Method for improving stable wear resistance of automobile metal casting part

A technology for metal casting and wear resistance, applied in the direction of testing wear resistance, casting equipment, casting molding equipment, etc. Wear resistance, the effect of prolonging the time of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

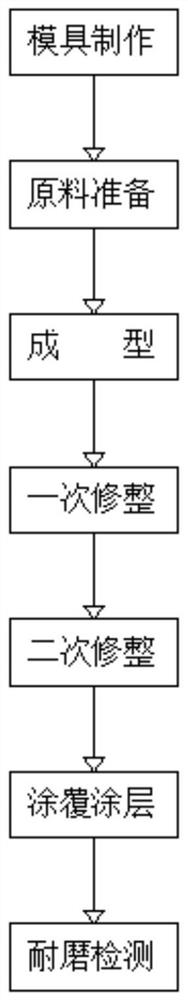

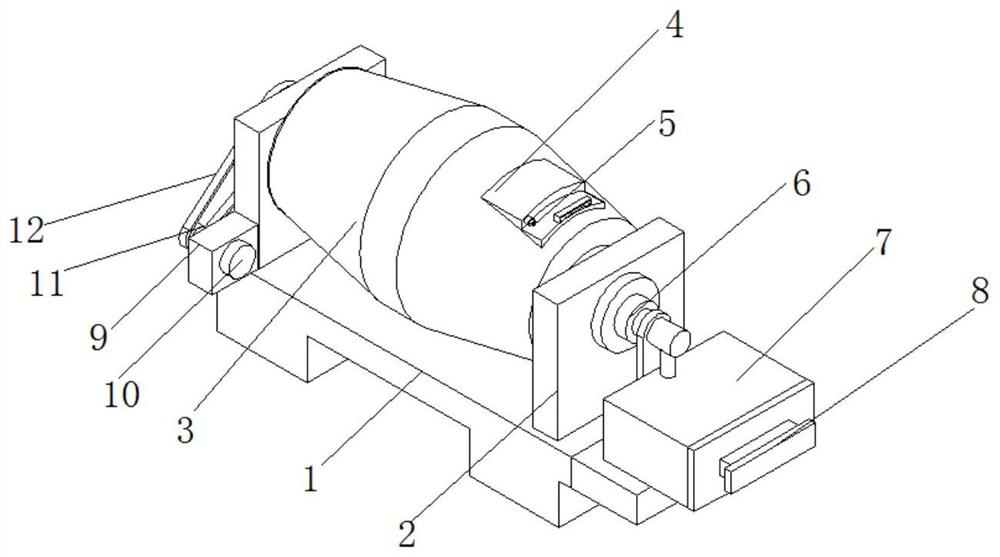

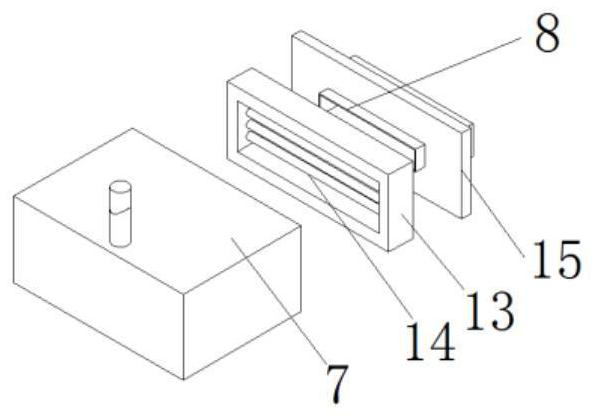

[0030] refer to Figure 1-5 , a method for improving the stable wear resistance of automotive metal castings, comprising the steps of:

[0031] S1: Mold making, design the mold according to the actual size of the metal casting, and then print out the drawings to make two molds that cooperate with each other;

[0032] S2: Raw material preparation, prepare appropriate iron ingot raw materials and clean them, polish and clean the rust on the surface of the iron ingot, then heat and melt the iron ingot to obtain molten iron, put the molten iron in the melting furnace and then put it in the melting furnace Add an appropriate amount of metal powder to obtain a mixed melt, and the temperature of the mixed melt is 1700°C;

[0033] S3: Forming, inject the mixed melt obtained above into the mold, wait for it to be formed and then cool the mold, and use the cooling equipment to assist in cooling during cooling, pay attention to the cooling range to avoid the sudden drop in temperature f...

Embodiment 2

[0042] refer to Figure 1-5 , a method for improving the stable wear resistance of automotive metal castings, comprising the steps of:

[0043] S1: Mold making, design the mold according to the actual size of the metal casting, and then print out the drawings to make two molds that cooperate with each other;

[0044] S2: Raw material preparation, prepare appropriate iron ingot raw materials and clean them, polish and clean the rust on the surface of the iron ingot, then heat and melt the iron ingot to obtain molten iron, put the molten iron in the melting furnace and then put it in the melting furnace Add an appropriate amount of metal powder to obtain a mixed melt, and the temperature of the mixed melt is 1700°C;

[0045] S3: Forming, inject the mixed melt obtained above into the mold, wait for it to be formed and then cool the mold, and use the cooling equipment to assist in cooling during cooling, pay attention to the cooling range to avoid the sudden drop in temperature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com