Sodium glucoheptonate solid particle drying treatment process and system

A technology of sodium glucoheptonate and solid particles, which can be used in dry cargo handling, granular material drying, solid separation, etc., and can solve the problems of inability to sell sodium glucoheptonate crystal dry powder and high moisture content of sodium glucoheptonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

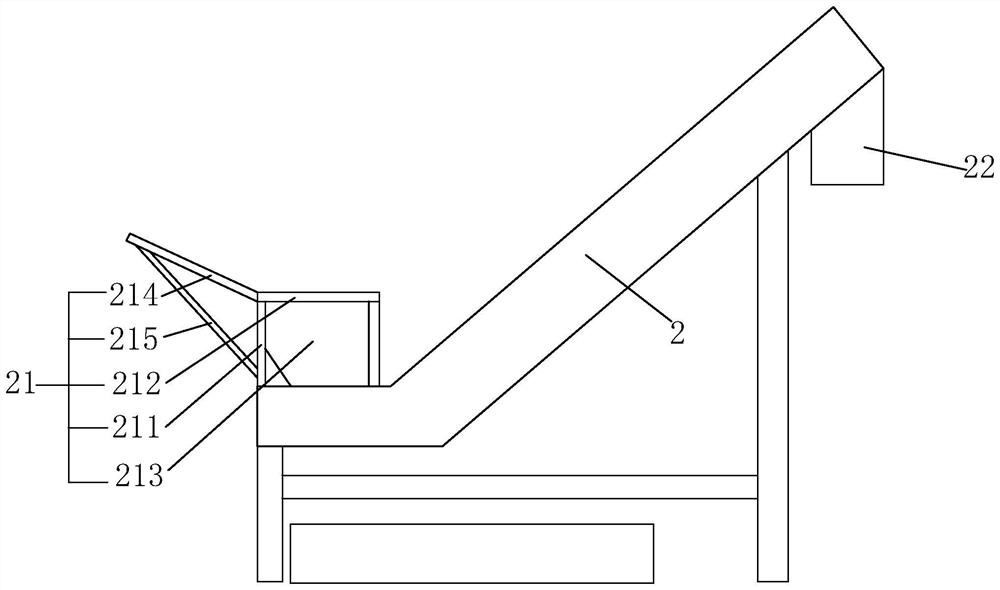

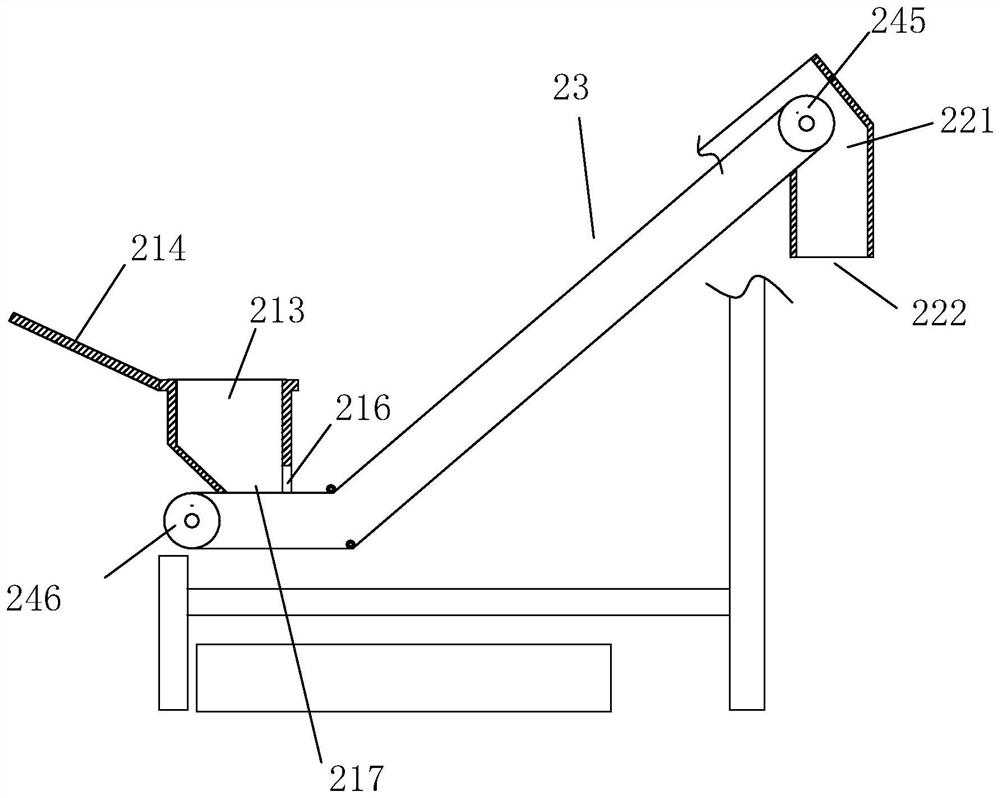

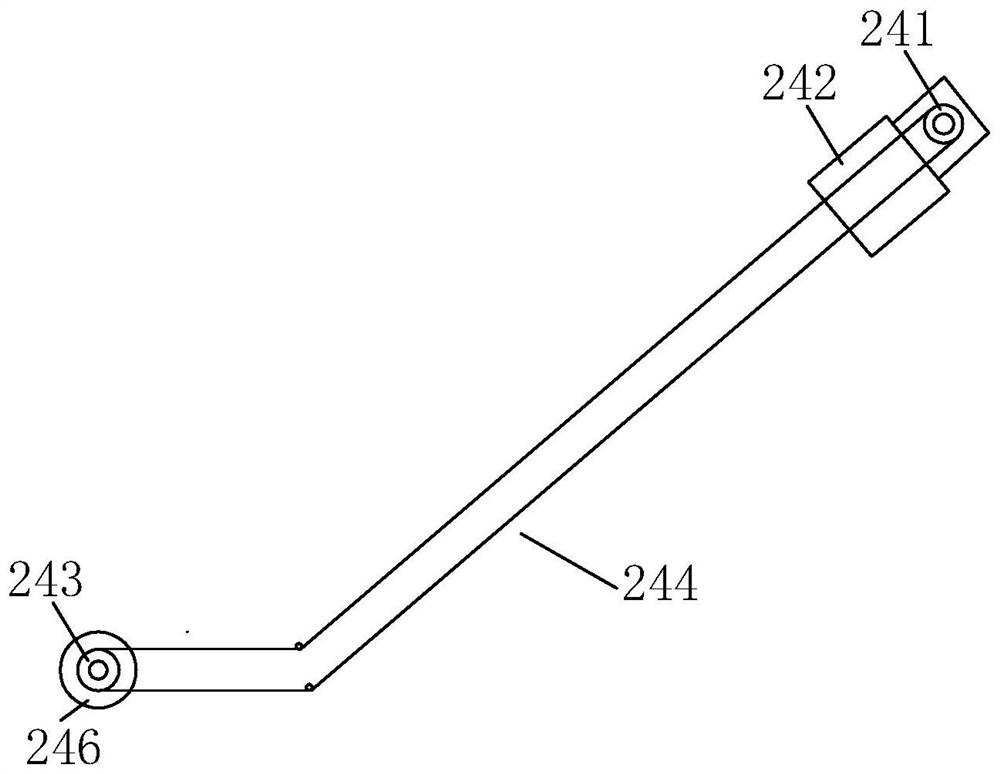

[0042] like Figure 1 to Figure 11 Shown, a kind of sodium glucoheptonate solid particle drying treatment process, comprises the following steps,

[0043] Step 1, centrifuging the sodium glucoheptonate mixture to obtain a sodium glucoheptonate solution and a solid-liquid mixture of sodium glucoheptonate, and adsorbing the sodium glucoheptonate solution by activated carbon;

[0044] In step 2, the solid-liquid mixture of sodium glucoheptonic acid is placed on the filter screen, drying steam of 60-120 degrees is passed through the bottom of the filter screen, and an air suction port is arranged above the filter screen, and the drying reaction is completed in a closed space to obtain dried glucose. For the solid particles of sodium heptonate, the filter screen is connected with a vibration motor, and the solid particles of sodium glucoheptonate on the filter screen are moved by the vibration motor. ;

[0045]Step 3, place the dried sodium glucoheptonate solid particles on at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com