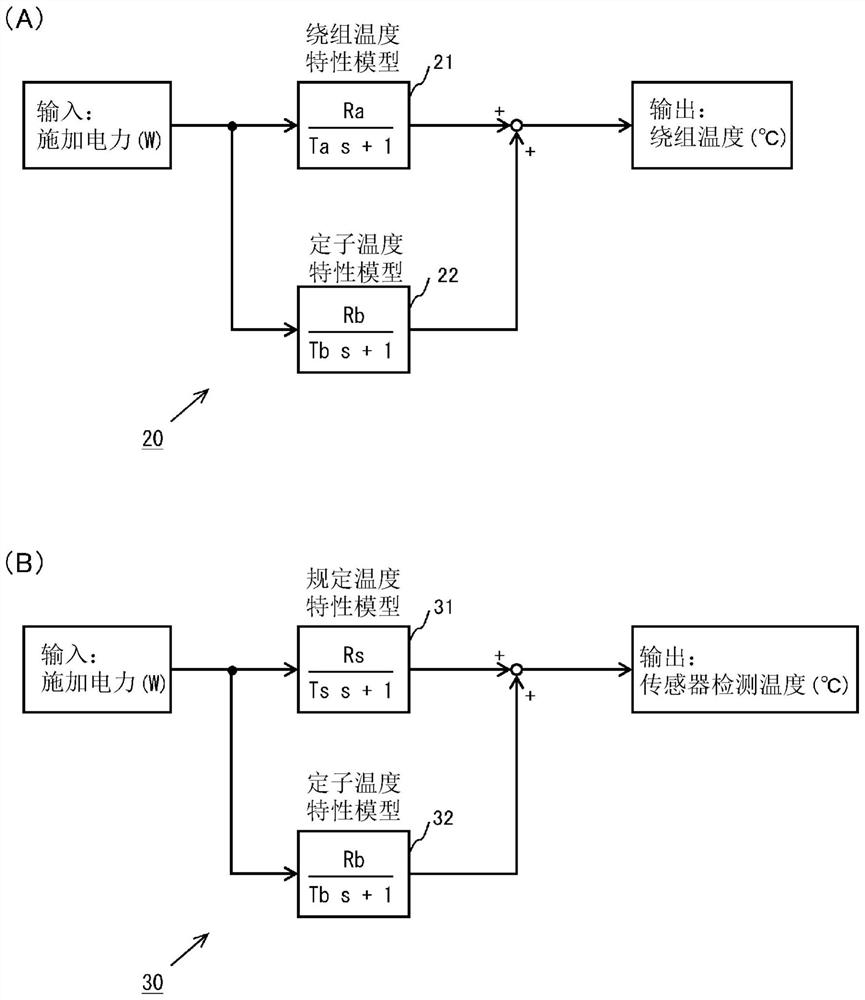

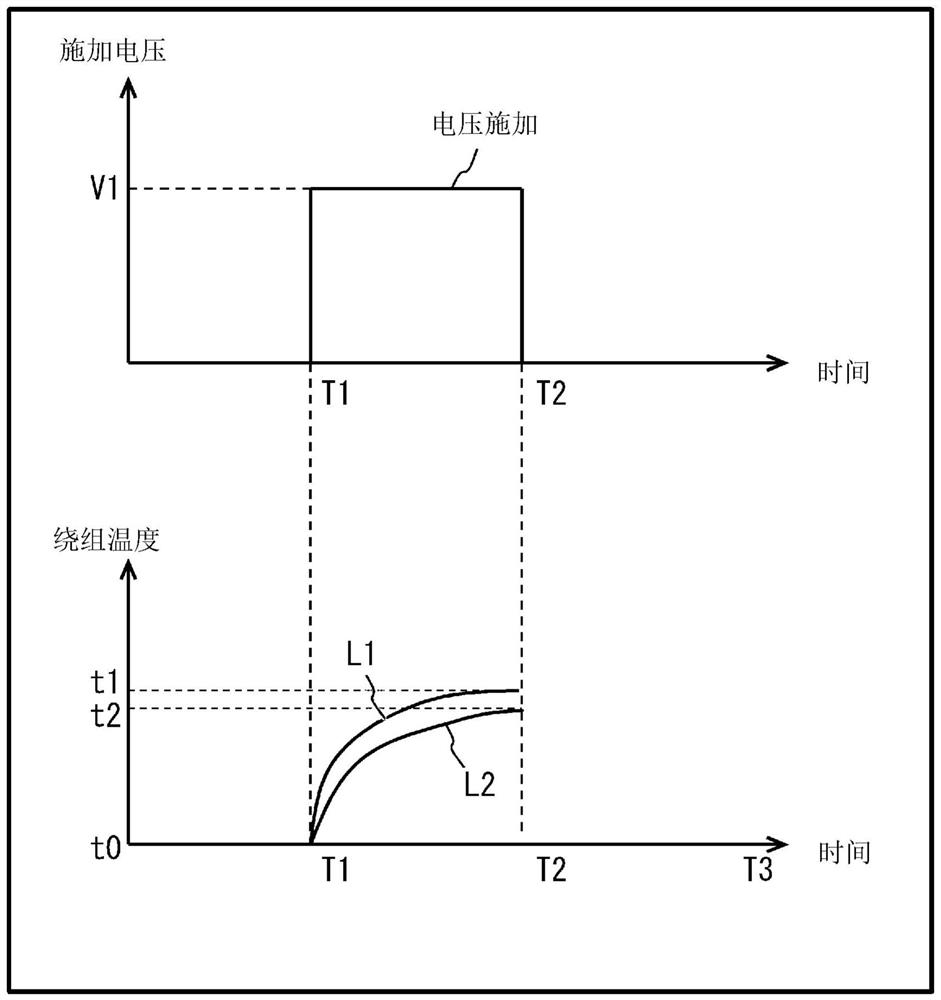

[0037] based on Figure 1 to Figure 3 For motor 2 with electronic thermal relay (see Figure 4 ), an example of a processing device that performs adjustment of model parameters for estimating the temperature of the motor winding by the electronic thermal relay will be described. In addition, in the embodiment of the present disclosure, the motor 2 only needs to have a structure in which the stator is wound with windings and has a rotor, and the specific structure thereof is not limited to a specific structure. In addition, inside the motor 2, a temperature sensor 3 is arranged so as to detect the temperature of the winding. More specifically, the detection portion of the temperature sensor 3 is located in the vicinity of the winding, and the detection portion is preferably in contact with the winding. A temperature sensor 3 is arranged in this manner.

[0038] here, figure 1 The schematic configuration of the calculation model 10 for calculating the winding temperature incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com