Novel brick making machine

A brick making machine and a new type of technology, applied in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of uneven mixing of fillers, affecting the production quality of brick bodies, and uneven surface of the blank area, so as to improve the brick body. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

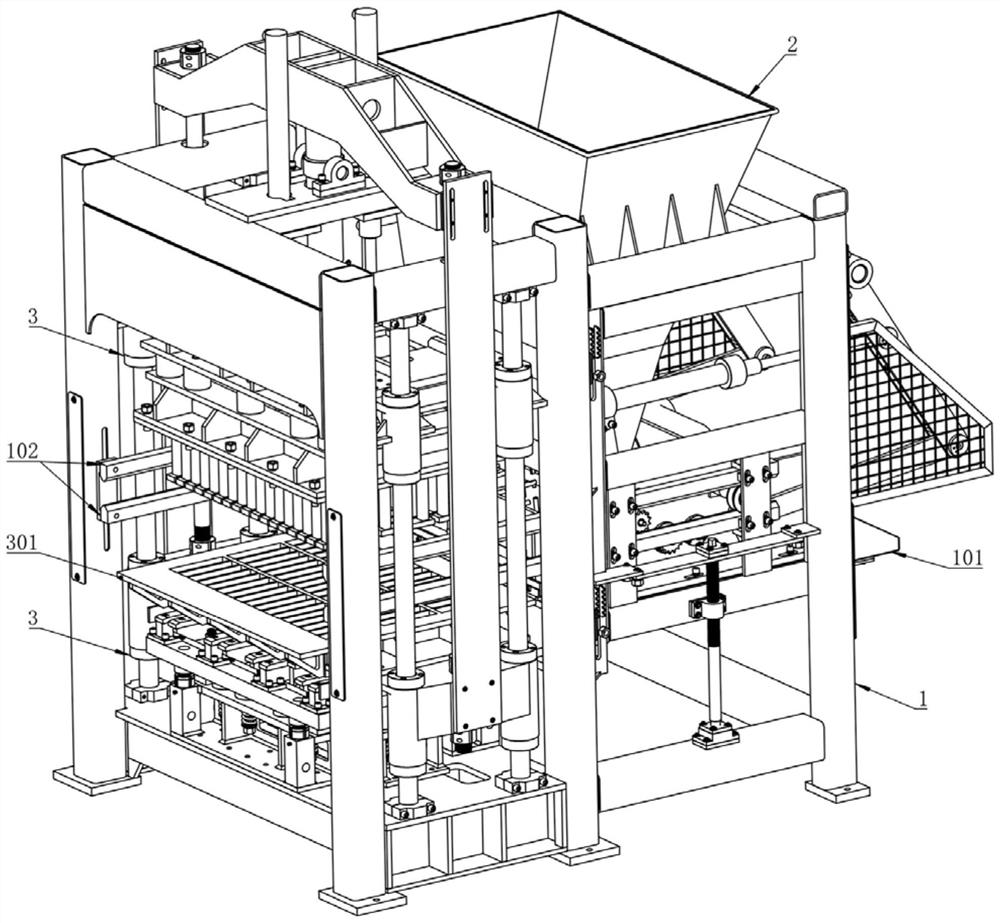

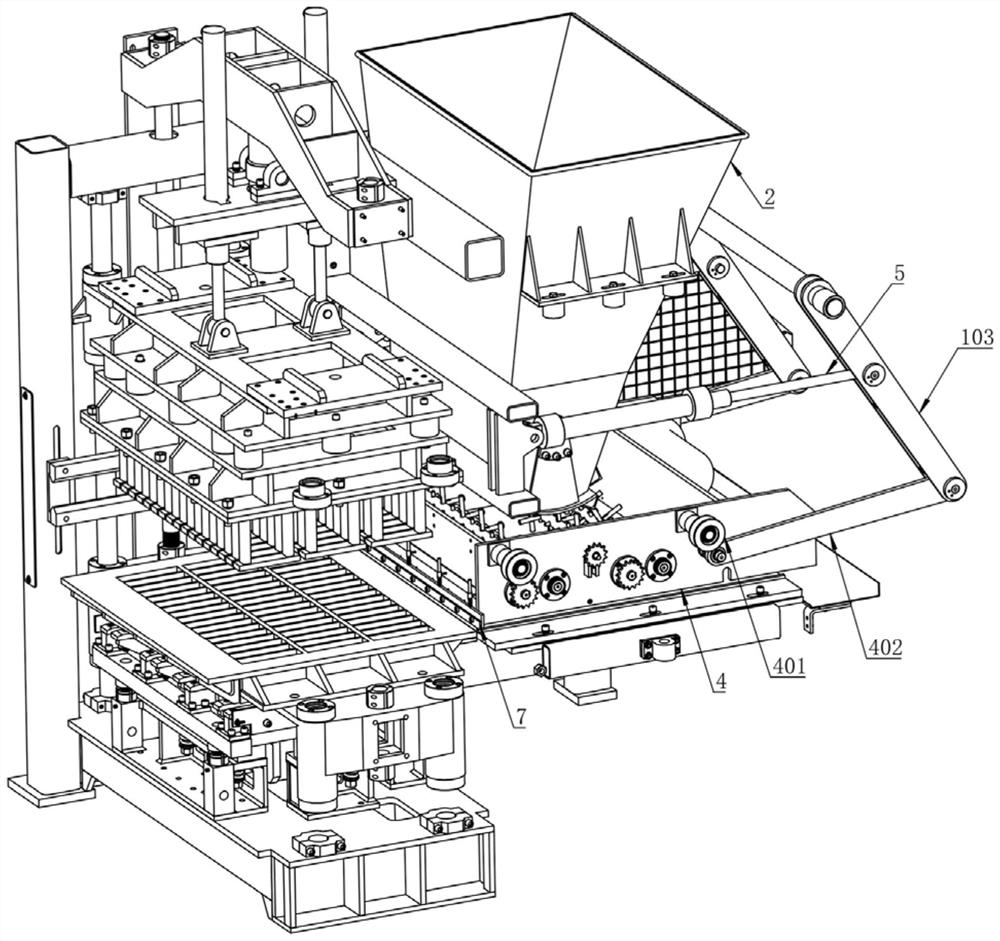

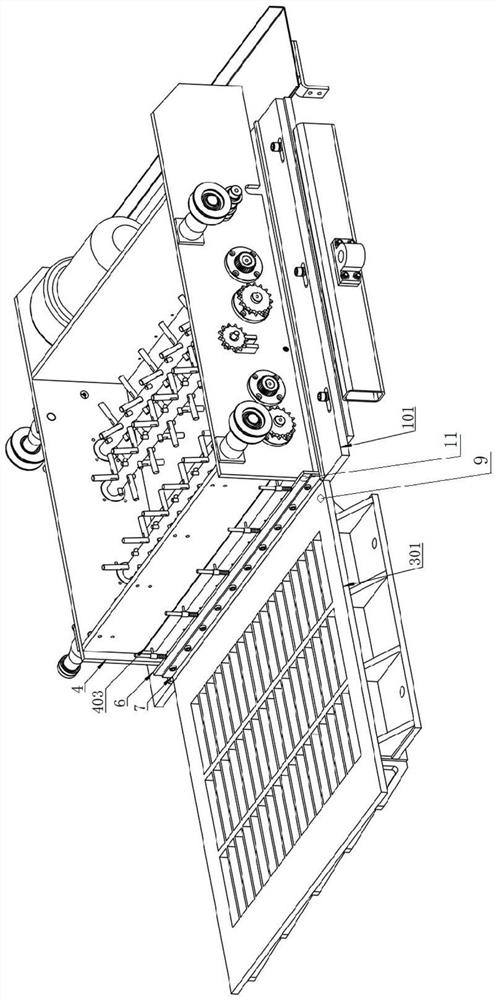

[0031] Specific embodiment one: combination Figure 1-5 As shown, a new type of brick making machine, comprising a frame 1, hopper 2, press molded brick set 3, mixing drawer 4, cylinder 5, substrate 6 and rubber scraper 7; the die brick group 3 is provided in the left position of the frame 1; the molded brick group 3 is provided with a mold platform 301 in the middle of the frame 1; the frame 1 is fixed in the middle of the right side of the loading platform 101; the mixing drawer 4 is provided on the feeding platform 101; the hopper 2 is fixed on the rack 1 above the feeding platform 101 The stirring drawer 4 is provided with pulleys 401 on both sides; the frame 1 is provided with a sliding rail 102 on both sides of the inner side; the pulley 401 slide is connected inside the slide rail 102; the mixing drawer 4 at both ends of the right end of the shaft is connected to the connecting rod 402; the frame 1 on the right side of the upper two ends of the spindle is connected to the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com