Method for testing safety performance of rigid heightened guardrail

A technology of safety performance and test method, which is applied in the field of testing the safety performance of rigid heightened guardrails, can solve problems such as lack of safety performance of rigid heightened guardrails, and achieve reliable test results, simple steps, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

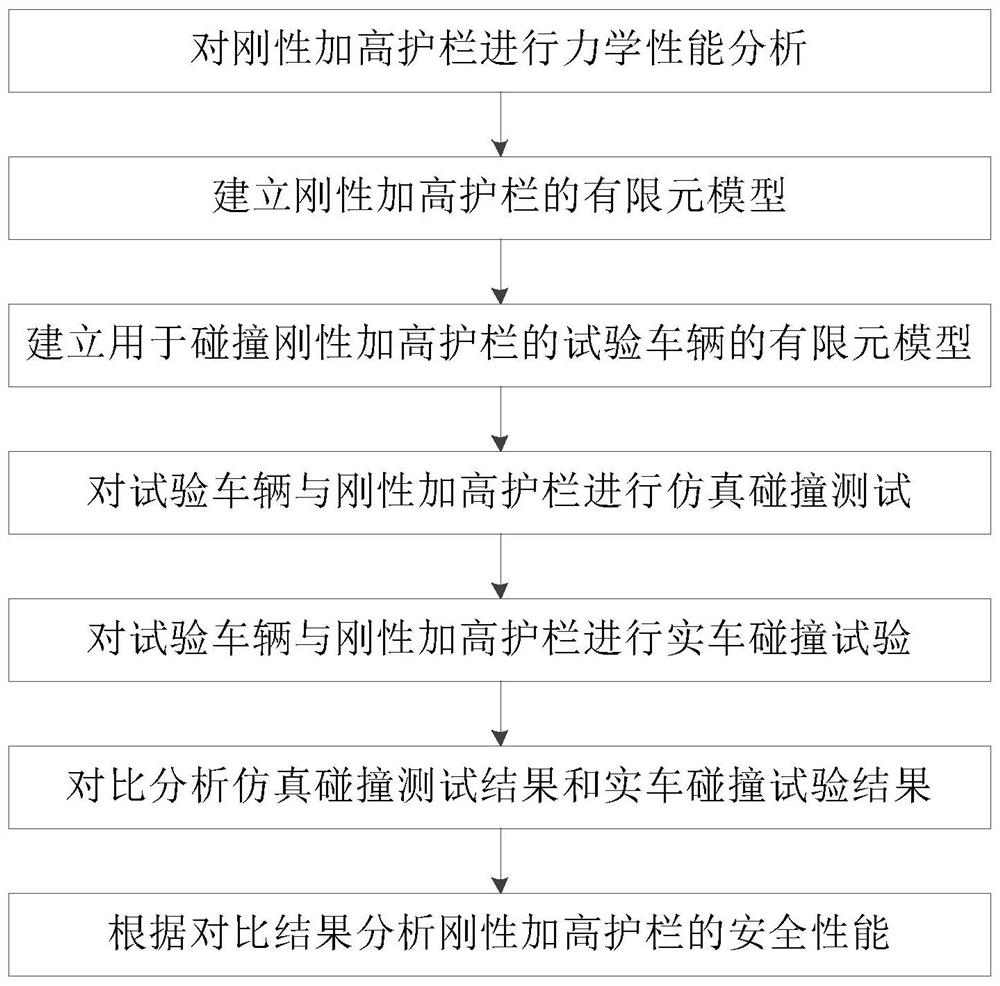

[0034] Such as figure 1 Shown, the testing method of rigid heightened guardrail safety performance of the present invention comprises:

[0035] Step 1. Carry out mechanical performance analysis on the rigid heightened guardrail;

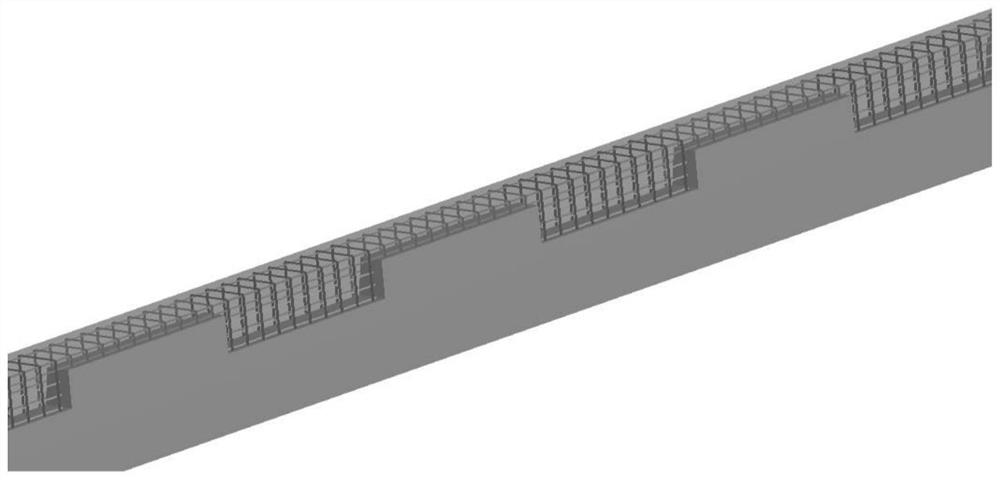

[0036] Step 2, according to the mechanical properties of the rigid heightening guardrail, establish the finite element model of the rigid heightening guardrail;

[0037] Step 3, establishing the finite element model of the test vehicle used for collision with the rigid heightened guardrail;

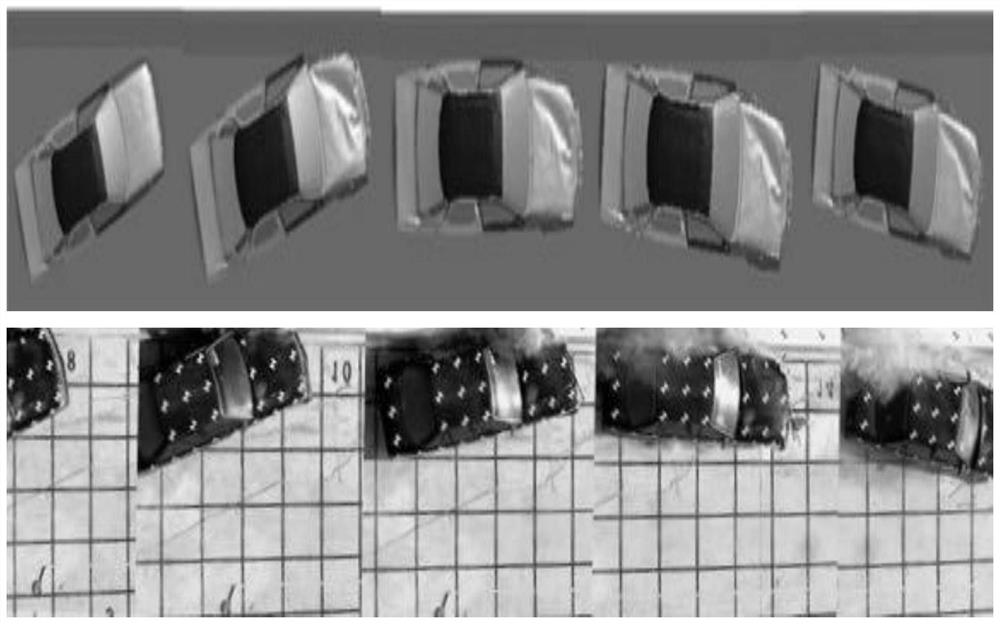

[0038] Step 4. Carry out a simulated collision test between the test vehicle and the rigid heightened guardrail;

[0039] Step 5. Carry out a real vehicle collision test between the test vehicle and the rigid heightened guardrail;

[0040] Step 6. Compare and analyze the results of the simulated crash test and the results of the real vehicle crash test;

[0041] Step 7: Analyze the safety performance of the rigid heightened guardrail according to the compari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com