Impact crusher plate hammer made of high-chromium cast iron-based ZTA ceramic composite material and manufacturing method of impact crusher plate hammer

A technology of impact crusher and ceramic composite material, applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of short service life, wear, fracture, low crushing efficiency, etc. Wear-resistant, meet the effect of frequent crushing and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

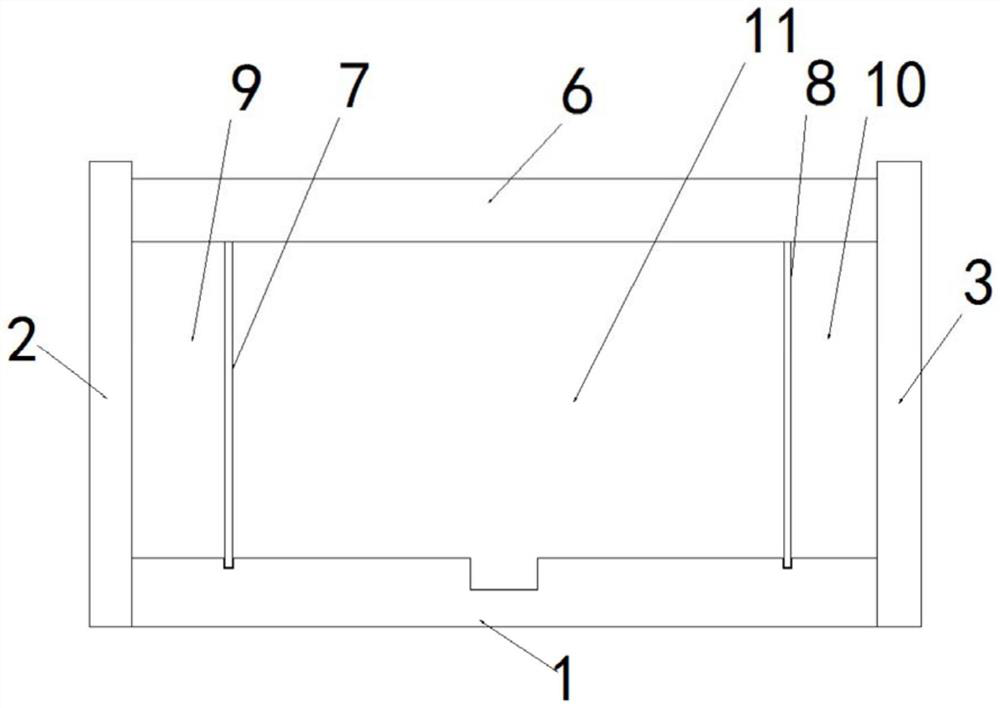

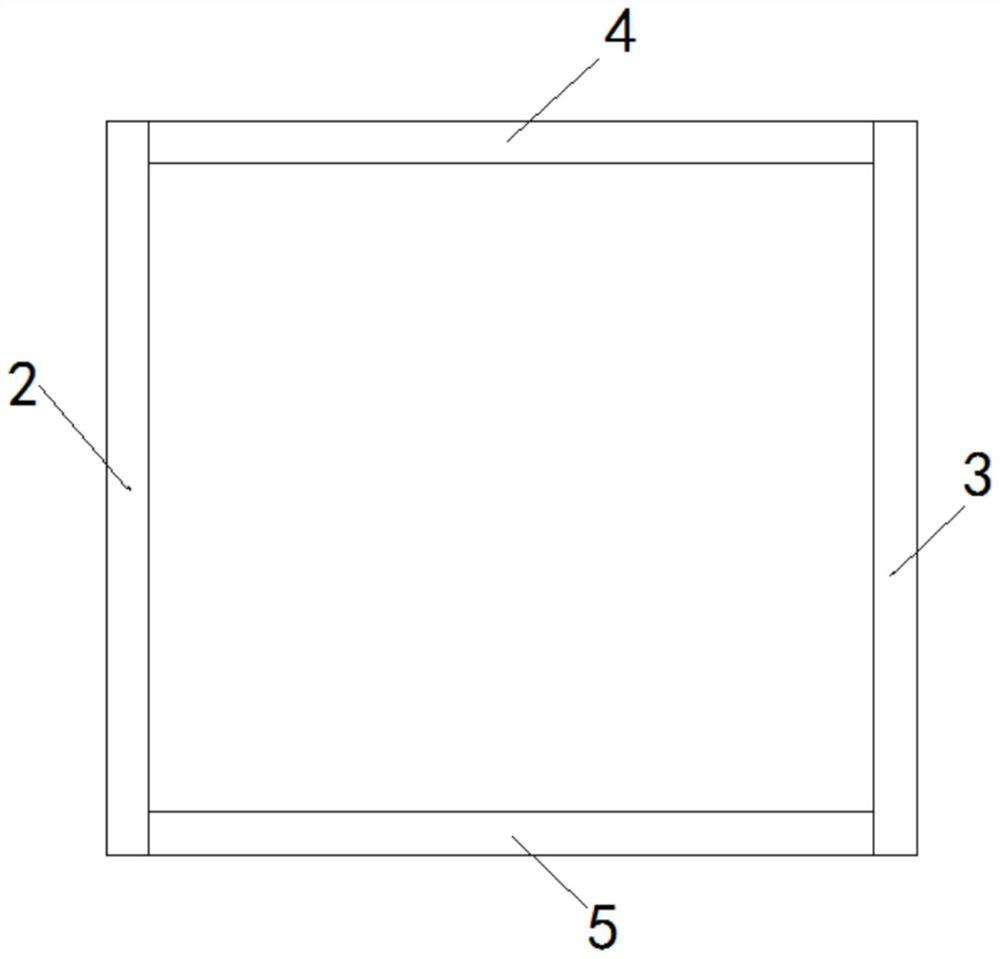

[0032] like Figure 1a and 1b As shown, the rigid metal mold used in this embodiment includes a bottom plate 1, a first side plate 2, a second side plate 3, a first plate 4, a second plate 5 and a top plate 6, a bottom plate 1, a first side plate 2, The second side panel 3 , the first panel 4 and the second panel 5 are enclosed to form a cavity, the cavity is provided with a first grid plate 7 and a first grid plate 8 , the bottom plate 1 , the first side plate 2 A first area 9 is formed between the bottom plate 1, the second side plate 3 and the second grid plate 8, a second area 10 is formed between the bottom plate 1, the second side plate 3 and the second grid plate 8, the bottom plate 1, the first grid plate 7 and the second grid plate 8 A third area 11 is formed between the grid plates 8 .

[0033] The thickness of the first grid plate 7 and the first grid plate 8 is 1 mm, the mesh hole is 2 mm, and the material is high carbon and high chromium steel.

[0034] The manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com