Splicing type grating floor production equipment

A kind of production equipment and splicing technology, which can be applied to household appliances, other household appliances, household components, etc., can solve the problems affecting the quality of the grid plate, achieve the effects of small stress, large contact area, and increased demoulding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means of the present invention, creative features, to achieve the object and efficacy easy to understand, the following in conjunction with specific embodiments, further elaborated on the present invention.

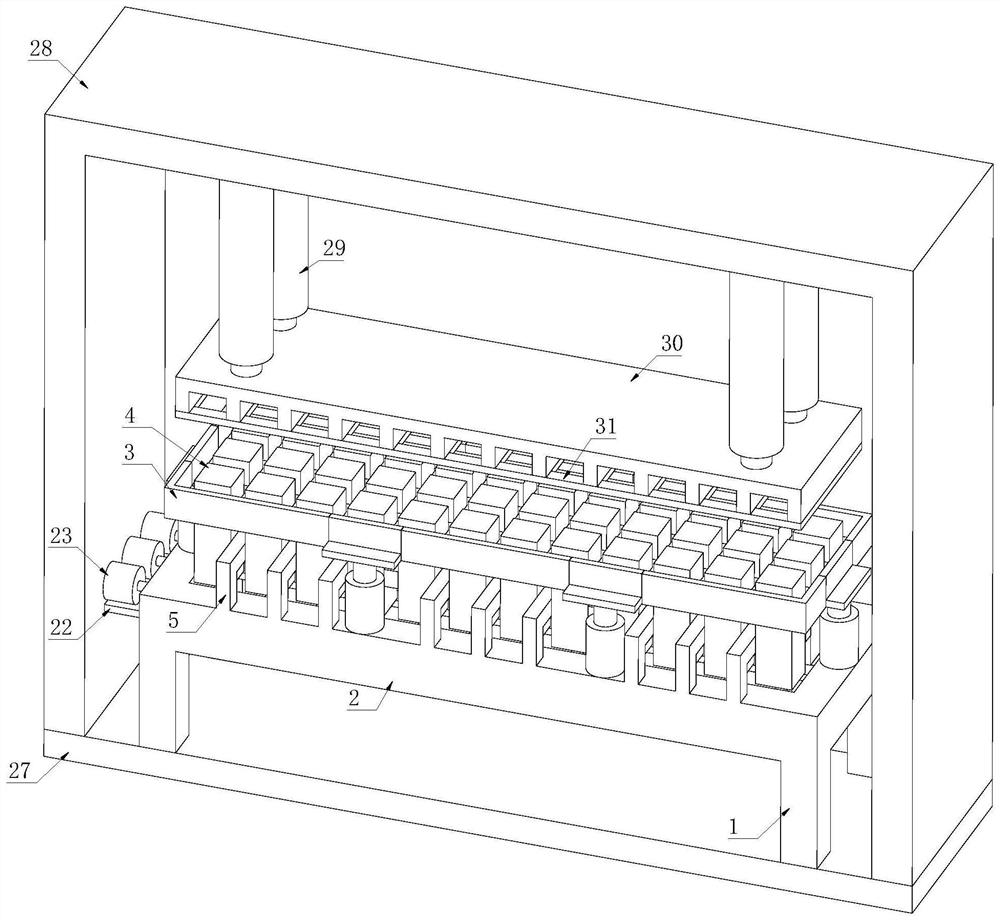

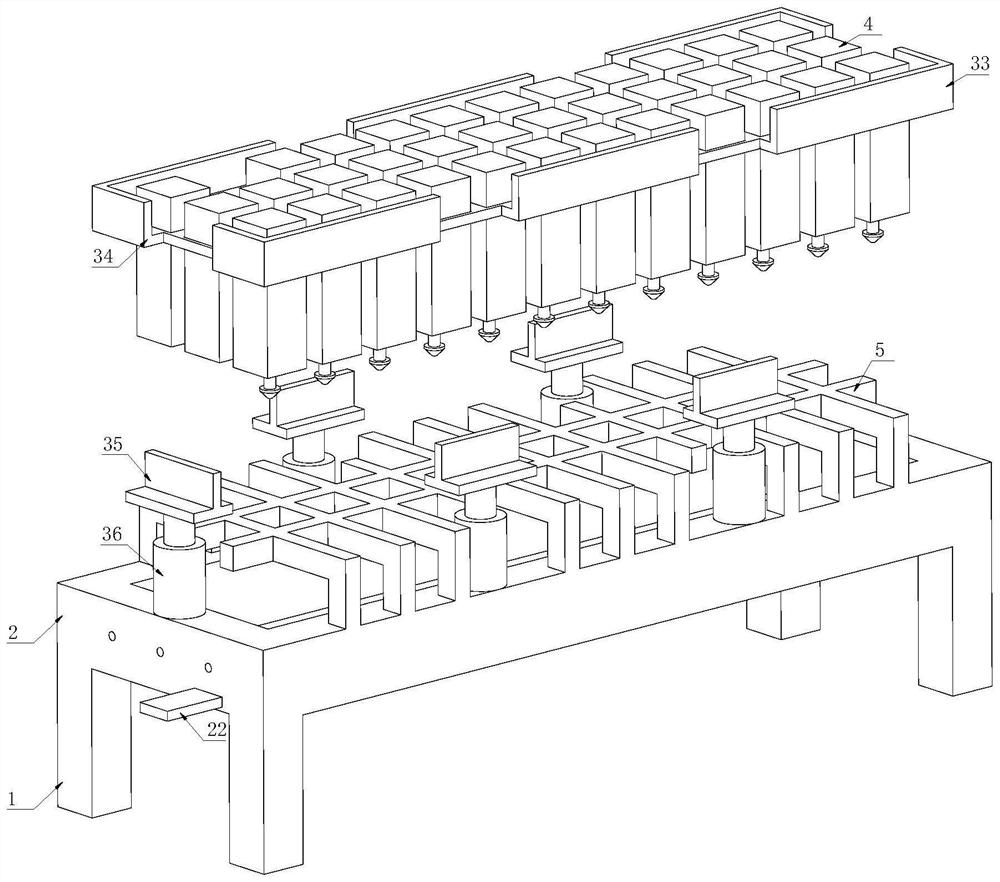

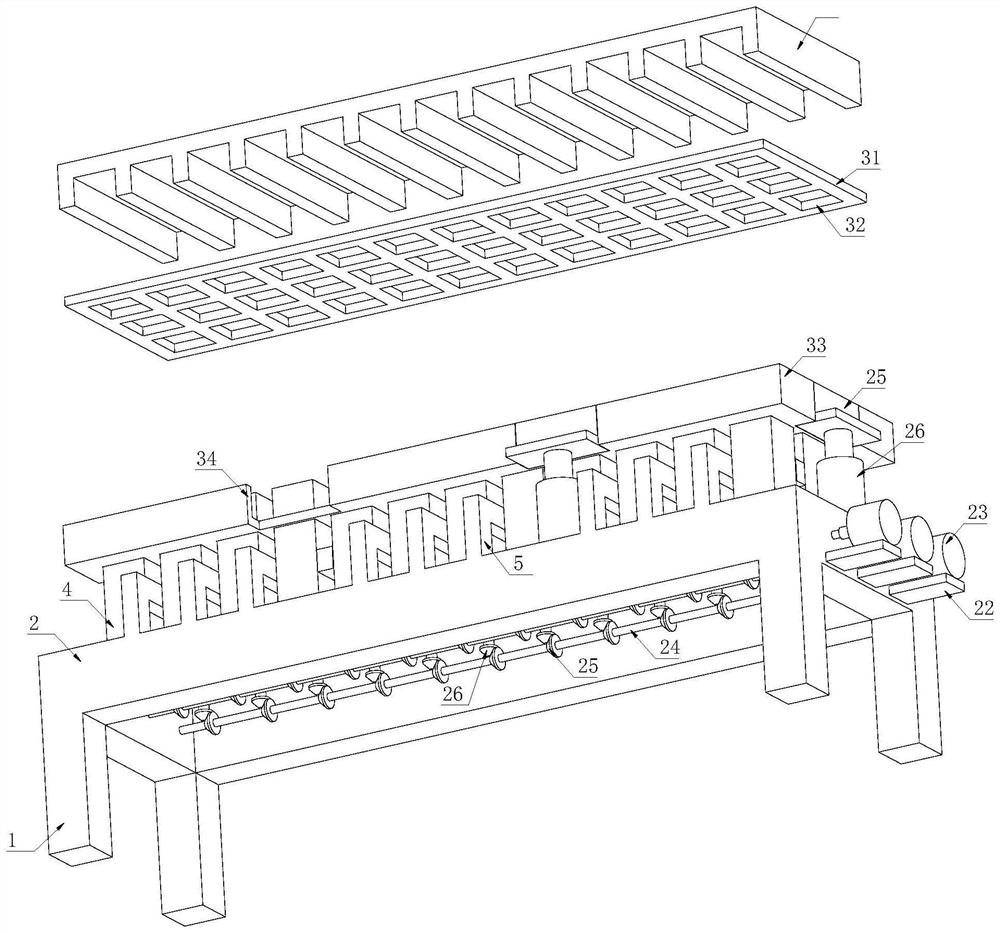

[0030] as Figure 1- Figure 7 As shown, a spliced grating floor production apparatus of the present invention, comprising a support leg 1, the support leg 1 top fixed connection is connected to a rectangular box 2, the rectangular box 2 top fixed connection is connected to a reservoir structure for placing epoxy resin 3, the reservoir structure 3 internal vertically runs through a plurality of rectangular columns in a linear array distribution 4, the plurality of rectangular columns 4 is fixed between the support frame 5, the support frame 5 is fixed to the top surface of the rectangular frame 2 fixed connection, the rectangular column 4 bottom is opened with a cylindrical blind hole 6, The rectangular column 4 is provided with a vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com