Preparation method of magnesium oxyferric phosphate composite cement-based 3D printing material

A composite cement and 3D printing technology, applied in the field of 3D printing materials, can solve the problems of limiting the application range of 3D printing materials, the fundamental properties of cohesiveness or setting time have not been improved, and achieve the promotion of hydration, long service life, The effect of rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In Example 1, the composite cement base was 15 grams, the fine aggregate was 6 grams, and the admixture was 79 grams.

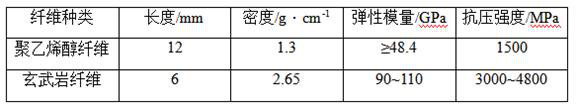

[0035] The formula composition of the composite cement base is: 1800g of light-burned magnesium oxide powder, 200g of magnesium sulfate heptahydrate, 3600g of water, and 180g of iron phosphate. The formulation of the admixture is as follows: 25g of polycarboxylate water reducer, 23g of thickener, 17g of thixotropic agent, and 35g of reinforcing material.

[0036] 3D printing material raw material composition: 2%~80% composite cement base, 1%~8% fine aggregate, and the balance is an admixture composition for iron phosphate magnesium oxysulfide composite cement base; admixture composition : Water reducing agent accounts for 6%~30%, thickener accounts for 5%~25%, thixotropic agent accounts for 3%~25%, and reinforcing material accounts for 20%~45%.

[0037] The preparation method of the 3D printing material in Example 1 includes the following steps:

[003...

Embodiment 2

[0044] In Example 2, the composite cement base was 25 grams, the fine aggregate was 5 grams, and the admixture was 70 grams.

[0045] The formula composition of the composite cement base is the same as that of Example 1. The formula composition of the admixture is: 15g of polycarboxylate water reducer, 23g of thickener, 20g of thixotropic agent, and 42g of reinforcing material.

[0046] The preparation method of Example 2 is the same as that of Example 1. The strength is 41.2MPa, which is 17.7% higher than ordinary magnesium oxysulfate cement

Embodiment 3

[0048] In Example 3, the composite cement base was 35 grams, the fine aggregate was 6 grams, and the admixture was 59 grams.

[0049] The formula composition of the composite cement base is the same as that of Example 1. The formula composition of the admixture is: 25g of polycarboxylate water reducer, 22g of thickener, 25g of thixotropic agent, and 28g of reinforcing material.

[0050] The preparation method of Example 3 is the same as that of Example 1. The strength is 45.2MPa, which is 30.0% higher than ordinary magnesium oxysulfate cement

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com