High-integration-level high-speed wind generating set

A wind power generation unit, a highly integrated technology, applied in the direction of wind motor combination, wind engine, wind power generation, etc., can solve the problems of insufficient integration of transmission chain, failure of bearing life, oil leakage of gearbox, etc., and achieve the integration of transmission chain High, low cost, avoiding the effect of the risk of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

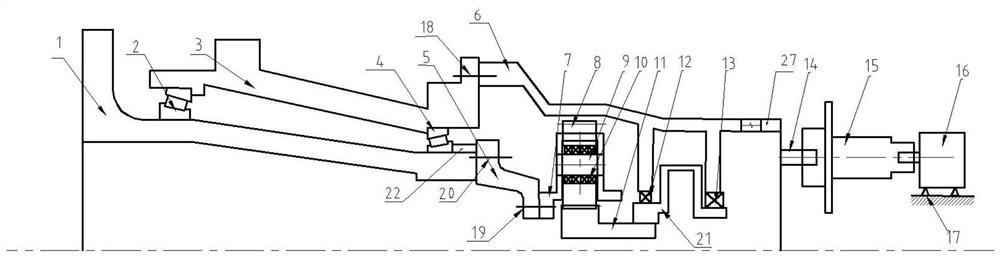

[0030] like figure 1 , figure 2 In the embodiment shown, a high-speed wind turbine with high integration is characterized in that, the high-speed wind turbine with high integration comprises: a main shaft 1, one end of the main shaft is fixedly connected with the impeller; a gear transmission assembly, the The gear transmission assembly includes an input end and an output end 14, the input end of the gear transmission assembly is fixedly connected with the other end of the main shaft; a generator 16, the input shaft of the generator is fixedly connected with the output end of the gear transmission assembly .

[0031] The gear transmission assembly includes a first-stage planetary gear 8, a first-stage sun gear 11 and a first-stage planetary carrier 7, the first-stage planetary carrier is the input end of the gear transmission assembly, and the first-stage planetary carrier is connected to the main shaft. Fixed connection.

[0032] The first-stage planet carrier is fixedly ...

Embodiment 2

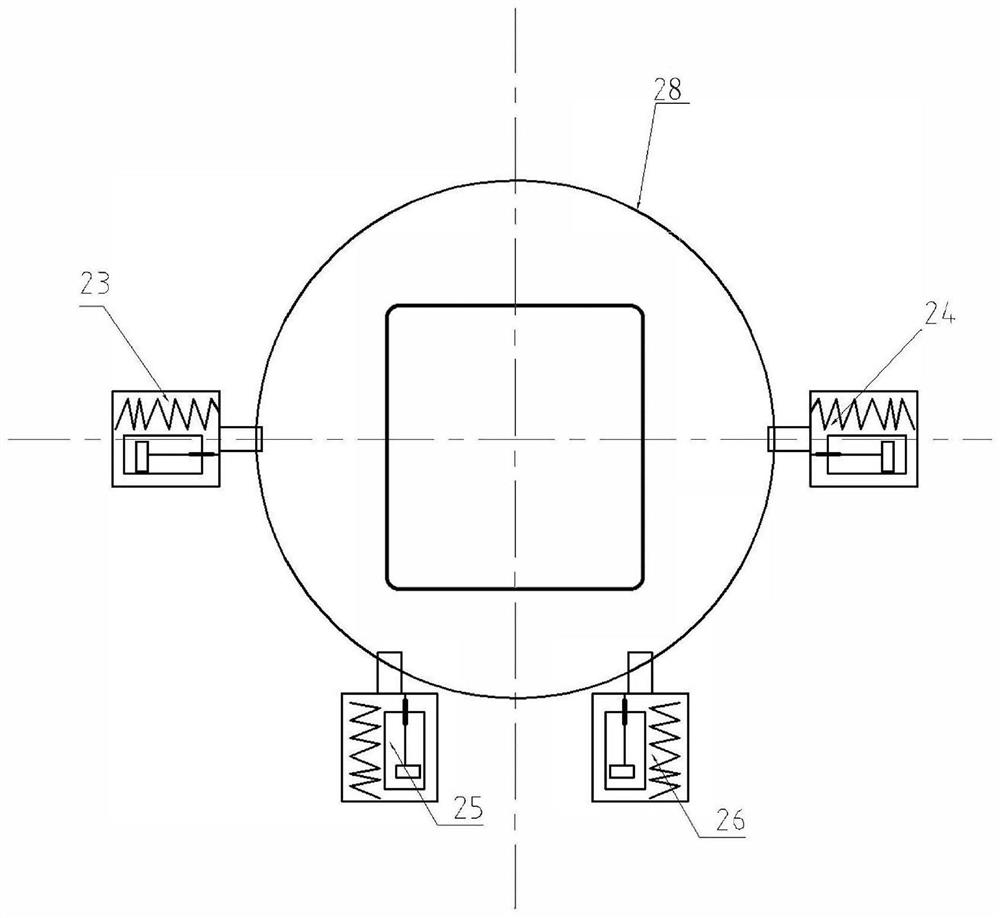

[0046] The difference from the first embodiment is that a shock absorber bracket 28 is fixed on the outer side of the gear box, the inner side of the shock absorber bracket fits the outer contour of the gear box, and the outer contour of the shock absorber bracket is circular, so the outer contour of the shock absorber bracket is circular. The plurality of shock absorbers are evenly spaced on the outer edge of the shock absorber bracket, and the shock absorber bracket is provided with a plurality of hollow areas.

[0047] The circular shock absorber bracket can better transmit the force, so that the sudden vibration is evenly transmitted to each shock absorber, and the hollow area set on the shock absorber bracket can provide deformation space to prevent the reduction box body when the vibration is too large. cause damage and deformation.

[0048] Therefore, the present invention has the following beneficial effects: (1) Compared with the prior art, the transmission chain of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com