Water-based adhesive with low glass transition temperature as well as preparation method and application of water-based adhesive

A technology of glass transition and transition temperature, applied in monocarboxylate copolymer adhesives, adhesive types, photovoltaic power generation, etc., can solve problems such as long drying time, slow film forming speed, and uneven sizing , to achieve the effect of low glass transition temperature, fast drying speed and good viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

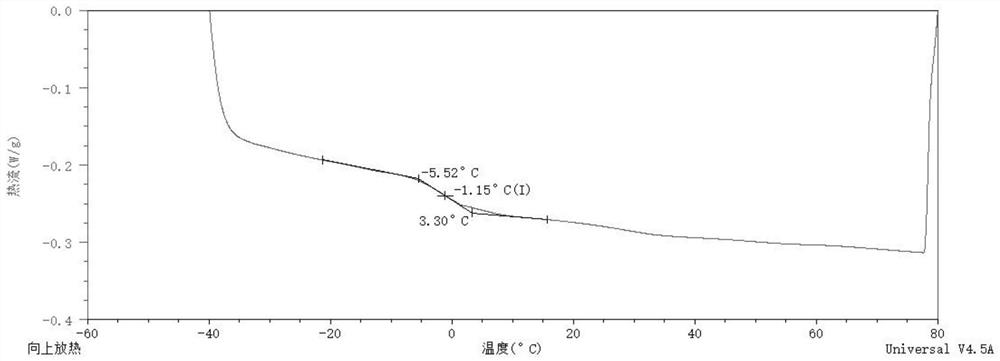

Embodiment 1

[0035] A preparation method of a water-based adhesive with a low glass transition temperature, comprising the steps of:

[0036] (1) Weighing: weigh vinyl acetate 330g; butyl acrylate 165g; acrylic acid 5.5g; polyvinyl alcohol 17-88, 35.0g; C12-14 secondary alcohol polyoxyethylene ether 27.5g; ammonium persulfate 1g; lemon 25g of triethyl acid; 4g of sodium bicarbonate, for use;

[0037] (2) the water of ammonium persulfate and 10g is mixed with ammonium persulfate aqueous solution;

[0038] Sodium bicarbonate and 36g of water are mixed with sodium bicarbonate aqueous solution;

[0039] Mixing vinyl acetate, butyl acrylate and acrylic acid uniformly to obtain a monomer mixed solution;

[0040] (3) Add 17-88 g of polyvinyl alcohol and 743 g of water to the reaction vessel, heat to 90°C in a water bath under stirring (280r / min), and keep the temperature at 90°C for 1 h to completely dissolve the polyvinyl alcohol to obtain a polyvinyl alcohol. Vinyl alcohol solution; the poly...

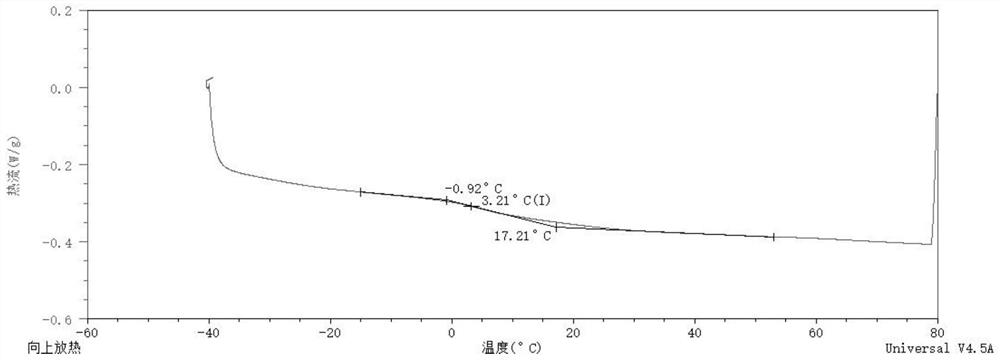

Embodiment 2

[0047] A preparation method of a water-based adhesive with a low glass transition temperature, comprising the steps of:

[0048] (1) Weighing: weigh vinyl acetate 320g; butyl acrylate 120g; acrylic acid 4.0g; polyvinyl alcohol 17-88, 31.1g; C12-14 secondary alcohol polyoxyethylene ether 25.0g; ammonium persulfate 0.9g; Triethyl citrate 22.0g; Sodium bicarbonate 3.5g, for use;

[0049] (2) the water of ammonium persulfate and 9g is mixed with ammonium persulfate aqueous solution;

[0050] Sodium bicarbonate and 31.5g water are mixed with sodium bicarbonate aqueous solution;

[0051] Mixing vinyl acetate, butyl acrylate and acrylic acid uniformly to obtain a monomer mixed solution;

[0052] (3) Add polyvinyl alcohol 17-88 and 660.0g of water into the reaction vessel, heat to 90°C in a water bath under stirring conditions (280r / min), and keep the temperature at 90°C for 1 hour to completely dissolve the polyvinyl alcohol, and obtain polyvinyl alcohol solution; the polyvinyl al...

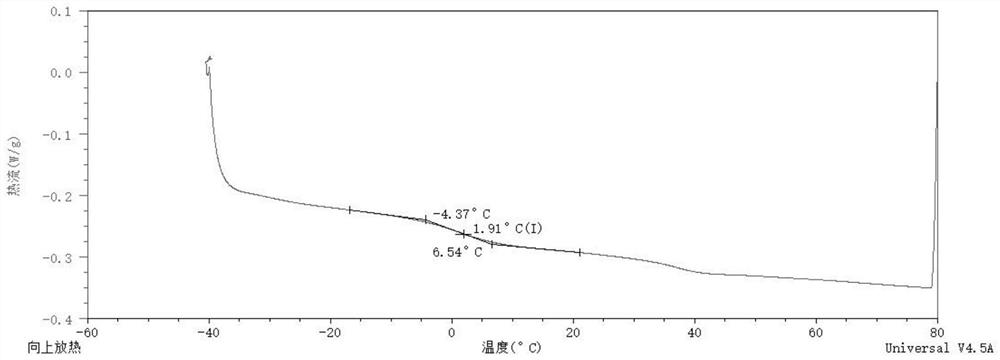

Embodiment 3

[0059] A preparation method of a water-based adhesive with a low glass transition temperature, comprising the steps of:

[0060] (1) Weighing: weigh vinyl acetate 310g; butyl acrylate 155g; acrylic acid 5.2g; polyvinyl alcohol 17-88, 33.0g; C12-14 secondary alcohol polyoxyethylene ether 25.9g; ammonium persulfate 0.94g; Triethyl citrate 23.5g; Sodium bicarbonate 3.8g, for use;

[0061] (2) the water of ammonium persulfate and 9.4g is mixed with ammonium persulfate aqueous solution;

[0062] Sodium bicarbonate and 34.2g of water are mixed with sodium bicarbonate aqueous solution;

[0063] Mixing vinyl acetate, butyl acrylate, and acrylic acid uniformly to obtain a monomer mixed solution;

[0064] (3) Add polyvinyl alcohol 17-88 and 700.3 g of water into the reaction vessel, heat to 90°C in a water bath under stirring conditions (280r / min), and keep the temperature at 90°C for 1 hour to completely dissolve the polyvinyl alcohol, and obtain polyvinyl alcohol solution; the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com