Prestressed concrete cover beam based on prefabricated prestressed UHPC (Ultra High Performance Concrete) shell and construction process of prestressed concrete cover beam

A concrete and prestressed technology, which is applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of difficult transportation and hoisting of cover beams, difficulties, and heavy cover beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

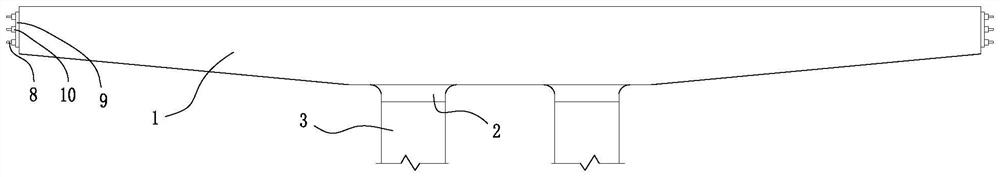

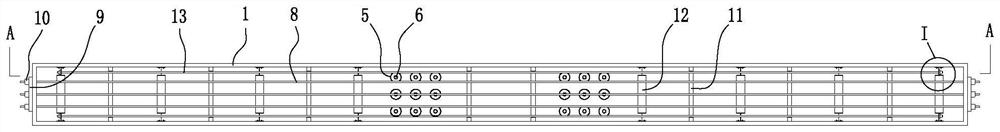

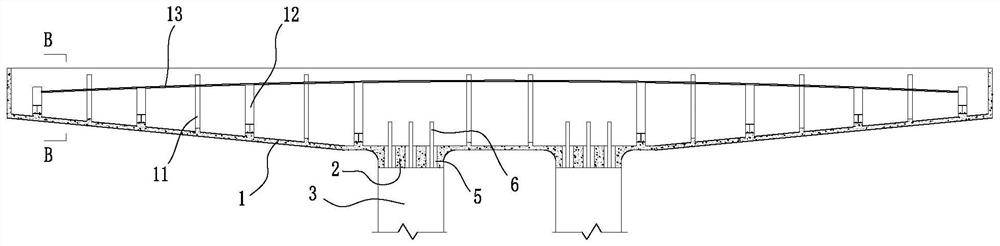

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] like Figure 1~6 As shown, a prestressed concrete cover beam based on a prefabricated prestressed UHPC shell, including a UHPC shell 1, a support 2, a pier column 3, a steel skeleton 4, a concrete rib 11, an I-shaped steel rib 12 and a prestressed steel bar 13; The UHPC shell 1 is arranged on the top of the pier 3 through the support 2; the UHPC shell 1 and the support 2 adopt an integrated structure, and several pre-embedded casings 5 are vertically arranged on the support 2; The top of the column 3 is vertically provided with several pre-embedded steel bars 6, the number of the pre-embedded steel bars 6 is the same as that of the pre-embedded sleeves 5 and their positions correspond one by one, and the pre-embedded steel bars 6 pass through the pre-embedded sleeves 5 and extend to the inside of the UHPC shell 1; The steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com