Dosing system and method based on floc feature monitoring and process feedback

A technology of dosing system and flocculation process, which is applied to controllers with specific characteristics, control/regulation systems, control/manipulation systems, etc. It can solve the problem of excessive dosing of phosphorus removal chemicals, insufficient consideration of comprehensive feedback, and lack of core algorithms Self-adjustment and optimization feedback self-learning ability and other issues, to achieve real-time dynamic self-adjustment, predictive calculation more complex real and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

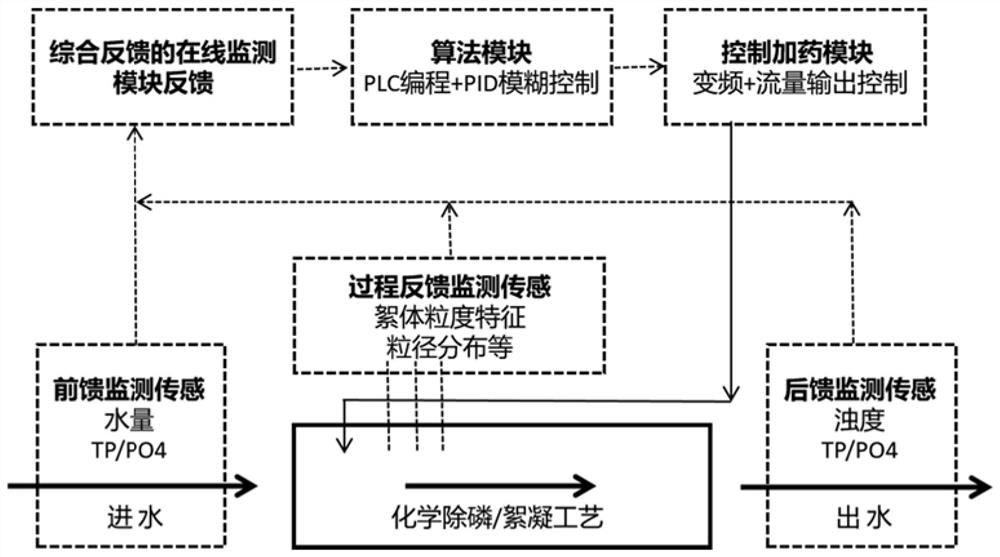

[0056] Example 1: Dosing system based on floc particle size characteristic monitoring and process feedback

[0057] see figure 1 As shown, a dosing system based on floc particle size characteristic monitoring and process feedback of the present embodiment includes a water quality monitoring module, a floc particle size characteristic monitoring module, a digital-analog analysis module, a calculation module and a dosing control module, The output ports of the water quality monitoring module and the floc particle size characteristic monitoring module are electrically connected to the input port of the digital-analog analysis module, and the output port of the digital-analog analysis module is electrically connected to the input port of the calculation module. The output port of the computing module is electrically connected with the input port of the dosing control module, and the dosing control module controls the dosing of the drug into the high-density sedimentation tank thro...

Embodiment 2

[0074] Example 2: Dosing method based on floc particle size feature monitoring and process feedback

[0075] This example further demonstrates the operation method of using the dosing system based on the characteristic monitoring of floc particle size and process feedback shown in Example 1 for precise dosing of medicaments.

[0076] The following mainly takes the dosage of phosphorus removal agents as an example.

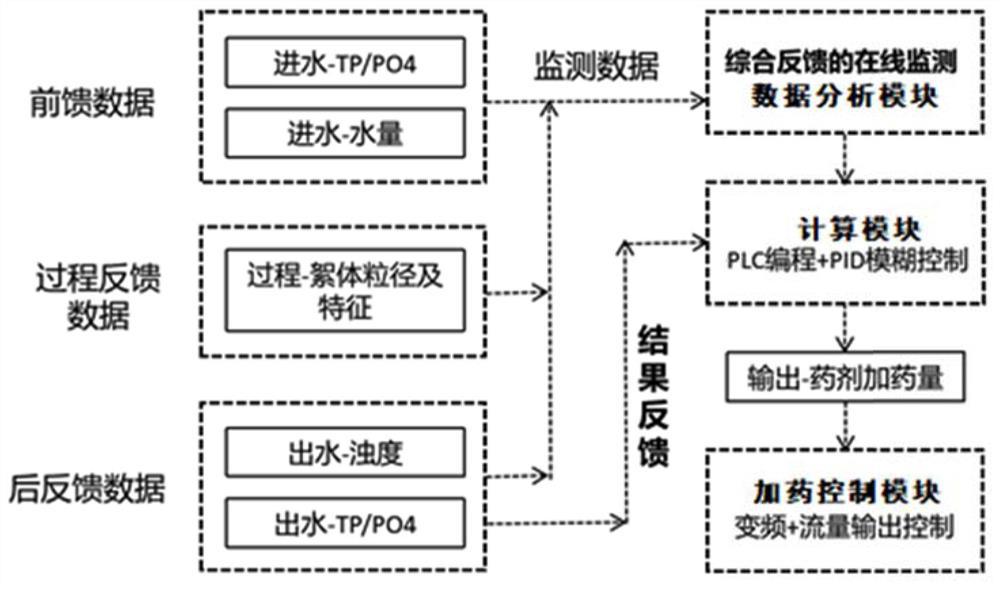

[0077] like image 3 It mainly includes the following steps:

[0078] S21, collecting the water quality online monitoring index parameters of influent and effluent or the online monitoring index parameters of floc particle size characteristics in the flocculation process respectively through the water quality monitoring module and the floc particle size characteristic monitoring module, and sending them to the digital-analog analysis module; Among them, in the process of phosphorus removal by flocculation and phosphorus removal, the particle size of flocs and the...

Embodiment 3

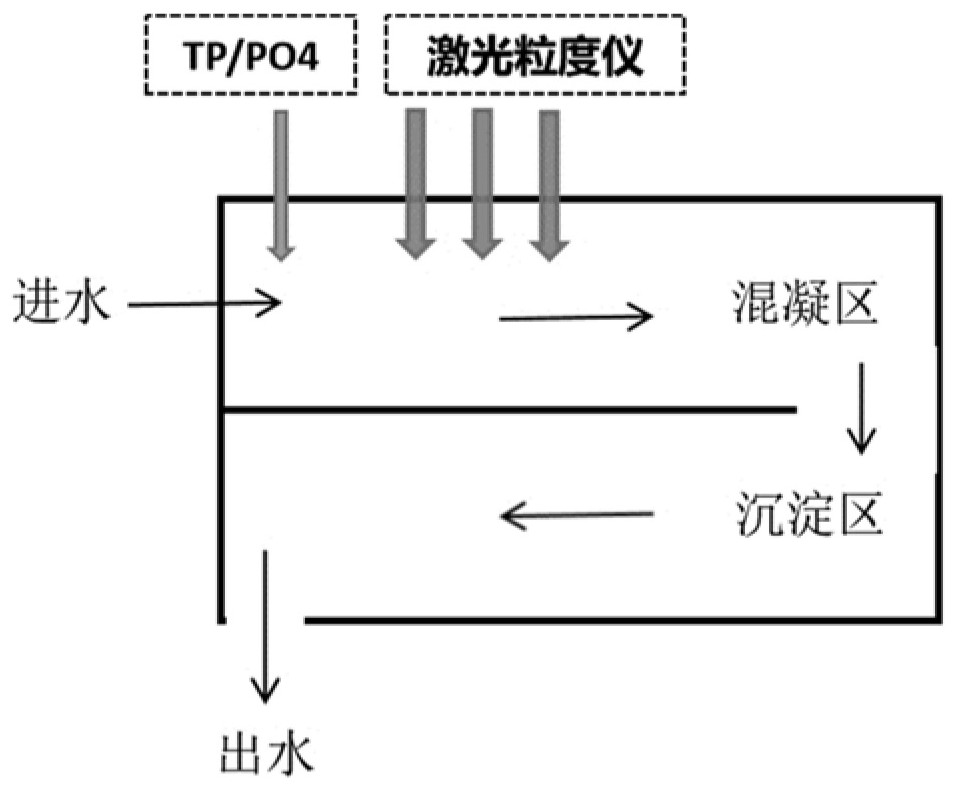

[0096] Example 3: Operation and commissioning scheme of chemical dosing system for chemical phosphorus removal based on floc particle size characteristics

[0097] First, take the influent water volume and influent TP / PO during the historical operation of the water plant manual operation. 4 Concentration, effluent TP / PO 4 The dose of the drug corresponding to the integral mean of the concentration data is the base value. Establish a trial run data idling period, that is, the data modeling process. The system is still operated manually, but all monitoring and result data are aggregated into the system module for algorithm modeling. Influent water volume, influent TP / PO during modeling using commissioning data 4 Concentration, effluent TP / PO 4 The concentration data is the basic data, and the floc particle size and distribution data of the flocculation process of phosphorus removal and flocculation are monitored online by laser particle size meter, and the turbidity of the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com