Rotating electric machine control system and vehicle drive system including the rotating electric machine control system

A technology for rotating electrical machines and control systems, applied in control systems, motor control, motor generator control, etc., can solve problems such as the voltage increase of the frequency conversion part, and achieve the effect of suppressing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

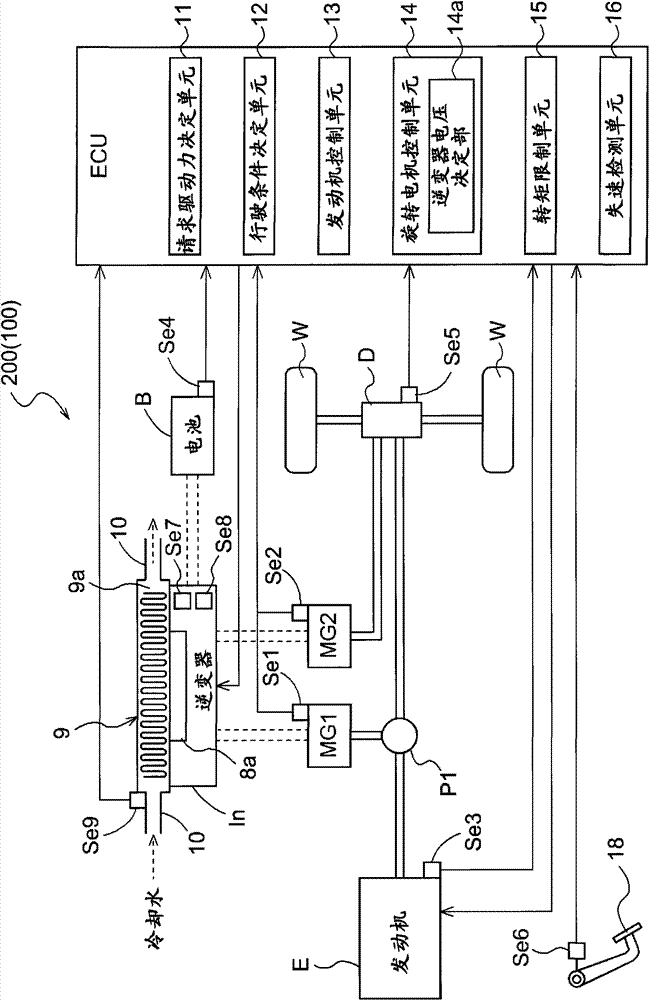

[0073] Hereinafter, an embodiment of the rotating electrical machine control system 100 according to the present invention will be described with reference to the drawings. The rotating electrical machine control system 100 is assembled in image 3 , represents the overall vehicle drive system 200 , which is used to control the operation of the rotary electric machines MG1 and MG2 included in the vehicle drive system 200 .

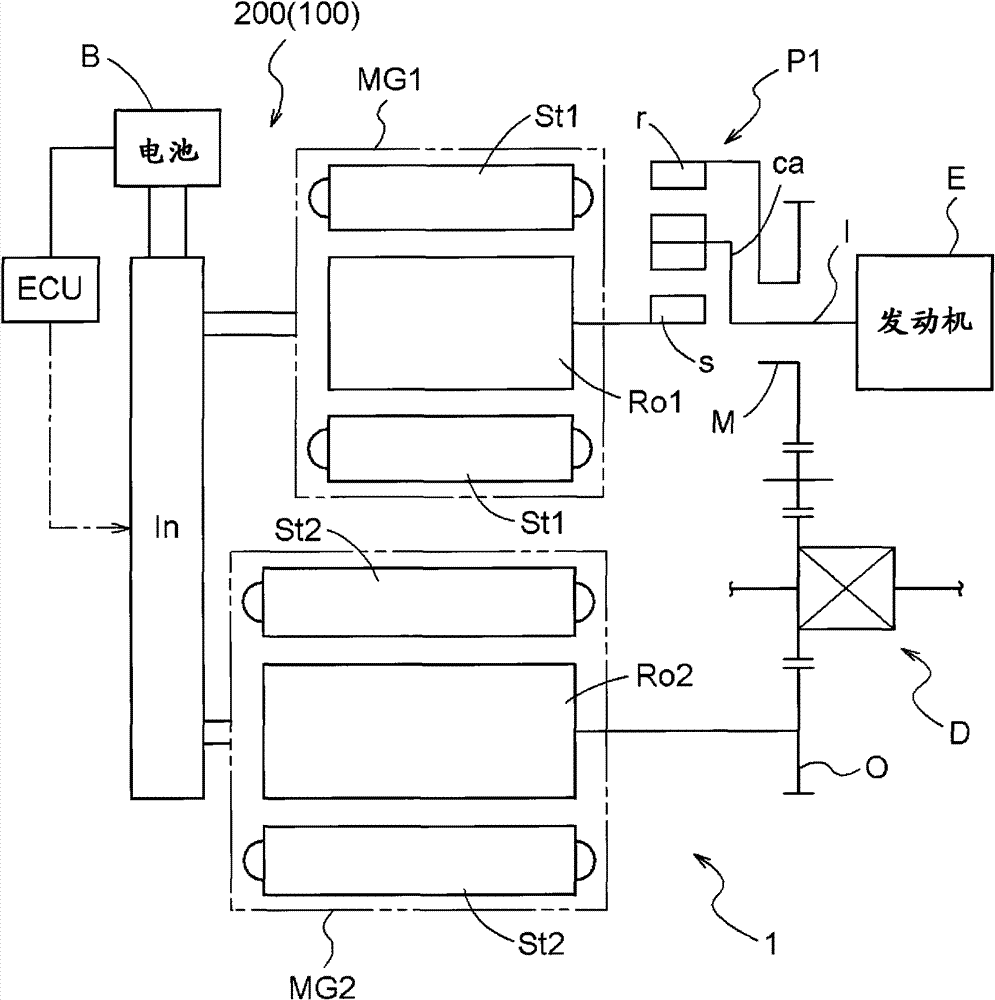

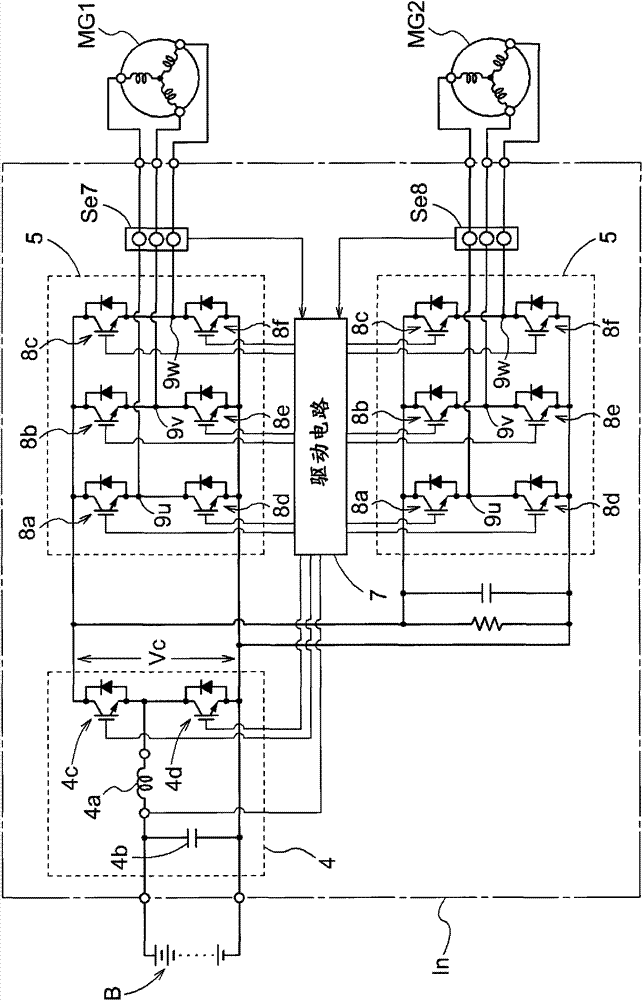

[0074] figure 1 is a schematic diagram showing the drive system of the vehicle drive system 200, figure 2 It is a schematic diagram showing a rotary electric machine control system mainly including an inverter In provided for controlling the rotary electric machines MG1 and MG2. image 3 It is a schematic diagram showing the whole of the vehicle drive system 200 including the control device ECU unique to the present application. image 3 The arrows in the middle solid line represent the transmission routes of various information, the double solid lines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com