Spinning digital twin architecture system and implementation method thereof

A realization method, a twinning technology, applied in the direction of electrical digital data processing, digital data information retrieval, manufacturing computing system, etc., can solve the problems of unstable yarn quality, large dispersion of raw material quality, difficult to control, etc., and achieve improved yarn quality. The effect of production quality, improvement of production automation and improvement of labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with specific embodiments.

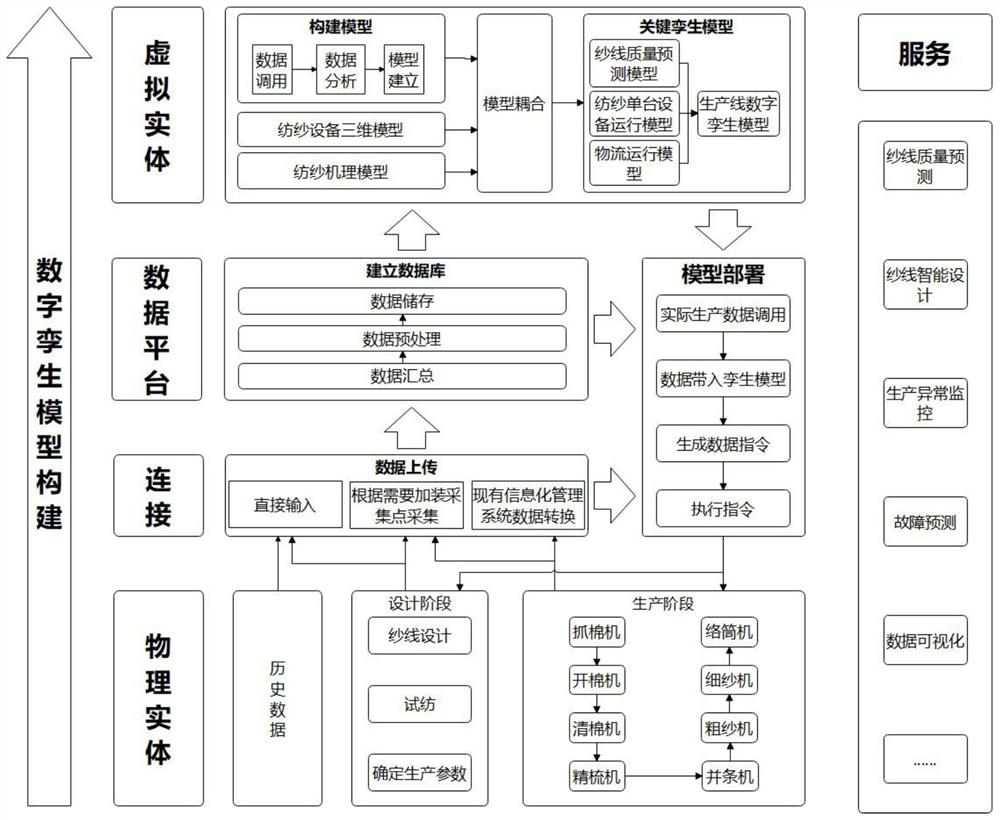

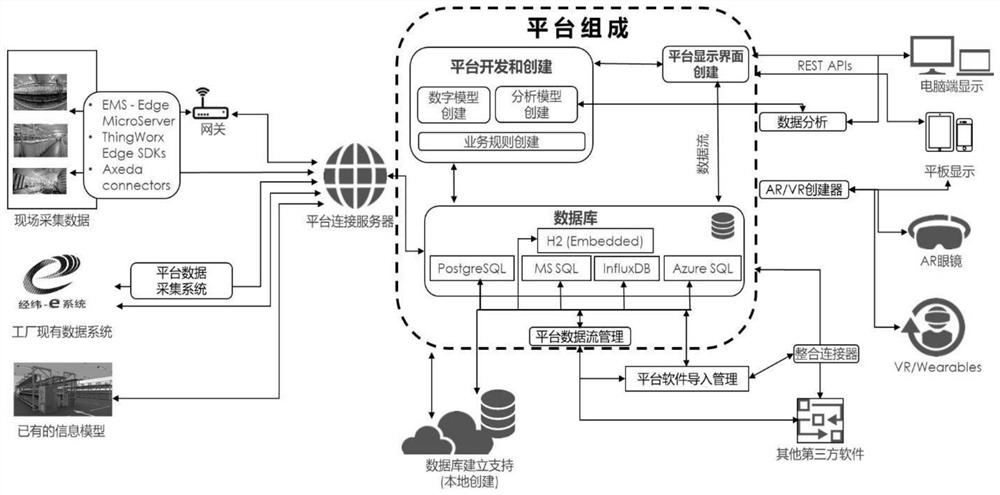

[0035] as Figure 1 As shown, a spinning digital twin architecture system, according to the definition of digital twins and the actual production of spinning production, including the physical entity, connection, data platform, virtual entity and model deployment of five parts, according to the different characteristics of the five parts to take the corresponding method to achieve the corresponding function.

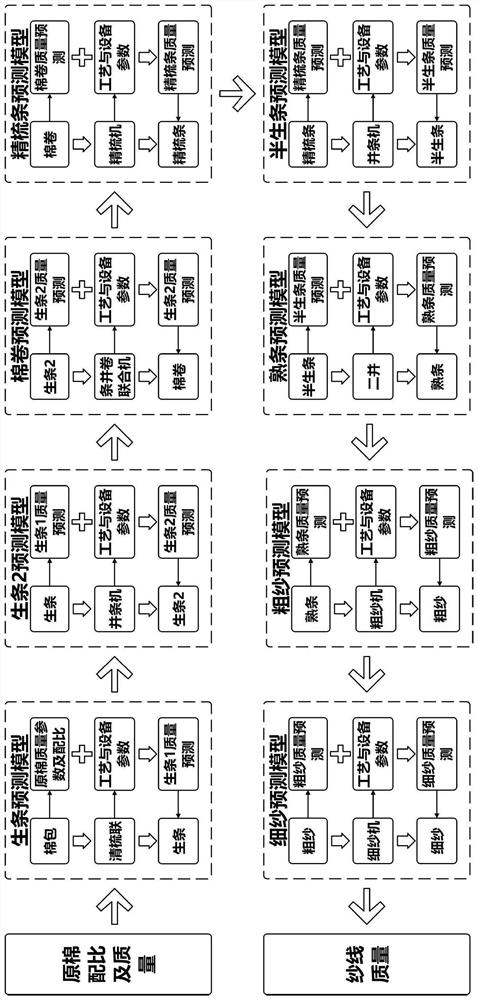

[0036] Among them, the construction and deployment methods of spinning digital twin architecture system, data platform functional architecture and three key sub-models can improve the efficiency of yarn design, improve the quality of yarn production, and increase the stability of yarn quality production to a certain extent.

[0037] The physical entity includes historical data, the design phase and the production phase, the design phase includes yarn design, trial spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com