Button cell and surface treatment process of cap of button cell

A button battery, cap technology, applied in the direction of battery cover/end cover, battery pack parts, battery box/jacket, etc., can solve the problem of battery placement space, greatly increased corrosion resistance requirements, positive electrode metal prone to electrical corrosion, energy It is difficult to increase the density and other problems, so as to achieve the effect of simple and exquisite design, reducing the volume and improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

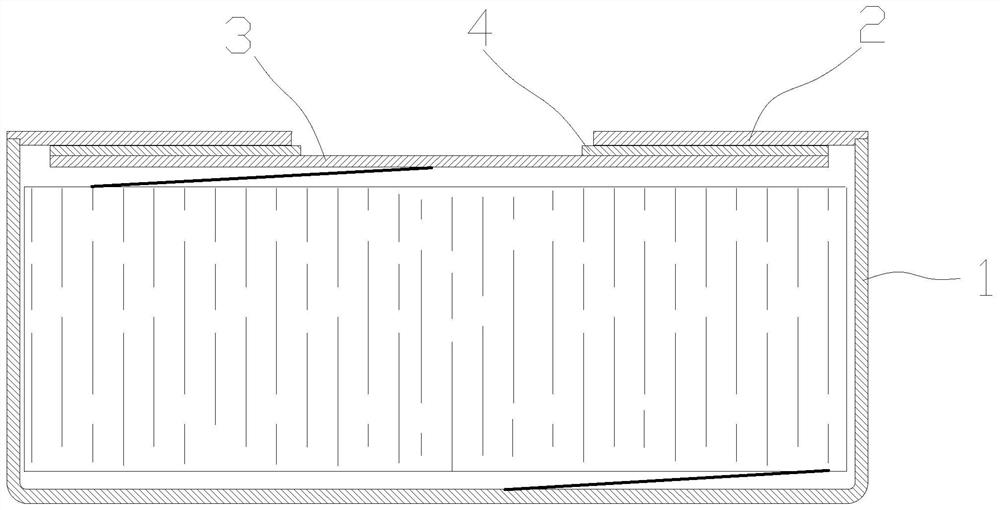

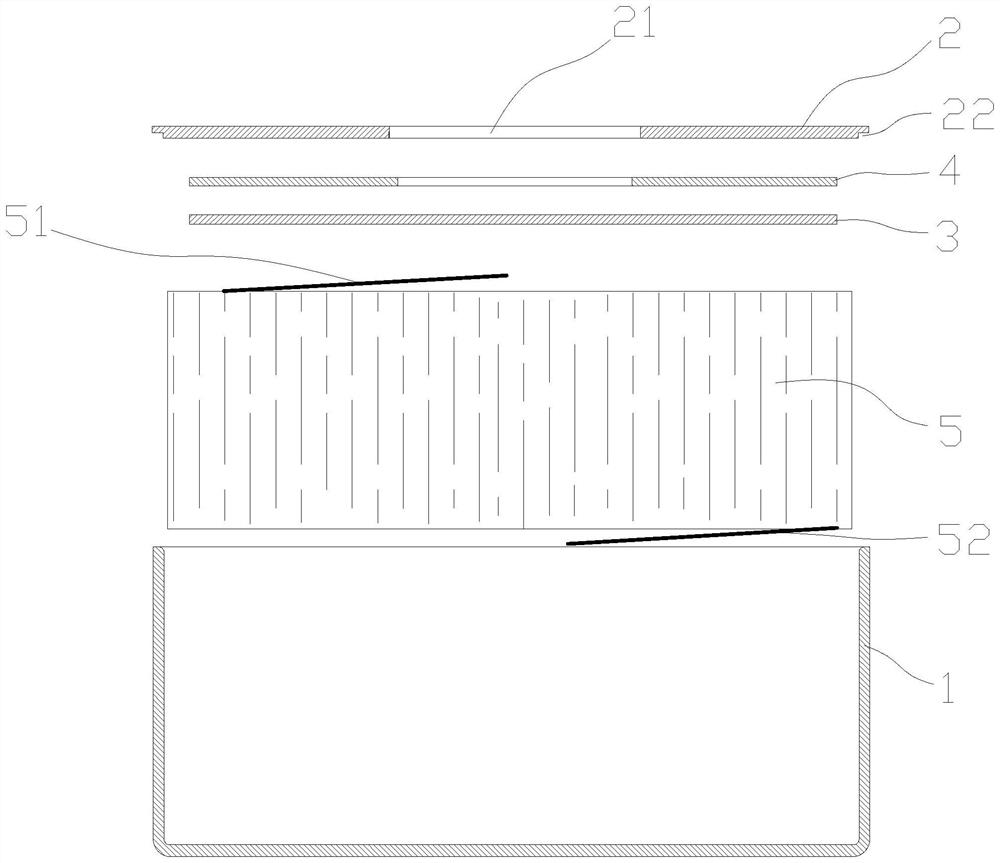

[0034] Example: Reference Figure 1-3 , the present invention mainly aims at some problems such as small capacity or specific energy density of the existing button battery, no explosion-proof function, poor corrosion resistance, short service cycle, etc., and provides a button battery, such as figure 1 As shown, the button battery includes a shell 1 with a bottom surface and a side wall extending around the edge of the bottom surface. The shell 1 is made of stainless steel. In this embodiment, the shell 1 is a cylindrical structure with an open upper end, and the single-wall thickness is 0.1 --0.25mm, the upper edge of the shell 1 is connected with a cap to form a hollow cavity.

[0035] The cap includes a connecting ring 2 with a through hole 21 in the middle and an electrode sheet 3 connected to the surface wall of the connecting ring 2 through a sealing insulating glue 4 and used to cover the through hole 21. The connecting ring 2 is welded with the upper edge of the casing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com