Bridge cavity crack detector

A crack detector and cavity technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult operation of devices, bridge destruction, and affecting the safe use of bridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

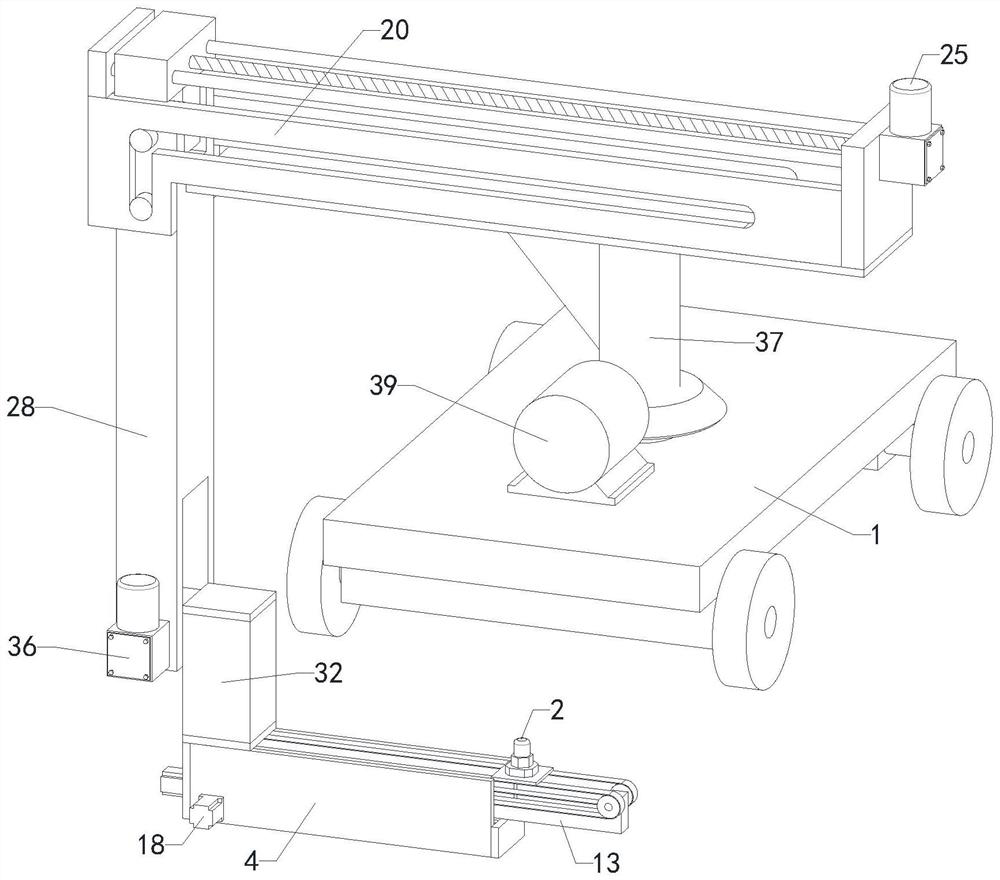

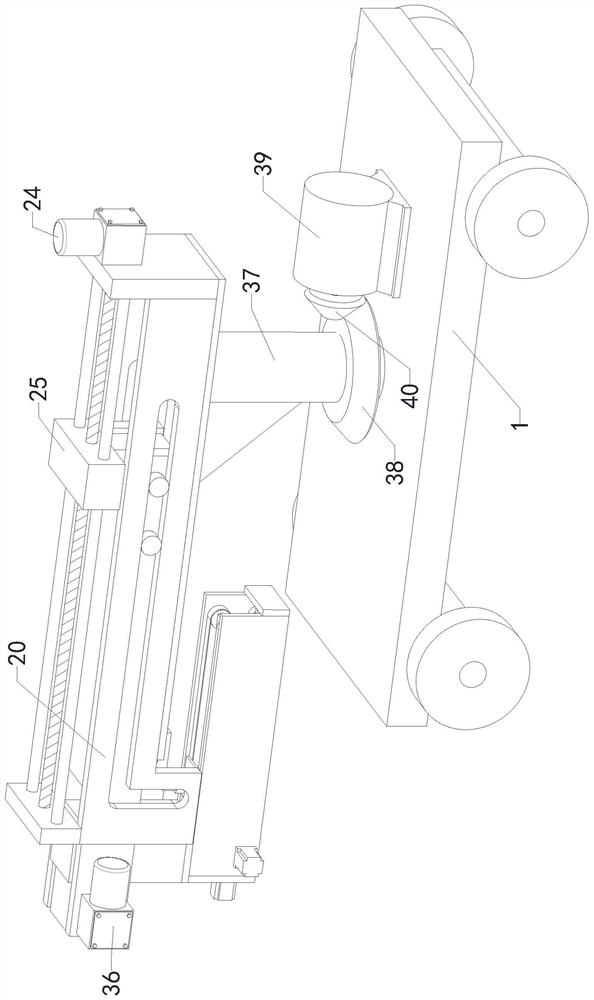

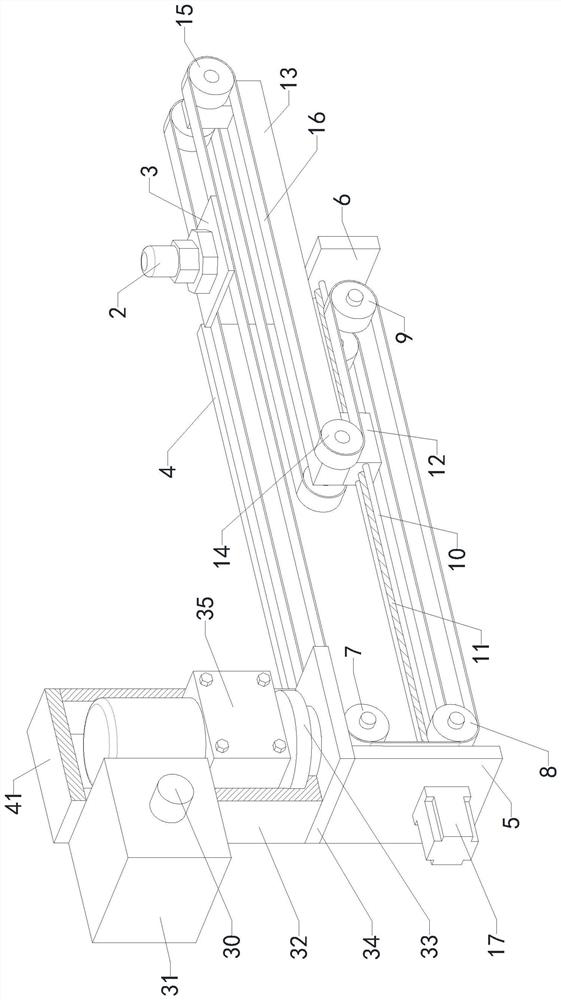

[0020] like Figure 1 to Figure 4 As shown, the support shaft 37 is rotatably installed on the vehicle frame 1, the support plate 19 is fixedly installed on the upper end of the support shaft 37, the first bevel gear 38 is fixedly installed on the support shaft 37, the motor 39 is fixedly installed on the vehicle frame 1, and the second bevel gear 38 is fixedly installed on the support shaft 37. The bevel gear 40 is fixedly connected with the output end of the motor 39, and the second bevel gear 40 and the connecting arm 28 are meshed with each other. On the right end face of the second set of fixing plates 20, the baffle D22 is fixedly installed on the left part of the upper end face of the two sets of second fixing plates 20, and the two sets of second sliding bars 23 are symmetrically and fixedly installed in the middle of the baffle D22 and the baffle C21. The second lead screw 24 is rotatably installed between the baffle D22 and the baffle C21, the first deceleration motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com