Preparation method and application of rare earth cerium doped nickel sulfide/iron sulfide heterojunction material

A technology of nickel sulfide and iron sulfide, applied in the field of electrocatalysis, to achieve the effects of improving oxygen mobility, improving mass transfer efficiency, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

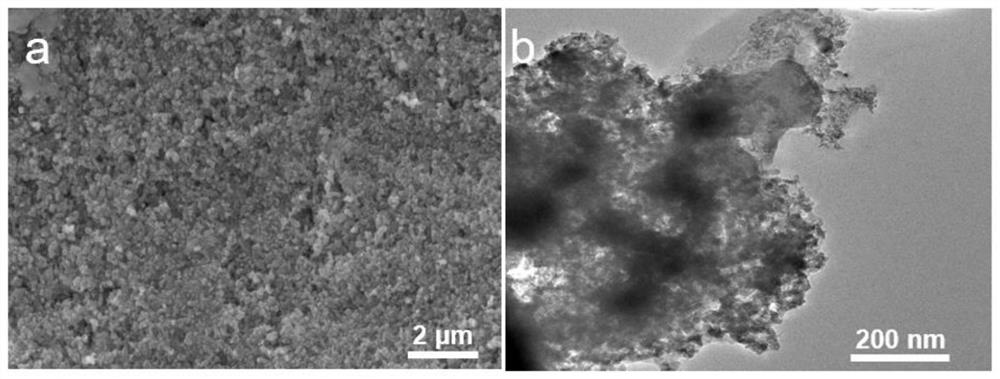

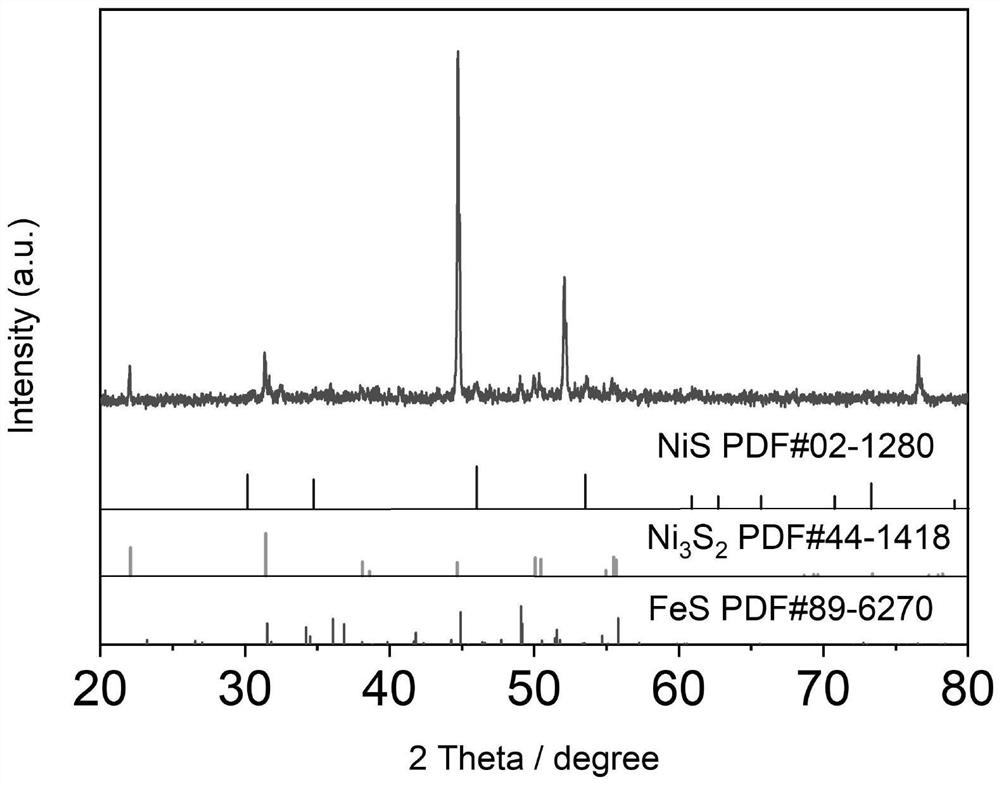

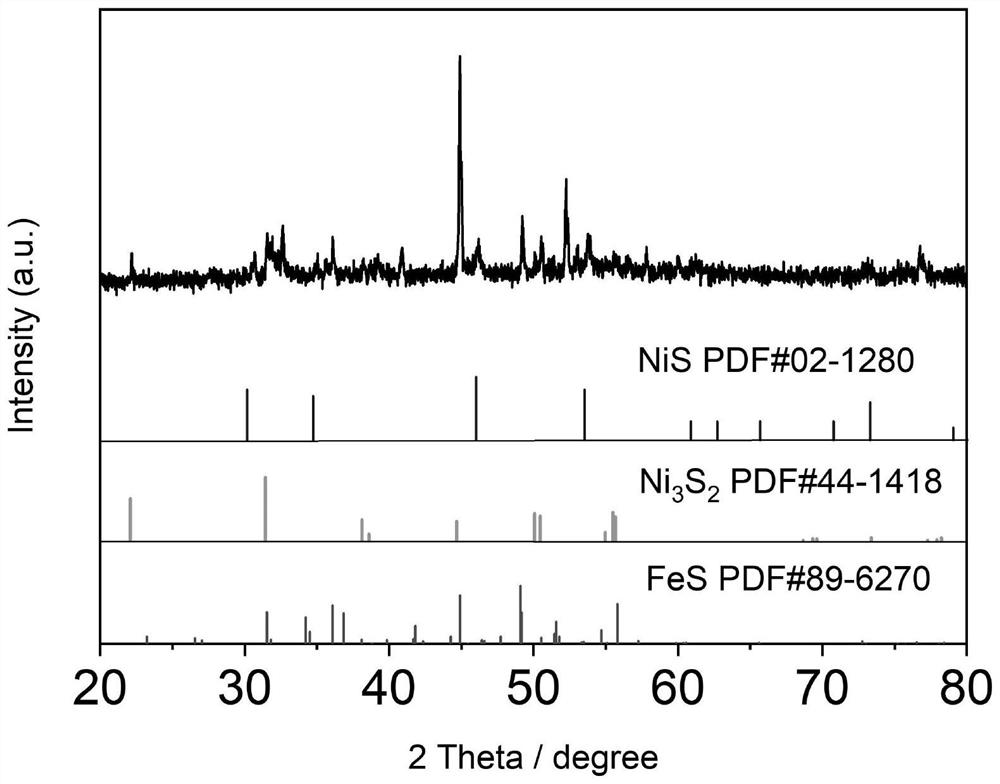

Image

Examples

Embodiment 1

[0028] (1) Preparation of precursor solution: Weigh 3.489g of nickel nitrate hexahydrate (12mmol) into a 100mL glass beaker, then weigh 1.212g of iron nitrate hexahydrate (3mmol) into the beaker, and finally weigh 0.043g Cerium nitrate hexahydrate (0.1 mmol) was added to the above 100 mL beaker. Use a graduated cylinder to measure 100mL of deionized water into a 100mL beaker, put in a magnet, put the beaker on a magnetic stirrer, and stir magnetically for 20 minutes at room temperature to dissolve into a uniform solution;

[0029] (2) Treatment of nickel foam

[0030] Place 1cm X 1.5cm, 0.5mm thick nickel foam in 3moL / L hydrochloric acid for 10min to remove the oxide layer, then rinse with deionized water and ethanol, and dry.

[0031] (3) Preparation of Ce-NiFeLDH / NF

[0032] A clean nickel foam was used as the working electrode, a graphite rod was used as the counter electrode, and Ag / AgCl (saturated KCl solution) was used as the reference electrode. Then, immerse the thr...

Embodiment 2

[0037] (1) Preparation of precursor solution: Weigh 3.489g of nickel nitrate hexahydrate (12mmol) into a 100mL glass beaker, then weigh 1.212g of iron nitrate hexahydrate (3mmol) into the beaker. Use a measuring cylinder to measure 100mL of deionized water into a 100mL beaker, put in a magnet, put the beaker on a magnetic stirrer, and stir magnetically for 20 minutes at room temperature to dissolve into a uniform solution;

[0038] (2) Treatment of nickel foam

[0039] Place 1cm X 1.5cm, 0.5mm thick nickel foam in 3moL / L hydrochloric acid for 10min to remove the oxide layer, then rinse with deionized water and ethanol, and dry.

[0040] (3) Preparation of NiFeLDH / NF

[0041] A clean nickel foam was used as the working electrode, a graphite rod was used as the counter electrode, and Ag / AgCl (saturated KCl solution) was used as the reference electrode. Then, immerse the three electrodes in the precursor solution of step (1), carry out constant current sinking at -20mA for 900s...

Embodiment 3

[0046] (1) Preparation of precursor solution: Weigh 3.489g of nickel nitrate hexahydrate (12mmol) into a 100mL glass beaker, then weigh 1.212g of iron nitrate hexahydrate (3mmol) into the beaker, and finally weigh 0.043g Cerium nitrate hexahydrate (0.1 mmol) was added to the above 100 mL beaker. Use a measuring cylinder to measure 100mL of deionized water into a 100mL beaker, put in a magnet, put the beaker on a magnetic stirrer, and stir magnetically for 20 minutes at room temperature to dissolve into a uniform solution;

[0047] (2) Treatment of nickel foam

[0048] Place 1cm X 1.5cm, 0.5mm thick nickel foam in 3moL / L hydrochloric acid for 10min to remove the oxide layer, then rinse with deionized water and ethanol, and dry.

[0049] (3) Preparation of Ce-NiFeLDH / NF

[0050] A clean nickel foam was used as the working electrode, a graphite rod was used as the counter electrode, and Ag / AgCl (saturated KCl solution) was used as the reference electrode. Then, immerse the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com