Novel environment-friendly refining agent and preparation method thereof

A refining agent and environmental protection technology, applied in the field of new environmental protection refining agent and its preparation, can solve the problems of non-environmental protection, high energy consumption, etc., achieve good submerged arc insulation effect, reduce furnace lining burning loss, and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

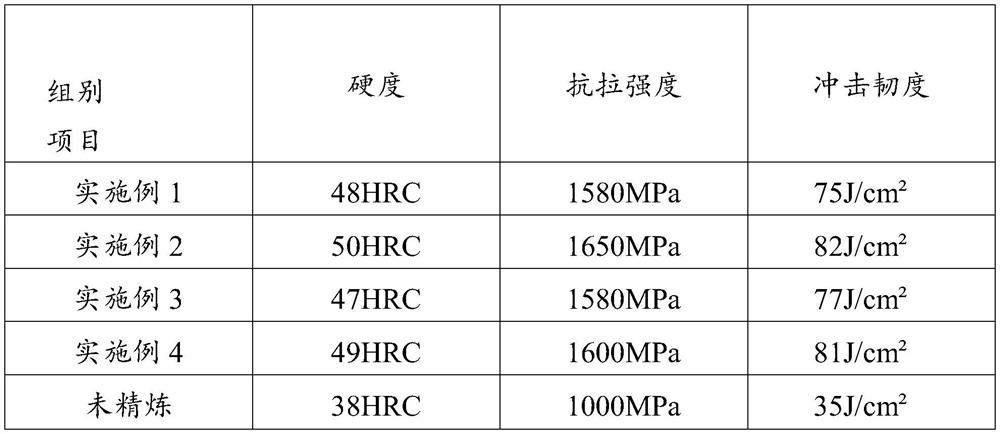

Examples

Embodiment 1

[0021] The new environmentally friendly refining agent is composed of aluminum, calcium oxide, aluminum oxide, silicon dioxide and magnesium oxide, and the mass ratio is aluminum: calcium oxide: aluminum oxide: silicon dioxide: magnesium oxide = 23.0: 20.0: 25.0: 2.0 : 2.0.

[0022] A preparation method of a novel environmentally friendly refining agent, using the above-mentioned raw material ratio, comprises the following steps:

[0023] 1) will select aluminum, calcium oxide, aluminum oxide, silicon dioxide and magnesium oxide to dry, pulverize and sieve in the vacuum reactor according to the mass fraction ratio to obtain the mixture;

[0024] 2) the mixture obtained in step 1) is made into granules by pressure forming and granulation, and the particle size of the granules is 5-50mm;

[0025] 3) The granules obtained in step 2) are sealed and stored in a moisture-proof bag.

[0026] Further, in step 1), the drying temperature of the vacuum reactor is 40-60° C., and the moi...

Embodiment 2

[0031] The new environmentally friendly refining agent is composed of aluminum, calcium oxide, aluminum oxide, silicon dioxide and magnesium oxide, and the mass ratio is aluminum: calcium oxide: aluminum oxide: silicon dioxide: magnesium oxide = 25.0: 25.0: 30.0: 3.5 : 5.0.

[0032] A preparation method of a novel environmentally friendly refining agent, using the above-mentioned raw material ratio, comprises the following steps:

[0033] 1) will select aluminum, calcium oxide, aluminum oxide, silicon dioxide and magnesium oxide to dry, pulverize and sieve in the vacuum reactor according to the mass fraction ratio to obtain the mixture;

[0034] 2) the mixture obtained in step 1) is made into granules by pressure forming and granulation, and the particle size of the granules is 5-50mm;

[0035] 3) The granules obtained in step 2) are sealed and stored in a moisture-proof bag.

[0036] Further, in step 1), the drying temperature of the vacuum reactor is 40-60° C., and the moi...

Embodiment 3

[0041] The new environmentally friendly refining agent is composed of aluminum, calcium oxide, aluminum oxide, silicon dioxide and magnesium oxide, and the mass ratio is aluminum: calcium oxide: aluminum oxide: silicon dioxide: magnesium oxide = 27.0: 30.0: 35.0: 5.0 : 8.0.

[0042] A preparation method of a novel environmentally friendly refining agent, using the above-mentioned raw material ratio, comprises the following steps:

[0043] 1) will select aluminum, calcium oxide, aluminum oxide, silicon dioxide and magnesium oxide to dry, pulverize and sieve in the vacuum reactor according to the mass fraction ratio to obtain the mixture;

[0044] 2) the mixture obtained in step 1) is made into granules by pressure forming and granulation, and the particle size of the granules is 5-50mm;

[0045] 3) The granules obtained in step 2) are sealed and stored in a moisture-proof bag.

[0046] Further, in step 1), the drying temperature of the vacuum reactor is 40-60° C., and the moi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com