A kind of rosin-based thiolated polyvinyl chloride comb polymer and its preparation method and application

A technology of rosin-based mercaptan and comb-like polymer, which is applied in the field of rosin-based mercaptanized polyvinyl chloride comb-like polymer and its preparation, can solve the problems of PVC product function decline, endangering human health, and polluting the environment, achieving The effect of good product quality, less toxic and side effects, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

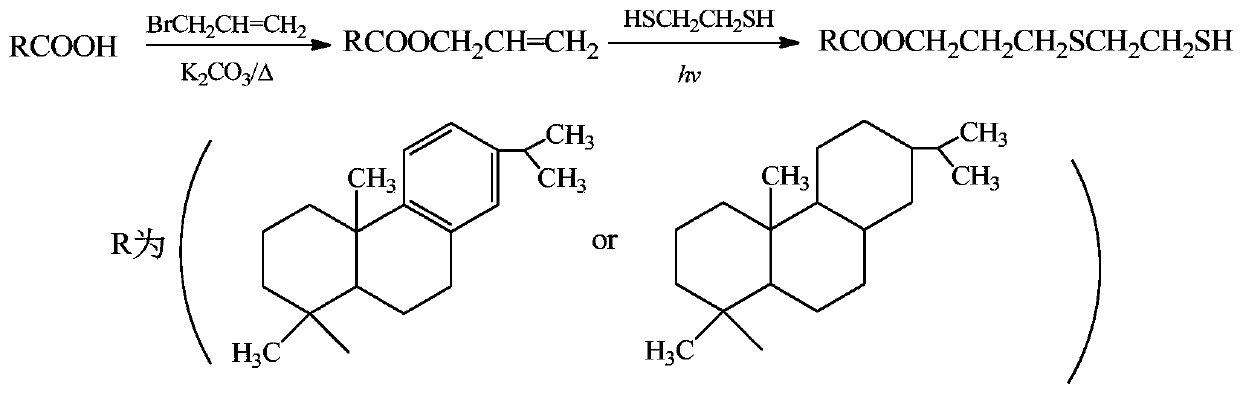

[0031] In the embodiment of the present invention, the synthetic method of the polyvinyl chloride comb polymer of dehydroabietyl mercaptan needs to go through the following process: 2 Under protection, 30g of dehydroabietyl mercaptan was added into the sodium methoxide-methanol system (methanol 100mL) at a molar ratio of 1:1 to sodium methoxide, and stirred under reflux at 70°C for 10h. After the reaction was completed, the solvent methanol was distilled off under reduced pressure. A crude product of sodium dehydroabietyl mercaptide was obtained. The crude product was repeatedly washed with petroleum ether to remove unreacted mercaptan, filtered, and vacuum-dried at 60°C for 4 hours to obtain a yellowish solid of sodium dehydroabietyl mercaptan. in N 2 Under protection, dissolve PVC in THF, add sodium dehydroabietyl mercaptan with a molar ratio of 0.2 to chlorine atoms, react at 50°C for 4 hours, and the reaction is over, pour the mixture into methanol to precipitate and wash...

Embodiment 2

[0034] In the embodiment of the present invention, the synthetic method of the polyvinyl chloride comb polymer of dehydroabietyl mercaptan needs to go through the following process: 2 Under protection, add 30g of dehydroabietyl mercaptan into the sodium ethoxide-ethanol (100 mL of ethanol) system at a molar ratio of 1:1 to sodium ethoxide, and reflux and stir at 70°C for 10 hours. After the reaction, the solvent ethanol is distilled off under reduced pressure , to obtain the crude product of sodium dehydroabietyl mercaptide. The crude product was repeatedly washed with petroleum ether to remove unreacted mercaptan, filtered, and vacuum-dried at 60°C for 4 hours to obtain a yellowish solid of sodium dehydroabietyl mercaptan. in N 2Under protection, dissolve PVC in THF, add sodium dehydroabietyl mercaptan with a molar ratio of 0.5 to chlorine atoms, react at 50°C for 6 hours, and the reaction ends. Drying for 24 hours under the hood to obtain a white solid dehydroabietyl-thiol...

Embodiment 3

[0037] In the embodiment of the present invention, the synthetic method of the polyvinyl chloride comb polymer of hydrogenated rosin-based mercaptan needs to go through the following process: 2 Under protection, add 30g of hydrogenated abietyl mercaptan into the sodium carbonate-cyclohexanone (cyclohexanone 100mL) system at a molar ratio of 1:1 to sodium carbonate, stir at 100°C for 10h, and distill off under reduced pressure after the reaction Solvent cyclohexanone to obtain the crude product of hydrogenated abietyl mercaptan sodium. The crude product was repeatedly washed with petroleum ether several times to remove unreacted mercaptan, filtered, and vacuum-dried at 60°C for 4 hours to obtain a white-yellow hydrogenated abietyl sodium mercaptide solid. in N 2 Under protection, dissolve PVC in THF, add sodium hydrogenated abietyl mercaptide with a molar ratio of 1 to chlorine atom, react at 50°C for 6 hours, and the reaction ends. After drying for 24 hours, a hydrogenated r...

PUM

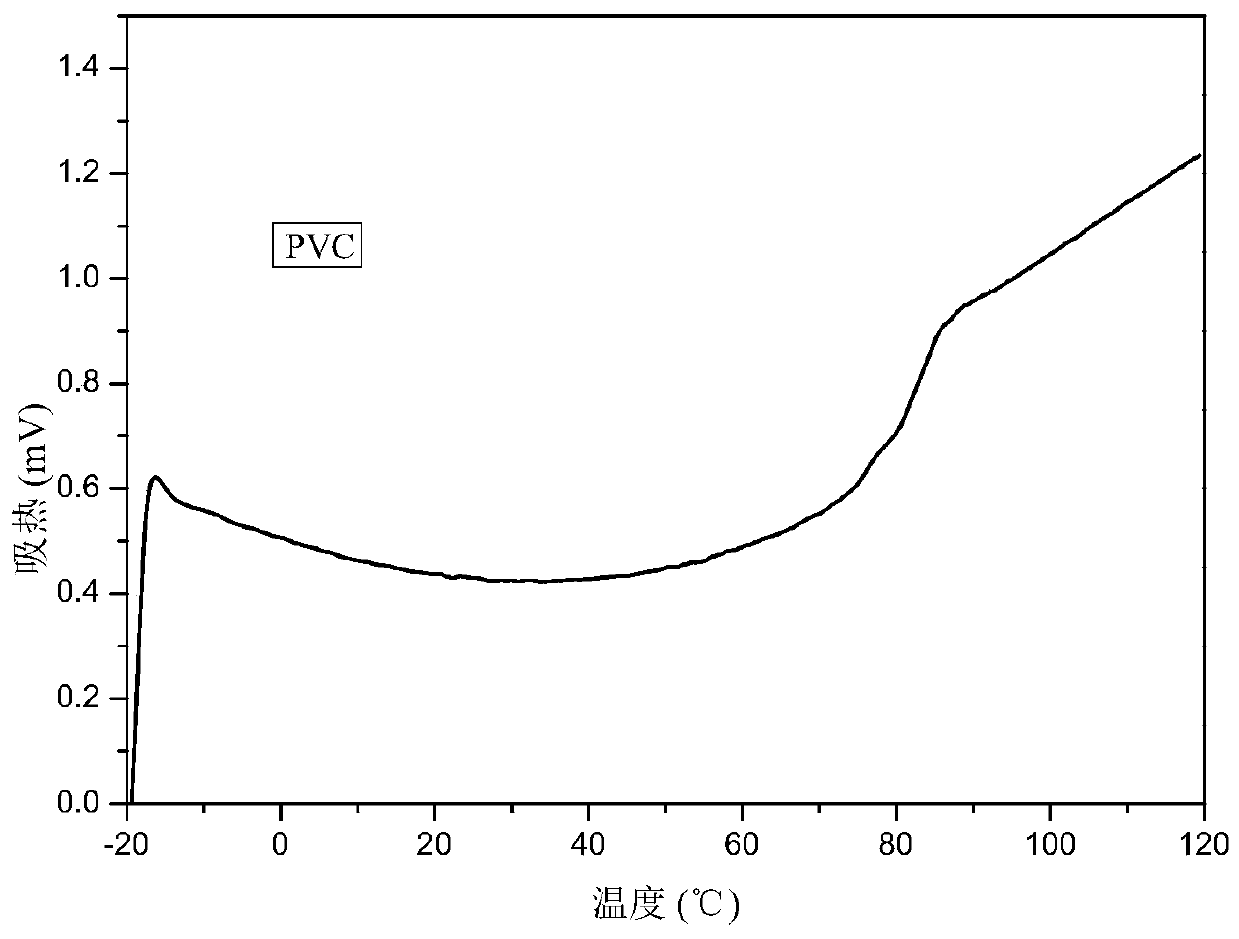

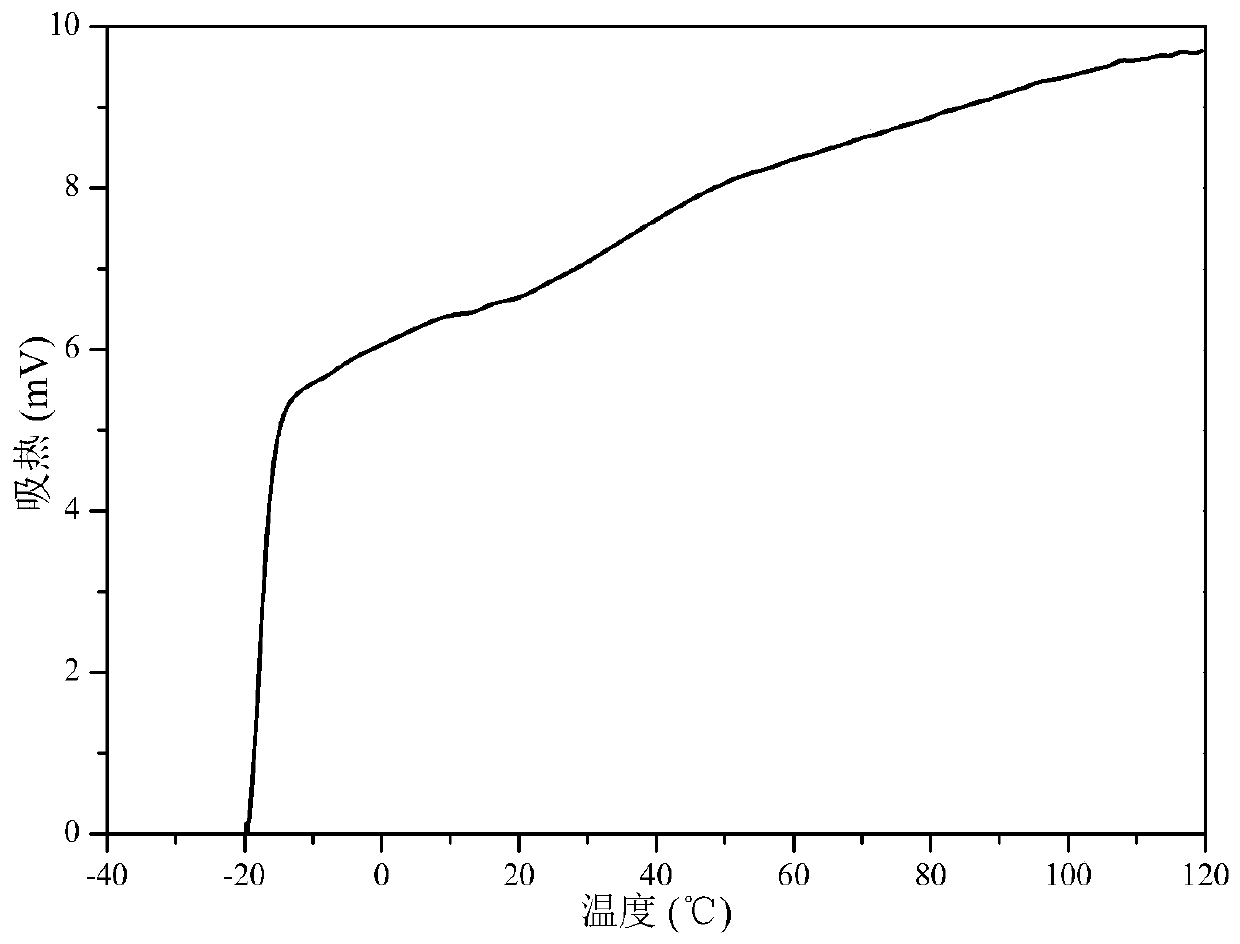

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com