All-fiber single-frequency pulse laser

A pulsed laser and single-frequency laser technology, applied in the field of lasers, can solve problems such as poor environmental stability, mechanical damage to optical fibers, and sensitivity to applied stress, and achieve the effect of improving stability, overcoming the limitation of working wavelength, and avoiding strict requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

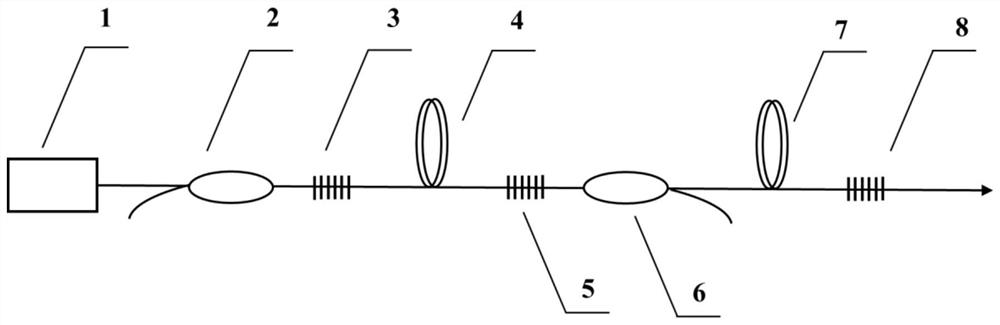

[0042] The embodiment of the present invention provides an all-fiber single-frequency pulsed laser, the laser includes: a pump source 1, a first wavelength division multiplexer 2, a first high-reflection fiber grating 3, an erbium-doped fiber 4, a first low The reflectivity fiber grating 5 , the second wavelength division multiplexer 6 , the thulium-doped fiber 7 , and the second low reflectivity fiber grating 8 .

[0043] Among them, the pump source 1 is a single-mode fiber-coupled semiconductor laser with a center wavelength of 980nm; the first wavelength division multiplexer 2 is a 980nm / 1550nm wavelength division multiplexer; the center wavelength of the first high-reflection fiber grating 3 is 1550nm, the reflectivity is >99%, the reflection bandwidth is 0.3nm; the absorption coefficient of the erbium-doped fiber 4 at 980nm is 100dB / m, and the length is 2.5cm; the center wavelength of the first low-reflection fiber grating 5 is 1550nm, and the reflectivity is 60%, and the...

Embodiment 2

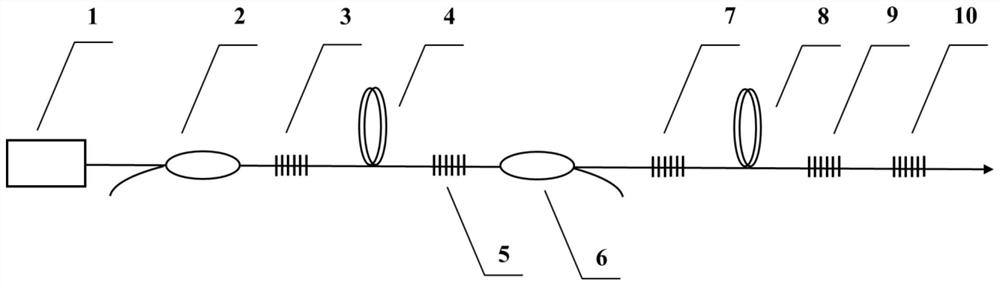

[0048] The embodiment of the present invention provides an all-fiber single-frequency pulsed laser, the laser includes: a pump source 1, a first wavelength division multiplexer 2, a first high-reflection fiber grating 3, an erbium-doped fiber 4, a first low The reflectivity fiber grating 5 , the second wavelength division multiplexer 6 , the third low reflectivity fiber grating 7 , the thulium-doped fiber 8 , the second high reflectivity fiber grating 9 and the second low reflectivity fiber grating 10 .

[0049] Among them, the pump source 1 is a single-mode fiber-coupled semiconductor laser with a center wavelength of 980nm; the first wavelength division multiplexer 2 is a 980nm / 1550nm filter-type wavelength division multiplexer; the center of the first high-reflection fiber grating 3 The wavelength is 1550nm, the reflectivity is >99%, and the reflection bandwidth is 0.3nm; the absorption coefficient of the erbium-doped fiber 4 at 980nm is 40dB / m, and the length is 0.5m; the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com