Eddy current flaw detection device for defects of inner wall of engine cylinder sleeve

An engine cylinder, eddy current flaw detection technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low overall detection efficiency, poor automation degree of cylinder liner detection, etc., to improve the degree of automation and detection efficiency, improve the degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

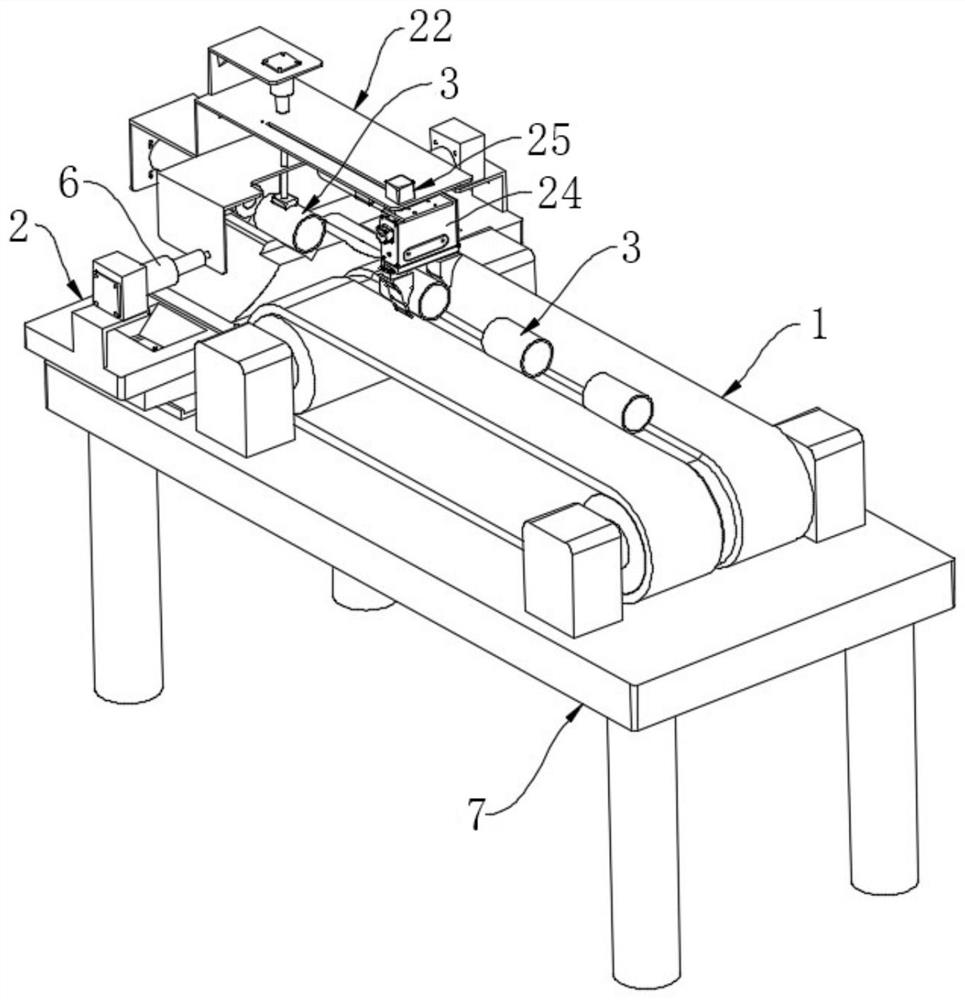

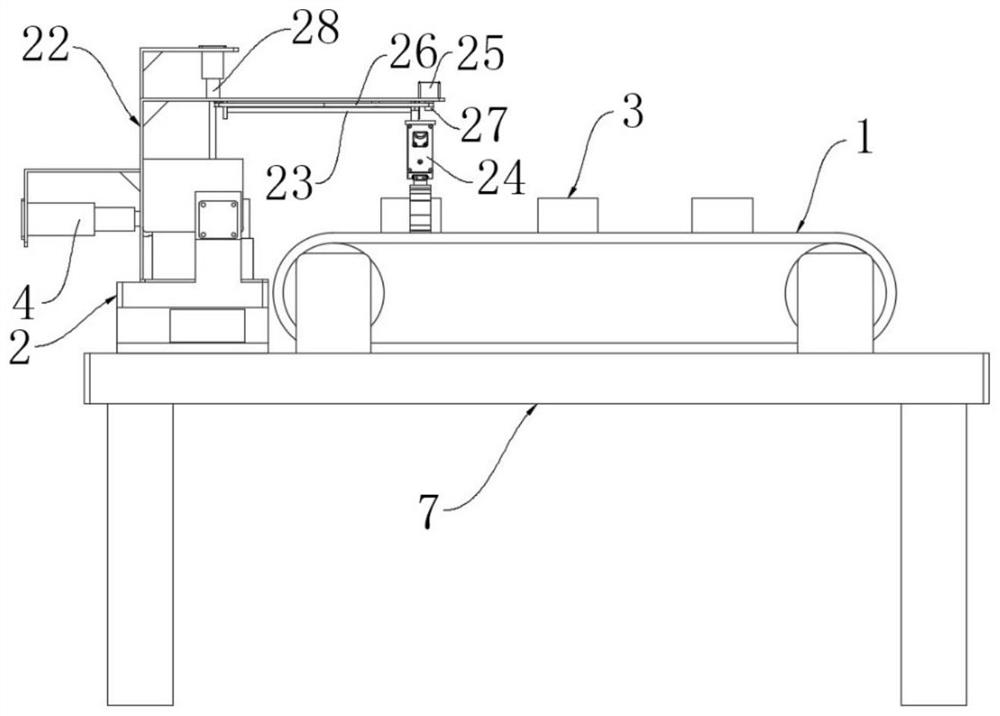

[0027] like Figure 1-3 The shown eddy current flaw detection device for defects in the inner wall of the engine cylinder liner includes a conveying mechanism 1 and a detection table 2 located at the discharge end of the conveying mechanism;

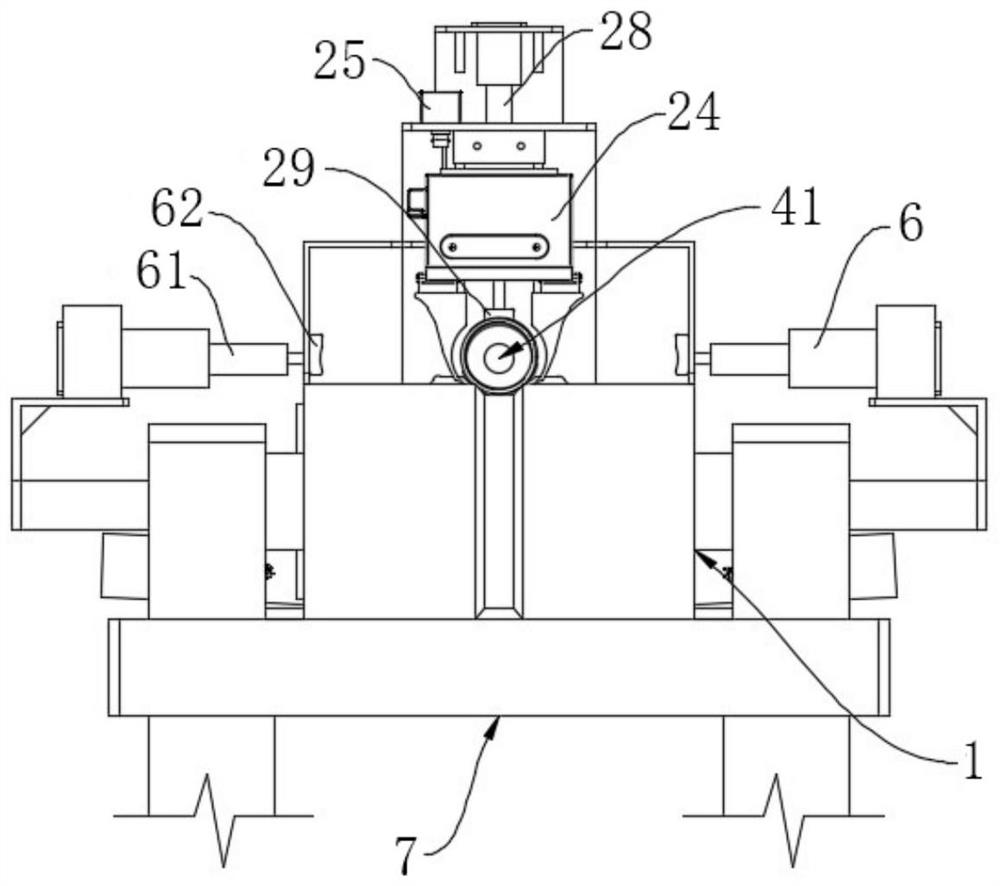

[0028] The upper end surface of the detection table 2 is provided with a V-shaped groove 21 for limiting the position of the cylinder liner 3, and the length direction of the V-shaped groove is consistent with the feeding direction of the conveying mechanism; The mounting frame 22 is fixedly connected with the testing table by screws; the mounting frame is provided with a clamping mechanism capable of moving the cylinder liner to the V-shaped groove, and a pressing force for fixing the cylinder liner in the V-shaped groove along the vertical direction The telescopic mechanism and the telescopic mechanism 4, the telescopic end of the telescopic mechanism is fixed with a flaw detection device 41 that can extend into the cylinder liner.

...

Embodiment 2

[0035] On the basis of Example 1, as figure 1 , 3 As shown in , 4 and 6, along the feeding direction of the conveying mechanism 1, the left and right sides of the detection table 2 are also symmetrically provided with a discharge slot 5 and a discharge mechanism 6. The edge of the V-shaped groove 21 is connected to the The edge of the material slot 5 is connected by the arc surface transition, so that the cylinder liner 3 can automatically roll down into the discharge slot more smoothly and smoothly, so as to ensure that the cylinder liner can obtain enough momentum to ensure that it can roll to the discharge Inside the slot; the discharging mechanism includes two horizontally arranged discharging cylinders 61 and a top block 62 fixedly arranged at the telescopic end of the discharging cylinder. The other side is pushed out and rolled down to the discharge slot along the curved surface.

[0036] Wherein, the top block 62 is also made of nylon material or rubber material, so ...

Embodiment 3

[0039]On the basis of Embodiment 1 or Embodiment 2, the eddy current flaw detection device for engine cylinder liner inner wall defects according to the present invention further includes a frame 7, and both the conveying mechanism 1 and the inspection table 2 are installed on the frame. surface, so that the conveying mechanism and the inspection table form an integral structure, so that the position between the conveying mechanism and the inspection table is fixed, so that the conveying mechanism and the inspection table maintain high positional accuracy. At the same time, it is also convenient to carry out the overall position adjustment and transportation according to the workshop production line, which improves the convenience of the overall position adjustment and transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com