Preparation method of novel high-temperature-resistant waterproof branch cable assembly

A branch cable, high-temperature-resistant technology, applied in the direction of cable/conductor manufacturing, insulated cables, electrical components, etc., can solve the problems of penetration, adhesive adhesion, etc., and achieve the effect of improving waterproof performance and improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

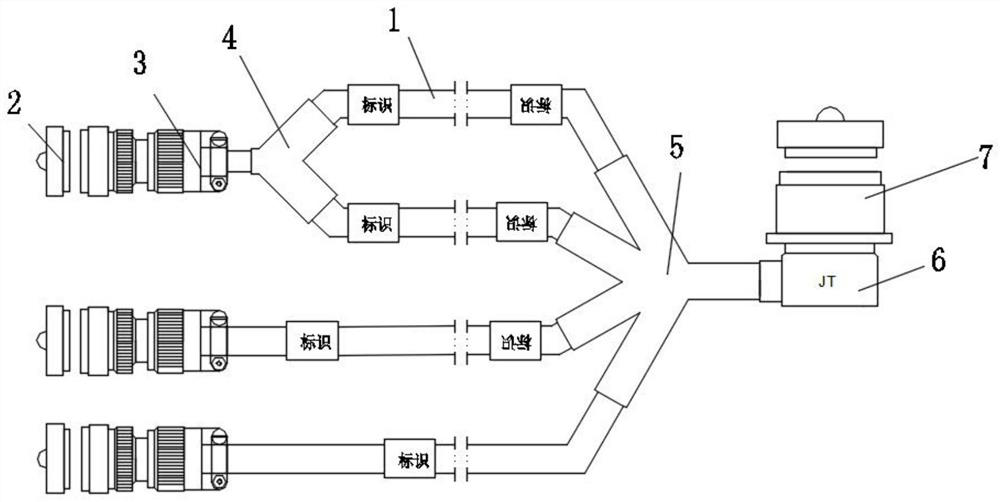

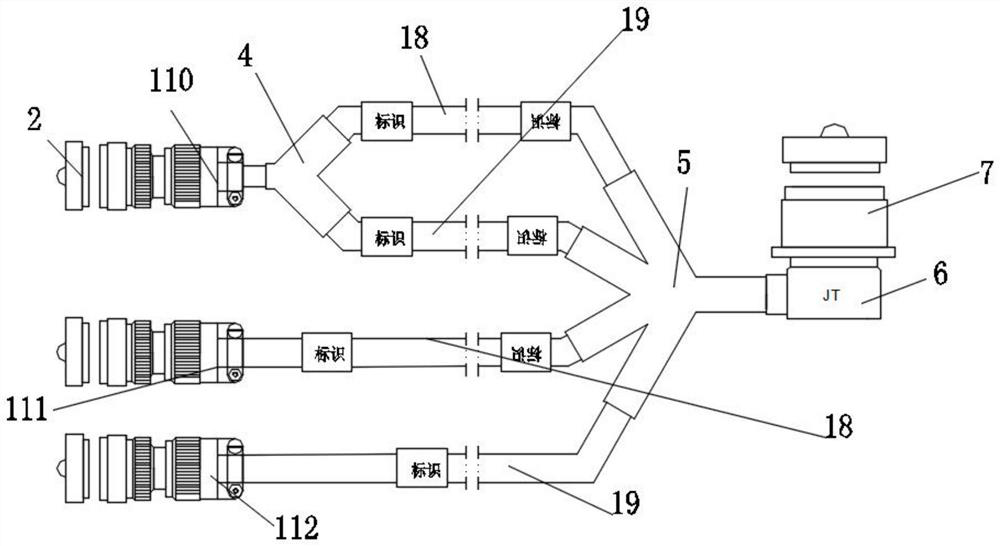

[0028] It is one of the specific implementation modes of the present invention: refer to the accompanying drawings.

[0029] In this embodiment, a new type of high temperature resistant and waterproof branch cable assembly includes multiple groups of cables 1 and connectors 2, one end of several cables 1 is respectively connected with a tail cover 3, and one end of the remaining cables 1 is respectively passed through The fork sleeve 4 is connected with a tail cover 3, each of the tail cover 3 is connected with a connector 2, and the other end of each of the cables 1 is respectively connected with a JT plug 6 through a molded fork sleeve 5, and the plug of the JT plug 6 Connector 2 is connected to the joint end.

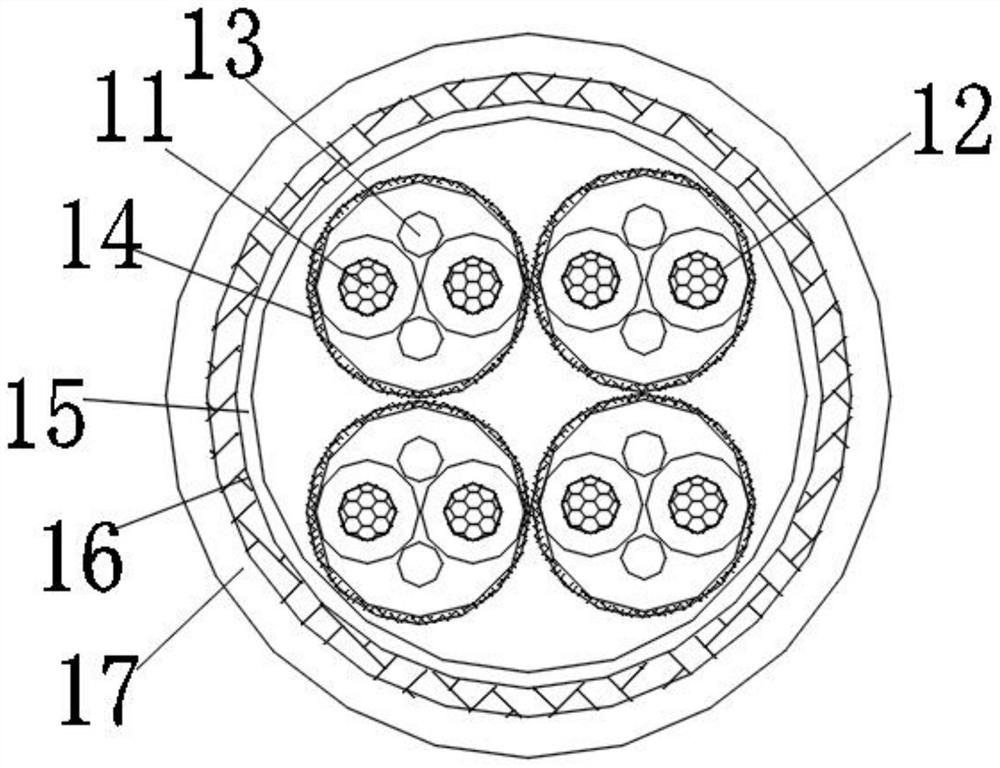

[0030] Further, the cable 1 includes a silver-plated round copper wire conductor 11 extruded with a layer of fluoroplastic insulating layer 12 to form an insulated core, and two insulated cores are stranded with two tensile ropes 13 to form a cable core. A layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com