Intelligent manufacturing device for large plate polishing production

A technology for intelligent manufacturing and sheet materials, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, manufacturing tools, etc., can solve the problems of low automation, grinding processing efficiency, inconvenient plant design layout, time-consuming and energy-consuming, etc., to achieve Improve the efficiency of grinding and processing, facilitate the layout of dust removal equipment, and save the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

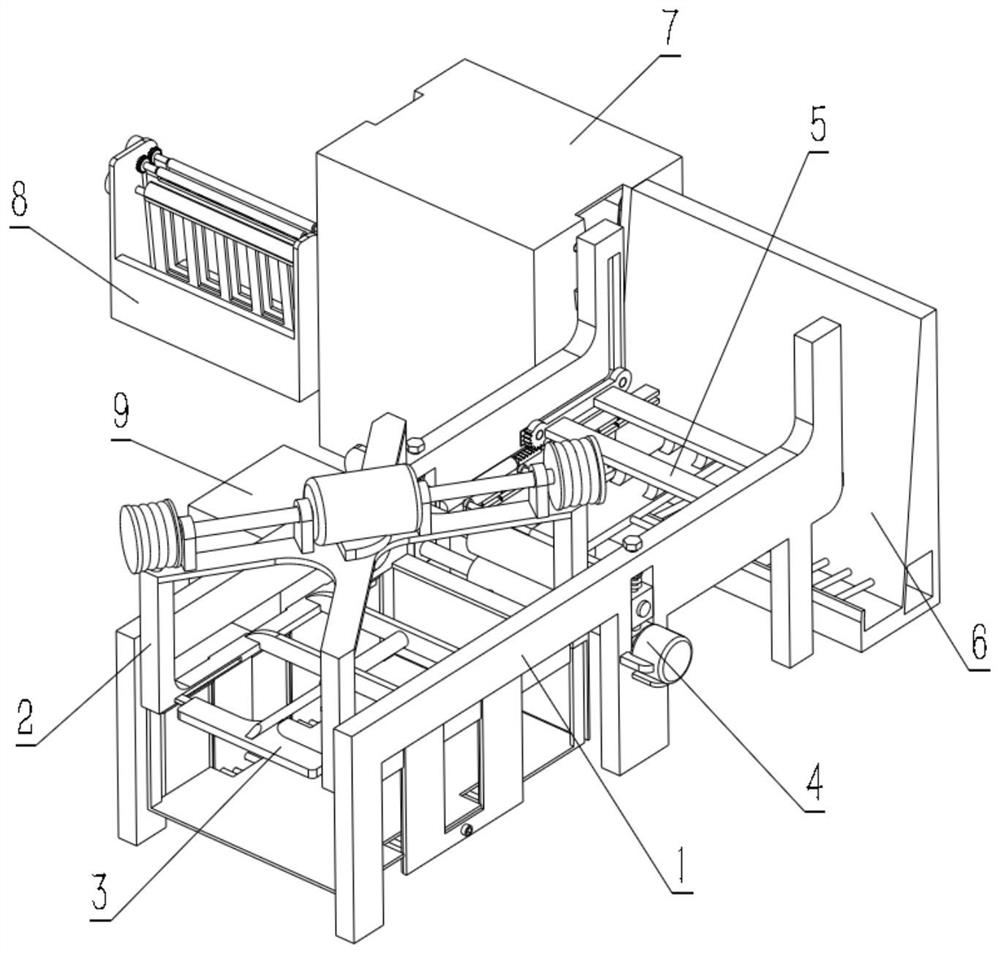

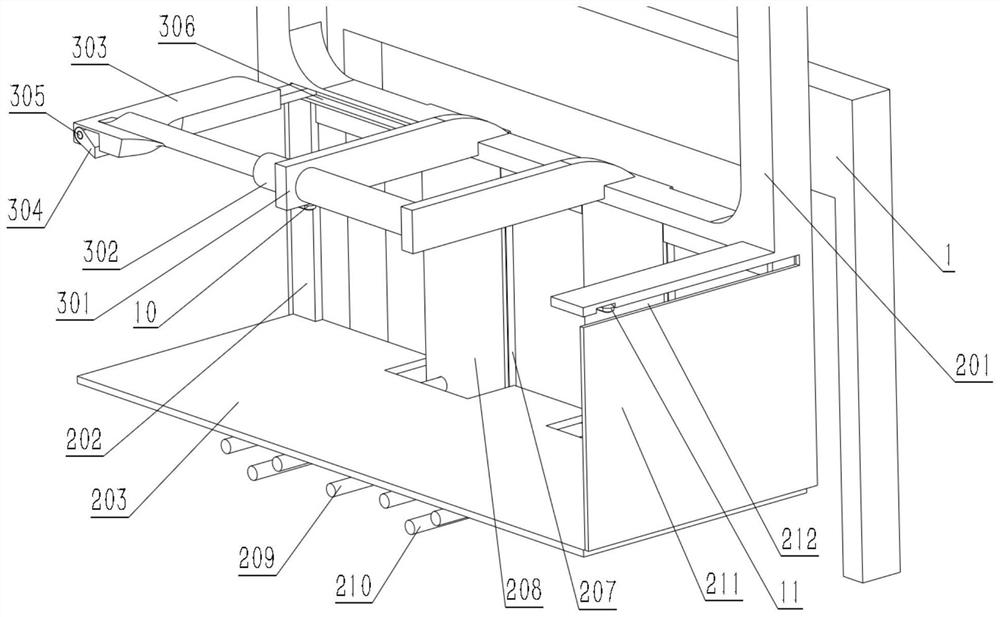

[0029] like Figure 1 to Figure 13 As shown in the figure, an intelligent manufacturing device used for the grinding and production of large plates of the present invention adopts a technical scheme that includes a main frame body 1, one end of the main frame body 1 is fixedly installed with a feeding frame 2, and the other end is installed with a turning plate Device 5, a feeding device 4 is installed on the main frame body 1 between the feeding frame 2 and the turning device 5, the plates to be processed are stacked on the feeding frame 2, and the plates are fed into the turning device one at a time through the feeding device 4. In the board device 5, the state of turning the board from horizontal to vertical is completed by it, and the feeding rack 2 includes a fixing frame 201 fixedly connected to the main frame body 1, and the vertical pipes at the four corners of the fixing frame 201 are slidably inserted into the vertical pipe. Lifting frame 202, a bottom plate 203 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com