Mixer assembly

A mixer and assembly technology, applied in the direction of machines/engines, charging systems, combustion engines, etc., can solve the problems of large differences in the air-fuel ratio of the mixed gas in each cylinder of the engine, uneven mixing of various gases, and reduced engine performance. , to achieve the effect of ensuring the uniformity of the concentration, preventing the discharge from exceeding the standard, and improving the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

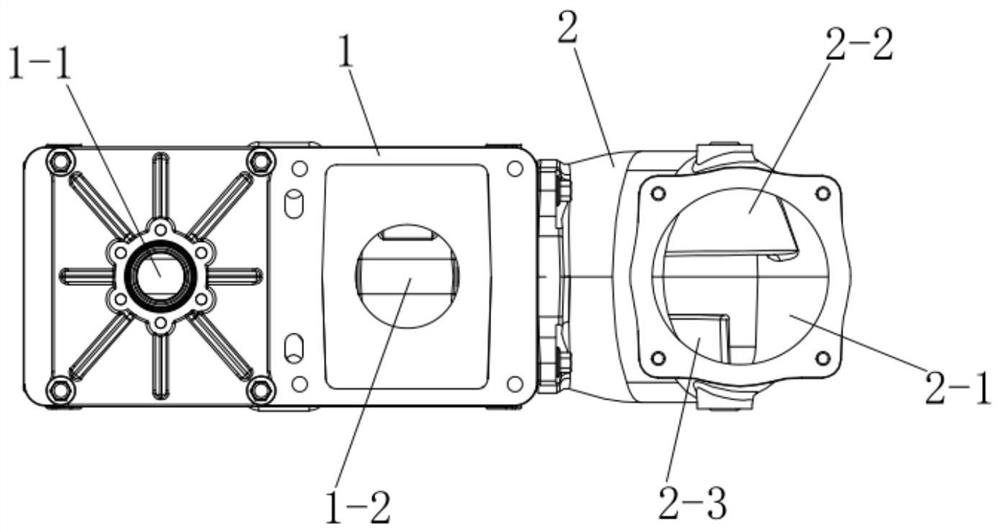

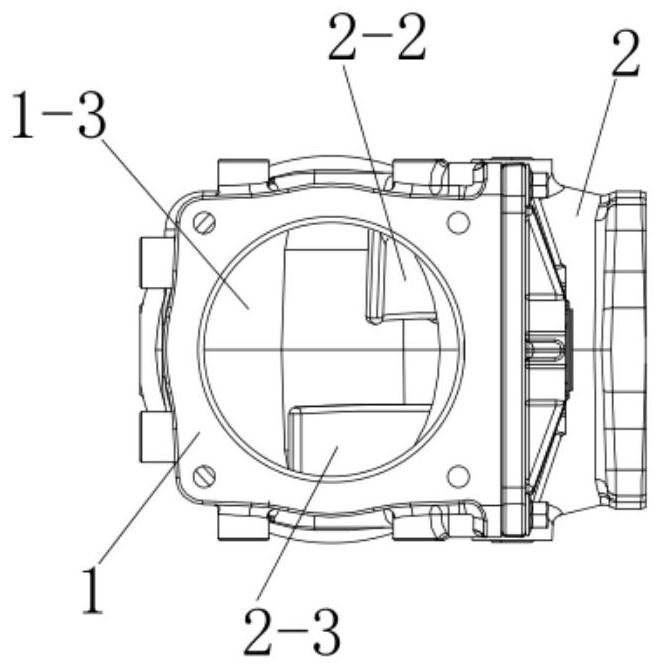

[0031] Example 1: as Figure 1-4 As shown in the figure, a mixer assembly includes a mixer 1. A mixer pipe is provided on the mixer 1. The mixer pipe runs through the left end face and the right end face of the mixer 1. The pipe opening on the left end face of the mixer 1 is Mixed gas outlet, the pipe port on the right end face of the mixer 1 is the mixed gas inlet, the front end face of the mixer 1 is provided with two air inlets, the air inlet on the right side of the front end face of the mixer 1 is the EGR inlet 1-2, The air inlet on the left side of the front end face of the mixer 1 is the gas inlet 1-1, the right end face of the mixer 1 is provided with a mixer nozzle, and the mixer nozzle is provided with a flow guide structure.

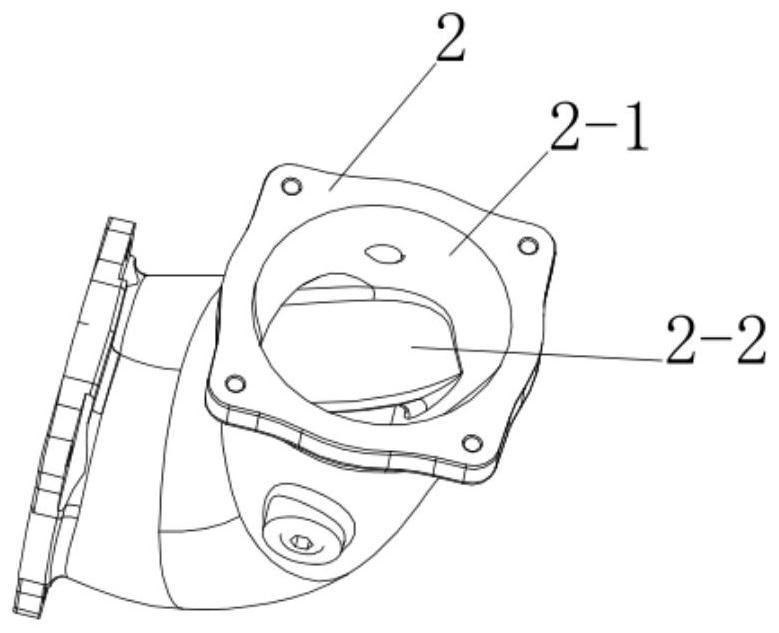

[0032] The mixer nozzle is the elbow mixer nozzle 2, the bottom surface of the bending part inside the elbow mixer nozzle 2 is provided with a vertical lower guide structure 2-3, and the bending part inside the elbow mixer nozzle 2-3 The top ...

Embodiment 2

[0033] Example 2: as Figure 2-6 As shown, in this embodiment, the structure of the mixer is the same as that of Embodiment 1, wherein the mixer nozzle is a straight-tube mixer nozzle 3, and the interior of the straight-tube mixer nozzle 3 is provided with several sidewall guide structures 3-1 , the side wall guide structure 3-1 is a blade structure, and the side wall guide structure 3-1 is reduced from the right end to the left end to form an elongated blade structure.

[0034] A rotating fan blade can also be arranged in the nozzle of the mixer.

[0035] Working principle: Before the air takes over from the mixer to enter the mixer 1, the air passes through the upper diversion structure 2-2 and the lower diversion structure 2-3 or the side wall diversion structure 3-1 to disturb the disturbance. In the mixer 1, the EGR inlet 1- The EGR exhaust gas is introduced into 2 places, and the gas is introduced into the gas inlet 1-1. When the air reaches the mixer 1, it is in a turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com