Anti-sinking laminating seeding machine

A seeder and film-covering technology, which is applied in the direction of fertilizers and seeding equipment, agricultural machinery and equipment, plant protection covers, etc., can solve the problems of low flatness of the film, tearing, and subsidence of the film-covered planter, so as to reach the sowing position Accurate, flat and tight film covering, remarkable effects of drought resistance and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

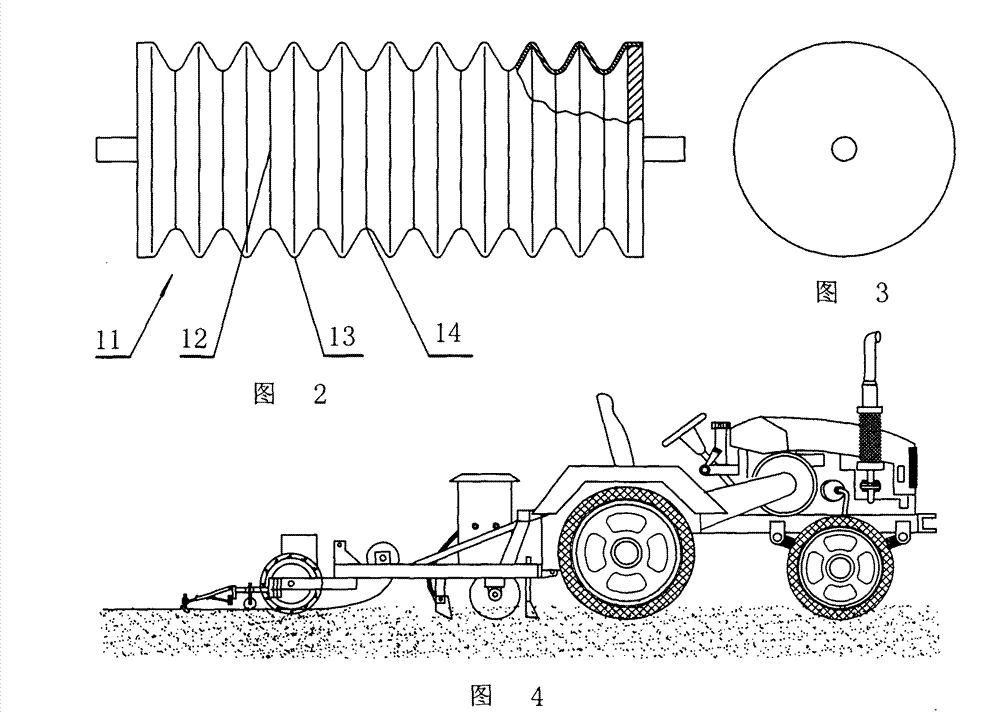

[0034] The general idea of the present invention is to assemble a corrugated drum at the front of the seeding and covering machine, press and build a plurality of convex ribs on the ground, enhance the compressive strength of the ground, prevent the equipment from sinking into the soil, and realize the smooth and fast film covering and sowing operation. Around this idea, four implementations are introduced below:

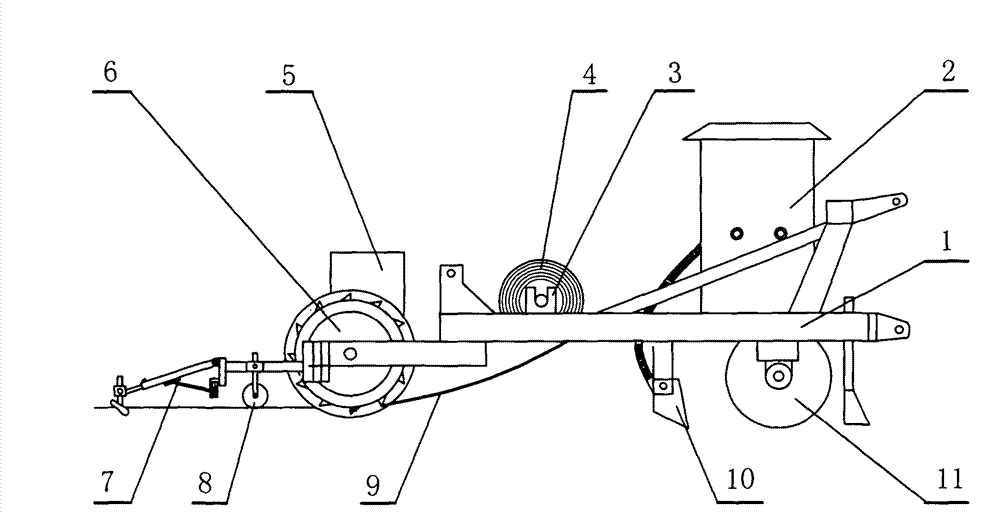

[0035] The first embodiment: as figure 1 As shown, this anti-sinking film seeder has a frame-type frame 1, and the front of the frame 1 is provided with an articulation point, and the frame 1 is equipped with a fertilizer box 2, a mulch frame 3, a seed box 5, and a seeding disc. 6. Parts such as soil covering plate 7, film pressing wheel 8, ditching fertilizer applicator 10, etc. The mulching film reel 4 is installed above the mulching film stand 3, and the mulching film 9 rolls on the mulching film reel 4. The most outstanding feature of this implement is: a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com