Chemical production mechanical equipment with automatic feeding function

A technology for chemical production and mechanical equipment, which is applied in the field of chemical production machinery and equipment for automatic feeding, can solve problems such as caking and labor, and achieve the effect of convenient cleaning and preventing backflow of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

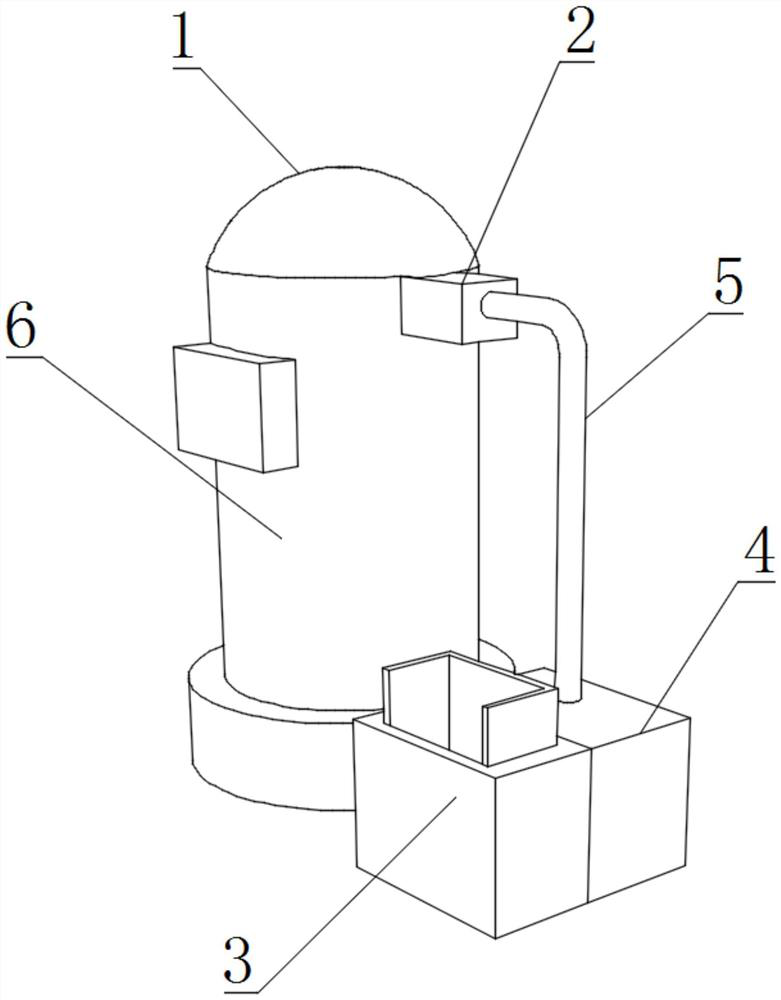

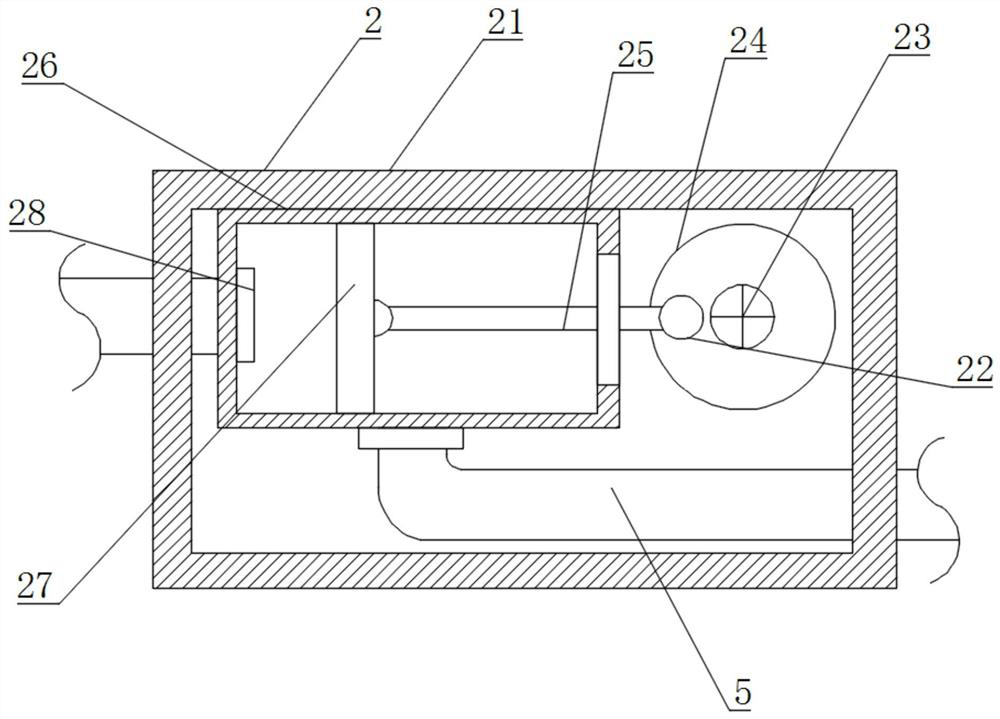

[0031] like Figure 1-6 As shown, the present invention provides an automatic feeding chemical production machinery equipment, the chemical production device main body 1, the chemical production device main body 1 includes a reaction furnace 6, one side of the reaction furnace 6 is provided with a feeding pipe 5, and the side of the feeding pipe 5 is A storage box 4 is fixedly connected to one end, a grinding device 3 is arranged on one side of the storage box 4, and a feeding device 2 is fixedly connected to the other end of the feeding pipe 5. The feeding device 2 includes a fixed box 21, and the inner wall of the fixed box 21 is fixedly connected. There is a sealing box 26, a piston 27 and a valve device 28 are arranged inside the sealing box 26, and the grinding device 3 includes a crushing box 31. The top of the crushing box 31 is provided with a feeding hole, and the inner wall of the crushing box 31 is movably connected with a grinding disc two. 33. One side of grinding...

Embodiment 2

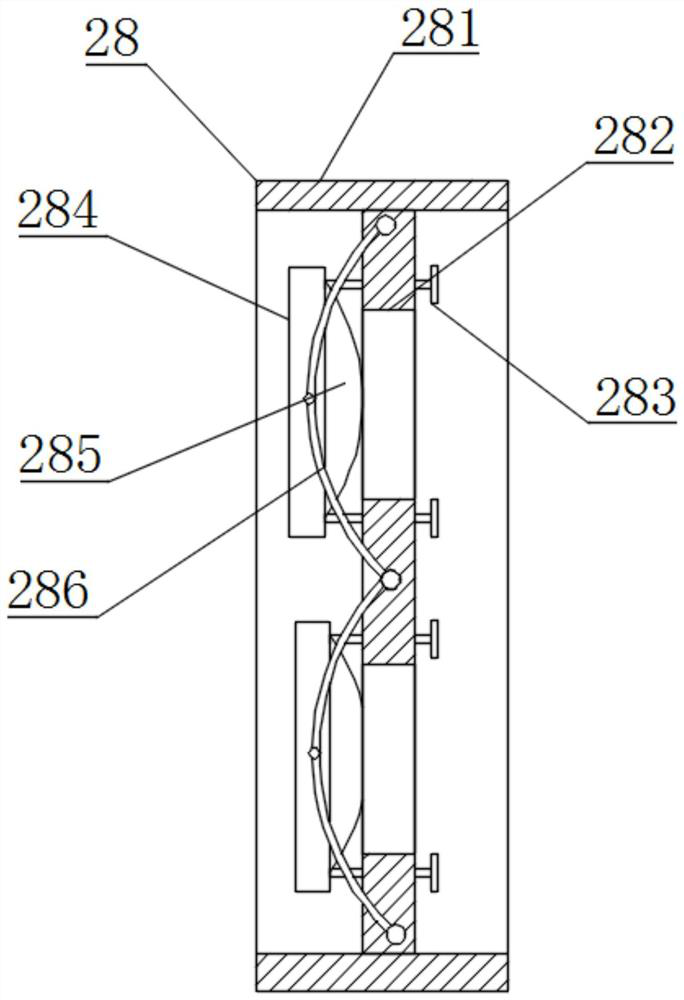

[0033] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the valve device 28 includes a fixed pipe 281, the inner wall of the fixed pipe 281 is fixedly connected with a fixed rod 282, and the interior of the fixed rod 282 is provided with A water hole, a moving rod 283 is movably connected to the inside of the fixed rod 282, one end of the moving rod 283 is fixedly connected with a movable column 284, one side of the movable column 284 is fixedly connected with an elastic pad 285, and the other side of the movable column 284 is fixedly connected There is an elastic ring 286, one side of the elastic ring 286 is fixedly connected with the outer wall of the fixed rod 282, and the moving rod 283 is used to move. The fixed rod 282 is closed to prevent the backflow of the materials, and the chemical materials at the bottom are automatically drawn into the interior of the reaction furnace 6, which reduces the tim...

Embodiment 3

[0035] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the inner wall of the preferred crushing box 31 is fixedly connected with a second motor 34, and the output shaft of the second motor 34 is fixedly connected with a rotating rod 35, The outer wall is fixedly connected with the inner wall of the second grinding plate 33, one side of the second grinding plate 33 is movably connected with one side of the first grinding plate 32, the bottom of the second grinding plate 33 is provided with a discharge pipe 36, and the transmission device 37 is arranged on one side of the first grinding plate 32, The transmission device 37 includes a casing 371, the inner wall of the casing 371 is movably connected with a gear one 372, one side of the gear one 372 is fixedly connected with one end of the rotating rod 35, and the outer wall of the rotating rod 35 is movably connected with a rotating rod 374. One end is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com