Prefabricated light lattice type concrete wall assembly structure system and construction method thereof

A technology of concrete wall and assembly structure, applied in the direction of structural elements, walls, building components, etc., can solve the problems of unclear force of lattice assembly structure, difficult construction, etc., to achieve convenient construction, improve project quality, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention provides a prefabricated lightweight lattice type concrete wall assembly structure system, which aims to solve the problems existing in the past, such as unreasonable component design and many difficulties in construction.

[0048] The present invention is described in detail below through the accompanying drawings:

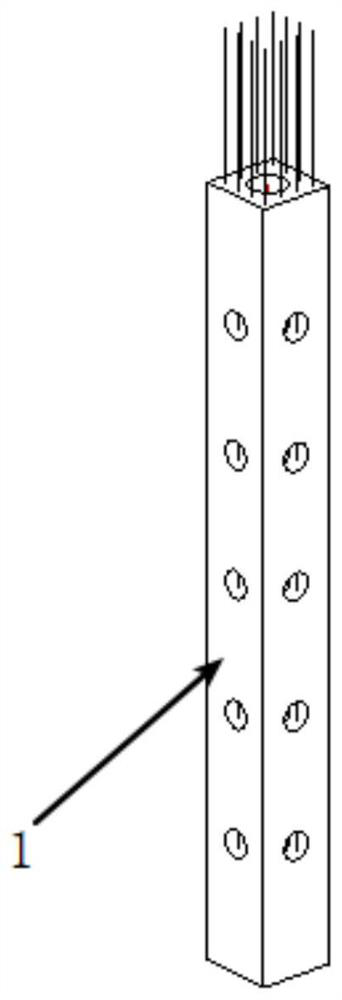

[0049] as attached figure 1 Shown: Hollow porous prefabricated column 1 is a prefabricated concrete column that is prefabricated and hollow inside, with holes evenly distributed on the sides; after it is installed on site, a solid column is formed by secondary pouring. According to the actual situation, the porous holes can be arranged in multiple lateral directions of the column, either individually or at the same time.

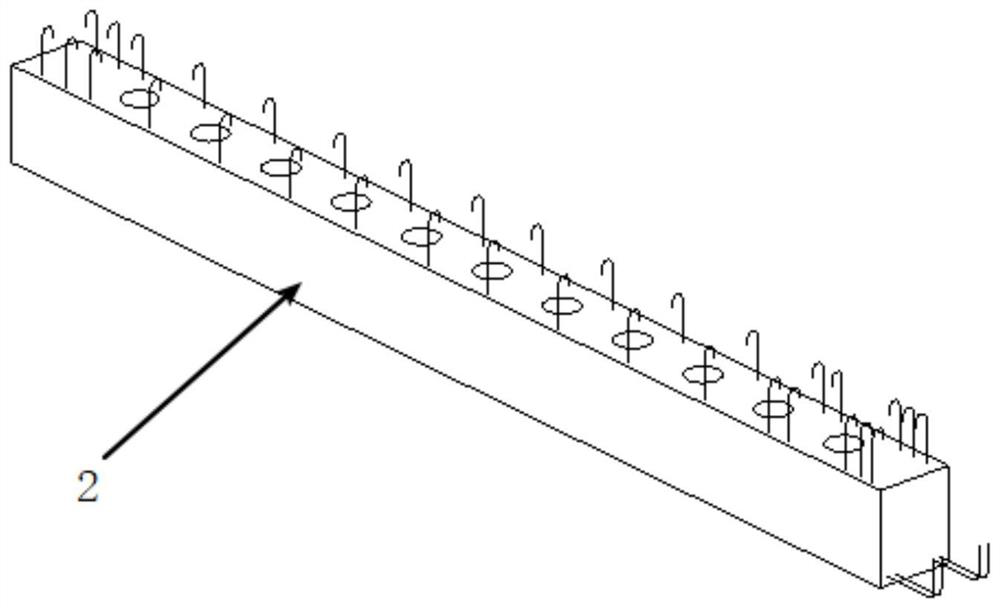

[0050] as attached figure 2 Shown: the porous prefabricated composite beam 2 is a prefabricated concrete beam with holes evenly distributed vertically;

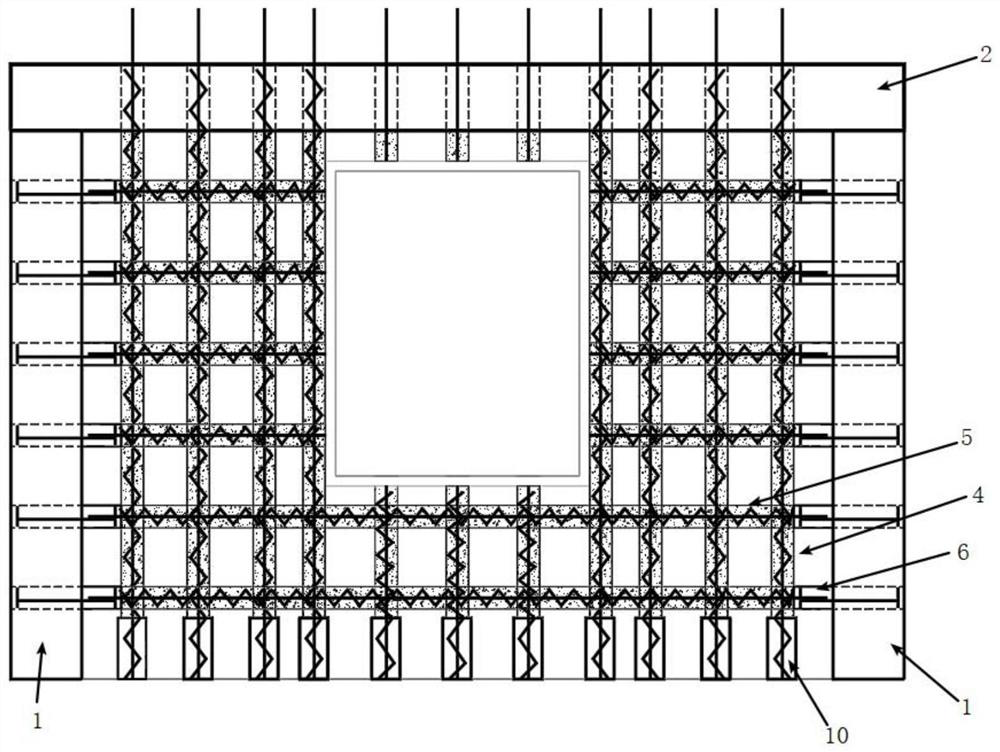

[0051] as attached image 3Shown: the prefabricated ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com